|

|

|

|

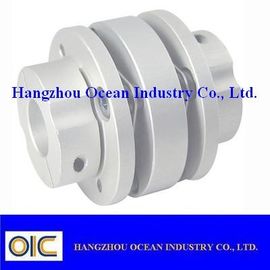

Silver Flange Connection Flexible Couplings for Speed Applications

| Misalignment Capacity: | ±3° | Type: | Flexible |

|---|---|---|---|

| Max Torque: | 500 Nm | Connection Type: | Flange |

| Material: | Stainless Steel | Vibration Damping: | Yes |

| Color: | Silver | Torsional Stiffness: | High |

Product Description:

Our Flexible Couplings are characterized by high torsional stiffness and excellent vibration damping properties, making them ideal for a range of applications where precision and reliability are critical. These couplings are designed to absorb shock and vibration, reducing wear on the connected equipment and increasing their lifespan. Additionally, the flexible design of these couplings allows them to compensate for shaft misalignment, minimizing the risk of damage to the connected equipment.

Our Flexible Couplings come in different types, including casing coupling, flange rigid coupling, and GR coupling. The casing coupling is a flexible coupling that connects two shafts that are offset and misaligned. It features a split design that allows for easy installation and maintenance. The flange rigid coupling is a type of flexible coupling that provides excellent torsional stiffness while still accommodating angular and axial misalignment. The GR coupling is a flexible coupling that is designed to transmit high torque while reducing shock and vibration.

Our Flexible Couplings are capable of operating within a temperature range of up to 200°C, making them suitable for use in a wide range of industrial applications. They are also designed to be bolted on, making installation easy and convenient. This installation method ensures that the coupling remains secure and stable, reducing the risk of damage to the connected equipment.

In summary, our Flexible Couplings are an excellent solution for applications that require high torsional stiffness, vibration damping, and flexibility. They are available in different types, including casing coupling, flange rigid coupling, and GR coupling, and can operate within a temperature range of up to 200°C. Their bolt-on installation method ensures that they remain secure and stable, reducing the risk of damage to the connected equipment.

Features:

- Product Name: Flexible Couplings

- Size: Various Sizes Available

- Torsional Stiffness: High

- Color: Silver

- Connection Type: Flange

- Corrosion Resistance: High

- Perfect for Agricultural Quick Couplings

- Compatible with GR Coupling

Technical Parameters:

| Coupling Type | Flexible Element Coupling |

| Application | Industrial Machinery |

| Installation Method | Bolt-on |

| Corrosion Resistance | High |

| Misalignment Capacity | ±3° |

| Color | Silver |

| Max Torque | 500 Nm |

| Certifications | ISO 9001, CE |

| Torsional Stiffness | High |

| Connection Type | Flange |

| Vibration Damping | Yes |

Applications:

The flexible couplings are also designed with a high torsional stiffness, providing a reliable connection between the shafts, even under harsh conditions. The MW flexible couplings are ISO 9001 and CE certified, ensuring that they meet industry standards for quality and safety.

The MW flexible couplings are ideal for use in a variety of applications. One of the applications is Grid Spring Coupling, which is a popular type of flexible coupling used in various industries, including power generation, oil and gas, chemical processing, and others.

Another application where MW's flexible couplings are suitable is in the Fire Hose Couplings. These couplings are designed to connect hoses used in firefighting operations. The flexible couplings provide a secure and reliable connection and can withstand the high pressure and force of water flowing through the hoses.

In summary, MW's flexible couplings are versatile and reliable industrial flexible connectors that can be used in a variety of applications. Their high speed, corrosion resistance, and high torsional stiffness make them an excellent choice for Grid Spring Coupling and Fire Hose Couplings, among other applications.

FAQ:

Q: What is a flexible coupling?

A: A flexible coupling is a mechanical device that connects two rotating shafts and allows for some degree of misalignment while transmitting torque between them.

Q: What is the maximum torque capacity of MW flexible couplings?

A: The maximum torque capacity of MW flexible couplings depends on the specific model number. Please refer to the product specifications for more information.

Q: Where are MW flexible couplings manufactured?

A: MW flexible couplings are manufactured in China.

Q: What are the benefits of using MW flexible couplings?

A: MW flexible couplings can absorb shock and vibration, reduce noise, compensate for misalignment, and protect machinery from damage, among other benefits.

Q: How do I choose the right MW flexible coupling for my application?

A: The right MW flexible coupling for your application depends on factors such as the type of machinery, the required torque capacity, and the degree of misalignment. Please consult the product specifications or contact us for assistance.

![]()

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200