|

|

|

|

10 Mm Keyway Drive Shaft Welder for 60 Mm Splined End

|

| Splined End Diameter: | 60 Mm | Weight: | 10 Kg |

|---|---|---|---|

| Material: | Steel | Keyway Size: | 10 Mm |

| Flange Thickness: | 20 Mm | Length: | 1.5 Meters |

| Maximum Torque: | 500 Nm | Certifications: | ISO 9001 |

Product Description:

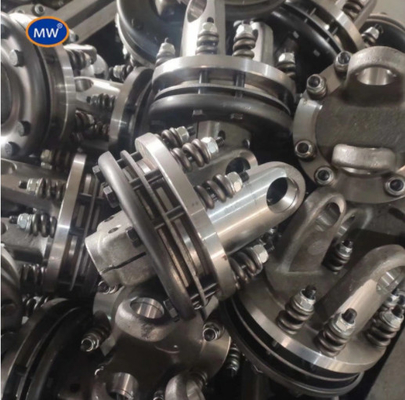

Our PTO Drive Shafts come with a splined end size of 20 teeth, making them ideal for heavy-duty applications that require a high torque transfer. With a splined end diameter of 60 mm, you can be sure that our drive shafts can handle rigorous use and provide long-lasting performance.

Our PTO Drive Shafts are made from high-quality materials, ensuring that they can withstand tough working conditions without compromising on performance. Weighing in at 10 kg, our drive shafts are lightweight yet sturdy, making them easy to install and use.

Measuring 1.5 meters in length, our PTO Drive Shafts are suitable for various applications that require a long reach. Whether you need to transfer power over a long distance or require a drive shaft that can handle flexible movements, our PTO Drive Shafts are the perfect solution.

Our PTO Drive Shafts are certified to ISO 9001 standards, ensuring that they are manufactured to the highest quality and performance standards. You can be confident that our drive shafts will meet your requirements and provide reliable and efficient power transfer for your equipment.

Features:

- Product Name: PTO Drive Shafts

- Shaft Diameter: 50 Mm

- Flange Thickness: 20 Mm

- Weight: 10 Kg

- Maximum Torque: 500 Nm

- Flange Diameter: 100 Mm

- Useful for Flex Shaft Machines, Drive Shaft, and Excavator Shaft

Technical Parameters:

| Splined End Size | 20 Teeth |

| Splined End Length | 50 Mm |

| Length | 1.5 Meters |

| Power Source | Pto Shaft Tube |

| Flange Diameter | 100 Mm |

| Splined End Diameter | 60 Mm |

| Weight | 10 Kg |

| Certifications | ISO 9001 |

| Material | Steel |

| Maximum Torque | 500 Nm |

Applications:

One of the most common applications for the MW PTO Drive Shaft is in Excavator Drive Motors. With a long length of 1.5 meters, this PTO Drive Shaft is perfect for connecting the power source to the excavator drive motor to power up the machine. The strong and sturdy design of the MW PTO Drive Shaft ensures that it can handle the heavy loads and stresses that come with excavating jobs.

Another popular application for the MW PTO Drive Shaft is in Axle Shaft Forgings. The strong and durable design of the PTO Drive Shaft means that it can handle the high torque and power required to drive the axle shaft. This makes the MW PTO Drive Shaft a great choice for industries such as automotive manufacturing and heavy machinery production.

The MW PTO Drive Shaft is also a great choice for powering up Hollow Shaft Motors. The overload protection safety feature ensures that the motor is protected from any damage due to excessive loads or stresses. With the strong and sturdy design of the MW PTO Drive Shaft, you can be sure that your Hollow Shaft Motor will be powered up and running smoothly.

Overall, the MW PTO Drive Shaft is a reliable and high-quality product that can be used in a variety of applications and scenarios. Whether you need to power up an Excavator Drive Motor, Axle Shaft Forging, or Hollow Shaft Motor, the MW PTO Drive Shaft is the perfect choice for the job.

FAQ:

Q: What is a PTO drive shaft?

A: A PTO drive shaft is a mechanical device used to transfer power from a power source, such as a tractor, to a powered implement, such as a mower or baler. It consists of a shaft with universal joints at either end and a telescoping tube to allow for length adjustments.

Q: What is the brand name of the PTO drive shaft?

A: The brand name of the PTO drive shaft is MW.

Q: Where is the PTO drive shaft manufactured?

A: The PTO drive shaft is manufactured in China.

Q: Is the PTO drive shaft compatible with all tractors and implements?

A: The PTO drive shaft is designed to be compatible with most tractors and implements, but it is important to check compatibility before purchasing.

Q: Does the PTO drive shaft come with any warranty?

A: We cannot provide warranty information without knowing the specific model number of the PTO drive shaft. Please refer to the product manual or contact the manufacturer for warranty information.

![]()

pto shaft,

tractor pto shaft

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Power Transmission PTO Drive Shafts For Rotary Tiller , power take off shaft

-

Agricultural Tractor PTO Drive Shafts replacement / custom made drive shafts

-

Professiona Farm Cardan PTO Drive Shafts with Overruning Clutch

-

Custom Planter Machine PTO Drive Shafts Ratchet Torque Limiter driving shaft

-

Auto parts flexible drive shaft PTO / Cardan Shaft for Agriculture Rotavator

-

4x4 Power Take off PTO Drive Shafts Shear Bolt Torque Limiter