|

|

|

|

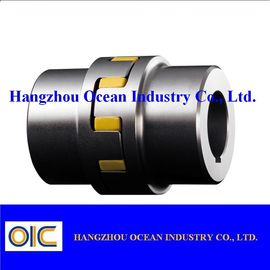

Industrial Machinery Flexible Metal CS Type Couplings Bolt on Type With 10000 RPM Max Speed

| Max Torque: | 500 Nm | Vibration Damping: | Yes |

|---|---|---|---|

| Temperature Range: | Up To 200°C | Color: | Silver |

| Material: | Stainless Steel | Max Speed: | 10,000 RPM |

| Installation Method: | Bolt-on | Size: | Various Sizes Available |

Product Description:

Our Flexible Couplings come in various sizes, ensuring that you'll find the perfect fit for your needs. Whether you need a compact coupling for a small machine or a larger one for heavy-duty applications, we've got you covered.

The connection type for our couplings is flange, which is a popular choice for many industries. Flange connections are known for their stability and ease of installation, making them the go-to option for professionals worldwide.

Our Flexible Couplings are manufactured to the highest standards, and we are proud to say that they come with ISO 9001 and CE certifications. These certifications guarantee that our couplings meet strict quality control standards, ensuring that you get the best product possible.

When it comes to temperature range, our Flexible Couplings can handle up to 200°C. This means that you can use them in a wide range of applications without worrying about damage due to high temperatures.

One of the standout features of our Flexible Couplings is their high torsional stiffness. This is thanks to the use of a flexible diaphragm coupling sleeve, which allows for smooth power transmission while maintaining the rigidity of the coupling. The diaphragm coupling sleeve is designed to be highly flexible, making it ideal for applications where misalignment and vibration are present.

Our Flexible Couplings are also available in grooved couplings, which are perfect for applications where space is limited. Grooved couplings are designed to be compact and easy to install, making them the ideal choice for small machines and tight spaces.

In conclusion, our Flexible Couplings are the perfect solution for all your power transmission needs. With their flange connection, ISO 9001 and CE certifications, wide temperature range, various sizes, and high torsional stiffness, you can be sure that you're getting a top-quality product. So why wait? Contact us today and see how our Flexible Couplings can help you!

Features:

- Product Name: CS type Couplings

- Torsional Stiffness: High

- Temperature Range: Up To 200°C

- Certifications: ISO 9001, CE

- Connection Type: Flange

- Size: Various Sizes Available

Our Flexible Couplings product is perfect for coupling hydraulic hoses with ease and flexibility. These couplings are also known as GR Couplings and have a high torsional stiffness, making them ideal for heavy-duty applications. With a temperature range of up to 200°C, our couplings are designed to withstand extreme temperatures. They come in various sizes to meet your specific needs, and are ISO 9001 and CE certified for quality assurance.

| Catalog | Fundamental Dimensions | Bolt | Keyway | wt Lbs |

||||

| OD | B | L | C | Size | Qty | |||

| CS-04 | 12 | 1/4 | 3/4 | 3/16 | #6-32 x1/8 | 2 | - | 0.06 |

| CS-05 | 5/8 | 5/16 | 1 | 1/4 | #10-24 x3/16 | - | 0.06 | |

| CS-06 | 3/4 | 3/8 | 1 | 1/4 | #10-24 x3/16 | - | 0.1 | |

| CS-08 | 1 | 1/2 | 11/2 | 3/8 | 1/4-20 x1/4 | - | 0.2 | |

| CS-10 | 11/4 | 5/8 | 2 | 1/2 | 1/4-20 x1/4 | - | 0.5 | |

| CS-10K | 11/4 | 5/8 | 2 | 1/2 | 1/4-20 x3/16 | 3/16 x3/32 | 0.5 | |

| CS-12 | 11/2 | 3/4 | 2 | 1/2 | 5/16-18 x1/4 | - | 0.8 | |

| CS-12K | 11/2 | 3/4 | 2 | 1/2 | 5/16-18 x1/4 | 3/16 x3/32 | 0.8 | |

| CS-14 | 13/4 | 7/8 | 2 | 1/2 | 5/16-18 x1/4 | - | 1 | |

| CS-14K | 13/4 | 7/8 | 2 | 1/2 | 5/16-18 x1/4 | 3/16 x3/32 | 1 | |

| CS-16 | 2 | 1 | 3 | 3/4 | 3/8-16 x3/8 | - | 1.9 | |

| CS-16K | 2 | 1 | 3 | 3/4 | 3/8-16 x3/8 | 1/4 x1/8 | 1.9 | |

| CS-18 | 21/8 | 11/8 | 3 | 3/4 | 3/8 x16 x3/8 | 1/4 x1/8 | 2.1 | |

| CS-18K | 21/8 | 11/8 | 3 | 3/4 | 3/8 x16 x1/8 | 1/4 x1/8 | 2.1 | |

| CS-20 | 21/4 | 11/4 | 4 | 1 | 3/8 x16 x3/8 | - | 3.1 | |

| CS-20K | 21/4 | 11/4 | 4 | 1 | 3/8 x16 x3/8 | 1/4 x1/8 | 3.1 | |

| CS-22 | 21/2 | 13/8 | 41/2 | 1 | 3/8 x16 x3/8 | - | 4.3 | |

| CS-22K | 21/2 | 13/8 | 41/2 | 1 | 3/8 x16 x3/8 | 5/16 x5/32 | 4.3 | |

Applications:

The MW flexible couplings are perfect for a variety of applications and scenarios. For instance, they are ideal for use in machines that require high-speed rotation, with a maximum speed of up to 10,000 RPM. This makes them an excellent choice for use in industrial applications where there is a need for high-speed machinery.

The connection type of the MW flexible couplings is flange, which means that they can be easily attached to a variety of different machines and equipment. This makes them a versatile choice for many different applications.

These flexible couplings are also highly resistant to corrosion, which means that they are perfect for use in harsh environments where there may be exposure to moisture or other corrosive materials. This makes them an excellent choice for use in marine applications or in environments where there are high levels of humidity.

The temperature range for these flexible couplings is up to 200°C, which means that they can be used in a variety of different temperature environments. This makes them an excellent choice for use in high-temperature environments such as ovens or other heat-generating machinery.

The MW flexible couplings are also ideal for use in a variety of different coupling scenarios. For instance, they are perfect for use in flexible coupling parts, as well as in drum gear couplings. This makes them a versatile choice for many different mechanical systems.

FAQ:

Q: What is a flexible coupling?

A: A flexible coupling is a mechanical device that connects two shafts together in order to transmit power while accommodating for minor misalignments between the two shafts.

Q: What brand of flexible couplings do you offer?

A: We offer flexible couplings manufactured by MW, a leading brand in the industry.

Q: Where are your flexible couplings made?

A: Our flexible couplings are made in China, the place of origin for MW products.

Q: What materials are your flexible couplings made of?

A: Our flexible couplings are made of various materials including stainless steel, aluminum, and polyurethane depending on the specific model.

Q: Can your flexible couplings accommodate high torque and high-speed applications?

A: Yes, our flexible couplings are designed to handle high torque and high-speed applications to ensure reliable and efficient power transmission.

![]()

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200