|

|

|

|

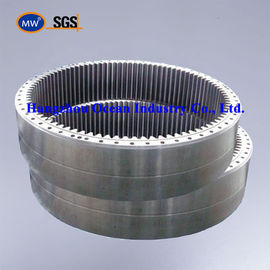

Right Hand Medium Carbon Steel Gearbox Gears with CNC Cutting Accuracy and Carburized Surface

| Size: | Various Sizes Available | Direction: | Right Hand |

|---|---|---|---|

| Hardness: | HRC 45-55 | Module: | 1-10 |

| Tolerance: | 0.01-0.05mm Or Customized | Processing: | CNC Machining |

| Heat Treatment: | Carburizing And Quenching | Application: | Industrial Machinery |

Product Description:

This product is ideal for use in gear box assembly and other applications where precision is of utmost importance. With tolerance levels of 0.01-0.05mm or customized according to customer requirements, the Gears and Pinions product ensures that every gear is machined to exact specifications, resulting in a smooth and efficient operation.

The Gears and Pinions product comes in various sizes to suit different needs and applications. Whether you need small gears for compact machinery or larger gears for heavy-duty applications, this product can provide the right size and fit.

With its high level of accuracy and compatibility with various gear systems, the Gears and Pinions product is an excellent choice for anyone looking for a high-precision gear solution. Its heat treatment processes ensure that it can withstand the rigors of industrial use, while its customizable tolerance levels ensure that it meets your specific requirements.

In summary, the Gears and Pinions product is a reliable and durable solution for industrial machinery that requires high-precision gears. Its compatibility with various gear systems, heat treatment processes, and customizable tolerance levels make it an ideal choice for gear box assembly and other applications where precision is critical.

Features:

- Product Name: Gears and Pinions

- Surface Finish: Ground

- Processing: CNC Machining

- Tolerance: 0.01-0.05mm Or Customized

- Application: Industrial Machinery

- Size: Various Sizes Available

- Keyword: Gear Shafts, Gear Box Components, Gears and Shafts

Technical Parameters:

| Tolerance | 0.01-0.05mm Or Customized |

| Compatibility | Can Be Used With Various Gear Systems |

| Pitch | Standard |

| Module | 1-10 |

| Tooth Profile | Helical Gear |

| Heat Treatment | Carburizing And Quenching |

| Load Capacity | High |

| Material | Steel |

| Processing | CNC Machining |

| Application | Industrial Machinery |

Applications:

These products are manufactured in China using high-quality steel material with a hardness range of HRC 45-55, which ensures they can withstand extreme conditions and provide long-lasting performance.

The gears and pinions are designed for use in a variety of machines and equipment that require precise rotational motion, including automotive, aerospace, industrial machinery, and marine equipment.

The CNC machining process used in manufacturing these gears and pinions ensures that they have a standard pitch and are accurate to the smallest detail, making them highly effective in their application.

The ground surface finish on the gears and pinions further enhances their performance by reducing friction and wear during operation.

The MW Gears and Pinions are particularly suitable for use in gear shafts, where they play a crucial role in transmitting power and torque between different components of the machine.

They are also ideal for use in gear molds where they help to create precise and accurate gear teeth that can withstand high loads and extreme operating conditions.

Whether you need gears and pinions for high-speed applications or for heavy-duty machinery, the MW brand has got you covered.

FAQ:

Q: What is MW Gears and Pinions?

A: MW Gears and Pinions are high-quality mechanical components used to transfer motion and power between rotating shafts.

Q: What material are MW Gears and Pinions made of?

A: MW Gears and Pinions are made of high-strength steel materials to ensure durability and reliability.

Q: What is the manufacturing standard of MW Gears and Pinions?

A: MW Gears and Pinions are manufactured based on the highest international quality standards to ensure consistent quality and performance.

Q: What are the applications of MW Gears and Pinions?

A: MW Gears and Pinions are widely used in various industrial applications, including automotive, aerospace, construction, and marine industries, among others.

Q: Where are MW Gears and Pinions manufactured?

A: MW Gears and Pinions are manufactured in China, ensuring the highest quality and competitive pricing.

![]()

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

With Teeth Hardened Carbon Steel Crush 1.75 Gears And Pinions

-

Helical Spur Bevel JIS Class 0 Crown Wheel Pinion

-

Planetary Helical DIN Class 4 Gears And Pinions

-

Transmission Harden Steel EX60-5 Ring And Pinion Gears

-

Speed Reducer Bronze Steel C45 Worm Wheel Gear

-

Auto Parts Left Hand 1.25 Crown Wheel And Pinion Gear