|

|

|

|

- I'm Online Chat Now

1000 Nm Torque Capacity Rigid Couplings Bolted Connection Max Operating Pressure 10 Bar Durable Design

| Bore Diameter: | 25 Mm | Max Operating Pressure: | 10 Bar |

|---|---|---|---|

| Torque Capacity: | 1000 Nm | Surface Treatment: | Zinc Plated |

| Temperature Range: | 0-100 Degrees Celsius | Shaft Diameter: | 25 Mm |

| Weight: | 0.5 Kg | Size: | 1 Inch |

Product Description:

Rigid couplings are essential components in industrial machinery applications, providing a reliable connection between two shafts and ensuring efficient power transmission. Among the different types of rigid couplings available in the market, the Flanged Rigid Coupling stands out as a robust and versatile option suitable for various industrial settings.

The Flanged Rigid Coupling is designed to provide a secure and precise connection between shafts, ensuring minimal backlash and accurate torque transmission. Made from high-quality steel, this type of coupling offers exceptional strength and durability, making it ideal for heavy-duty applications in industrial machinery.

With a maximum operating pressure of 10 Bar, the Flanged Rigid Coupling is capable of handling high-pressure conditions, making it a reliable choice for demanding industrial environments. Whether used in conveyor systems, pumps, or other machinery, this coupling delivers consistent performance and ensures smooth operation.

One of the key advantages of the Flanged Rigid Coupling is its surface treatment with zinc plating. This surface treatment provides enhanced corrosion resistance, protecting the coupling from rust and other forms of degradation. As a result, the coupling maintains its structural integrity and performance over time, ensuring long-term reliability in industrial applications.

When it comes to connecting shafts in industrial machinery, the Flanged Rigid Coupling offers a secure and precise solution. Whether used in combination with a Flexible Jaw Coupling or as part of a Flexible Rigid PCB system, this coupling provides a stable connection that minimizes misalignment and vibration, improving overall system efficiency.

Manufactured to high standards and with a focus on quality and performance, the Flanged Rigid Coupling is a trusted choice for engineers and maintenance professionals in various industries. Its robust construction, reliable performance, and compatibility with different types of shafts make it a versatile and cost-effective solution for power transmission applications.

In summary, the Flanged Rigid Coupling is a durable and efficient component that plays a crucial role in industrial machinery applications. With its steel construction, zinc plating surface treatment, and ability to withstand high operating pressures, this coupling offers the reliability and performance needed for demanding industrial environments. Whether used in combination with a Flexible Jaw Coupling, a Flexible Rigid PCB, or as a standalone component, the Flanged Rigid Coupling delivers consistent results and ensures smooth operation of machinery.

Features:

- Product Name: Rigid Couplings

- Material: Steel

- Temperature Range: 0-100 Degrees Celsius

- Shaft Misalignment: 0.2 Degrees

- Application: Industrial Machinery

- Keyway Size: 6 mm

Technical Parameters:

| Max Operating Pressure | 10 Bar |

| Weight | 0.5 Kg |

| Temperature Range | 0-100 Degrees Celsius |

| Type | Flanged |

| Keyway Size | 6 Mm |

| Torque Capacity | 1000 Nm |

| Material | Steel |

| Application | Industrial Machinery |

| Connection Type | Bolted |

| Surface Treatment | Zinc Plated |

Applications:

The MW Rigid Couplings are versatile components suitable for a wide range of applications due to their durable construction and reliable performance. Made in CHINA, these rigid couplings are specifically designed for shafts with a diameter of 25 mm, offering a secure and stable connection between shafts. The zinc-plated surface treatment not only provides corrosion resistance but also enhances the overall durability of the coupling.

With a torque capacity of 1000 Nm, the MW Rigid Couplings are ideal for scenarios where a high level of torque transmission is required. Whether used in industrial machinery, conveyor systems, or power transmission equipment, these rigid couplings excel in providing a strong and rigid connection between shafts, ensuring efficient power transmission.

Moreover, the temperature range of 0-100 degrees Celsius makes these rigid couplings suitable for diverse operating environments, from standard room temperature settings to applications involving moderate heat exposure. The lightweight design, weighing only 0.5 kg, adds to the convenience of installation and maintenance.

Product Application Occasions and Scenarios:

- Flange Rigid Coupling for precision machinery: The MW Rigid Couplings are perfect for precision machinery applications where accurate shaft alignment is crucial. The flange design ensures a secure connection, making these couplings ideal for use in CNC machines, robotics, and other precision equipment.

- Industrial automation systems: In industrial automation systems where reliability and durability are key, the MW Rigid Couplings offer a dependable solution. Whether used in material handling systems, packaging machinery, or assembly lines, these couplings provide the rigidity needed for smooth operation.

- Flexible Metal Coupling for machinery with misalignment: Despite being rigid in nature, the MW Rigid Couplings can also accommodate slight misalignments thanks to their flexible metal construction. This feature makes them suitable for use in machinery where minor shaft misalignments may occur, such as pumps, compressors, and fans.

Customization:

Customize your Rigid Couplings with our Product Customization Services from MW. Tailor your couplings to meet your specific requirements. Our couplings are made in CHINA and come in a 1 Inch size with a 25mm Shaft Diameter. Constructed from high-quality Steel, these couplings can withstand a Max Operating Pressure of 10 Bar. The connection type is Bolted, ensuring a secure fit for your application.

Support and Services:

Rigid couplings are a type of mechanical coupling used to connect two shafts together in order to transmit power between them. They are designed to provide a rigid connection, ensuring accurate alignment and efficient power transmission between the shafts. Rigid couplings are commonly used in applications where precise shaft alignment is critical and where there is no need for flexibility or angular misalignment compensation.

Product Technical Support and Services for Rigid Couplings may include:

- Technical assistance for selecting the right type and size of rigid coupling for specific applications

- Installation guidance and support to ensure proper assembly and alignment

- Troubleshooting assistance in case of operational issues or failures

- Maintenance recommendations to prolong the service life of the couplings

- Product training for users or maintenance personnel

Packing and Shipping:

Product Packaging:

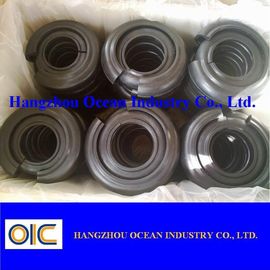

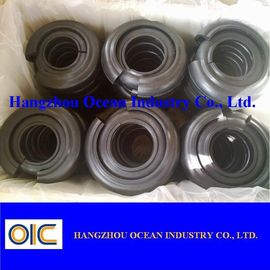

The Rigid Couplings are securely packaged in individual boxes to prevent damage during transportation. Each box is labeled with the product name and specifications for easy identification.

Shipping Information:

Orders for Rigid Couplings are typically shipped within 1-2 business days. We use reputable shipping carriers to ensure prompt delivery to our customers. Shipping costs may vary depending on the destination and selected shipping method.

FAQ:

Q: What is the brand name of the rigid couplings?

A: The brand name of the rigid couplings is MW.

Q: Where is the product manufactured?

A: The rigid couplings are manufactured in China.

Q: Does the product come with a specific model number?

A: No, the rigid couplings do not have a specific model number.

Q: Are the rigid couplings suitable for heavy-duty applications?

A: Yes, these rigid couplings are designed for heavy-duty applications.

Q: Can the rigid couplings be used in high-speed machinery?

A: Yes, these rigid couplings are suitable for use in high-speed machinery.![]()

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Tyre Coupling , type F040 F050 F060 F070 F080 F090 F100 F110

-

Taper Lock Rigid Coupling , type RM12 , RM16 , RM25 , RM30

-

MH Coupling , type MH-55 , MH-65 , MH-80 ,MH-90 ,MH-115

-

NM Coupling , type NM50 ,NM67 , NM82 , NM97 , NM112

-

HRC Coupling , type HRC70 , HRC90 , HRC110 , HRC130

-

Tyre Coupling , typeF120 F140 F160 F180 F200 F220 F250