|

|

|

|

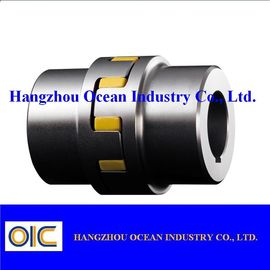

Flange Couplings with Vibration Damping for High Speed Applications

| Vibration Damping: | Yes | Certifications: | ISO 9001, CE |

|---|---|---|---|

| Connection Type: | Flange | Misalignment Capacity: | ±3° |

| Color: | Silver | Application: | Industrial Machinery |

| Max Torque: | 500 Nm | Max Speed: | 10,000 RPM |

Product Description:

Our Flexible Couplings offer high torsional stiffness, which ensures that they can transmit high torque loads with minimal deflection. They have a maximum torque capacity of 500 Nm, which makes them suitable for use in heavy-duty applications.

Our Flexible Couplings have undergone rigorous testing and have received certifications such as ISO 9001 and CE. These certifications assure you that our couplings are manufactured to the highest quality standards and meet all relevant safety requirements.

The stainless steel material used in our Flexible Couplings provides excellent resistance to corrosion, ensuring that they remain reliable and long-lasting. The silver color of the couplings gives them a sleek and professional look, making them suitable for various industrial applications.

Features:

- Product Name: Flexible Couplings

- Size: Various Sizes Available

- Color: Silver

- Application: Industrial Machinery

- Vibration Damping: Yes

- Corrosion Resistance: High

- Types:

- Drum Gear Coupling

- Flexible

- Ball Joint Coupling

Technical Parameters:

| Material | Stainless Steel |

| Misalignment Capacity | ±3° |

| Installation Method | Bolt-on |

| Color | Silver |

| Type | Flexible |

| Max Speed | 10,000 RPM |

| Connection Type | Flange |

| Temperature Range | Up To 200°C |

| Size | Various Sizes Available |

| Vibration Damping | Yes |

Applications:

The MW Flexible Couplings come in two types: Casing Couplings and Grid Spring Coupling. The Casing Coupling is preferred for use in machines that require high torque transmission. It is mainly used in centrifugal pumps, compressors, and turbines. On the other hand, the Grid Spring Coupling is perfect for use in machines that need high-speed transmission. It is widely used in generators, blowers, and fans.

The MW Flexible Coupling Parts can handle a misalignment capacity of up to ±3°. This feature helps to protect machines from damage caused by misaligned shafts. The MW Flexible Couplings come in a silver color, which gives them a sleek and modern look.

The MW Flexible Couplings are used in various applications and scenarios. They are commonly used in industrial machinery, such as pumps, compressors, generators, and turbines. They are also used in the automotive industry, for example, in the drivetrain of vehicles. Other scenarios where MW Flexible Couplings are used include marine and aerospace applications.

In conclusion, the MW Flexible Couplings are high-quality components that are essential for connecting the shafts of two different machines in a power transmission system. Their high corrosion resistance, connection type, vibration damping, misalignment capacity, and silver color make them ideal for various applications and scenarios. They are available in two types: Casing Coupling and Grid Spring Coupling, and are perfect for use in industrial machinery, automotive, marine, and aerospace applications.

FAQ:

Q: What materials are MW flexible couplings made of?

A: MW flexible couplings are made of high-quality materials such as stainless steel, aluminum, and polyurethane.

Q: What is the maximum torque capacity of MW flexible couplings?A: The maximum torque capacity of MW flexible couplings varies depending on the specific model and size, but ranges from 5 Nm to 5000 Nm.

Q: Where are MW flexible couplings manufactured?A: MW flexible couplings are manufactured in China, where the company's headquarters and production facilities are located.

Q: What are the main benefits of using MW flexible couplings?A: MW flexible couplings are designed to provide reliable power transmission while minimizing vibration and noise. They also help to extend the lifespan of connected equipment by reducing stress on the shafts and bearings.

![]()

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200