|

|

|

|

- I'm Online Chat Now

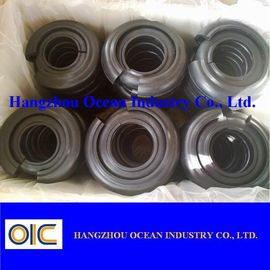

6 Mm Keyway Size Rigid Couplings for 25 Mm Shaft Diameter within Industrial Machinery

| Torque Capacity: | 1000 Nm | Material: | Steel |

|---|---|---|---|

| Shaft Misalignment: | 0.2 Degrees | Connection Type: | Bolted |

| Weight: | 0.5 Kg | Keyway Size: | 6 Mm |

| Surface Treatment: | Zinc Plated | Size: | 1 Inch |

Product Description:

Rigid couplings are an essential component in various mechanical systems where a secure and sturdy connection is required. Among the different types of couplings available in the market, the Rigid Couplings stand out for their robust design and reliable performance. This Product Summary focuses on a specific type of Rigid Couplings with the following key attributes:

Connection Type: Bolted

Keyway Size: 6 mm

Torque Capacity: 1000 Nm

Bore Diameter: 25 mm

Size: 1 inch

Designed for applications that demand a high level of precision and stability, the Rigid Couplings with a bolted connection type offer a secure fit between shafts, ensuring efficient power transmission. With a keyway size of 6 mm, these couplings provide a precise and snug fit, minimizing the risk of misalignment and ensuring smooth operation.

The torque capacity of 1000 Nm makes these Rigid Couplings suitable for medium to heavy-duty applications where reliable torque transmission is crucial. Whether used in industrial machinery, conveyor systems, or other mechanical setups, these couplings can handle significant power requirements with ease.

With a bore diameter of 25 mm and a size of 1 inch, these Rigid Couplings are compatible with standard shaft sizes, offering versatility in various equipment configurations. The precise dimensions ensure a proper fit and alignment, reducing the chances of vibration and wear on the connected components.

When it comes to connecting shafts securely and efficiently, the Rigid Couplings excel in providing a rigid and durable link between rotating elements. Unlike Flexible Diaphragm Couplings or Flexible Shaft Couplings that allow for some degree of misalignment or flexibility, Rigid Couplings, especially those with a bolted connection type, offer a more fixed and stable connection.

These Rigid Couplings are ideal for use in applications where precise alignment and torque transmission are paramount. Whether in the aerospace industry, automotive sector, or manufacturing plants, these couplings play a vital role in maintaining the integrity and efficiency of mechanical systems.

In conclusion, the Rigid Couplings with bolted connection type, 6 mm keyway size, 1000 Nm torque capacity, 25 mm bore diameter, and 1-inch size are a reliable and robust solution for demanding mechanical applications. Their sturdy design, high torque capacity, and precise dimensions make them a go-to choice for engineers and maintenance professionals looking for a secure and durable coupling solution.

Features:

- Product Name: Rigid Couplings

- Temperature Range: 0-100 Degrees Celsius

- Size: 1 Inch

- Shaft Diameter: 25 mm

- Application: Industrial Machinery

- Keyway Size: 6 mm

Technical Parameters:

| Technical Parameter | Value |

|---|---|

| Type | Flanged |

| Material | Steel |

| Weight | 0.5 Kg |

| Shaft Misalignment | 0.2 Degrees |

| Surface Treatment | Zinc Plated |

| Keyway Size | 6 Mm |

| Torque Capacity | 1000 Nm |

| Application | Industrial Machinery |

| Shaft Diameter | 25 Mm |

| Connection Type | Bolted |

Applications:

The MW Rigid Couplings, made in CHINA, are versatile products suitable for a wide range of applications due to their robust nature and reliable performance. With a torque capacity of 1000 Nm, these Flange Rigid Couplings are ideal for connecting shafts in various industrial scenarios.

Product Application Occasions and Scenarios:

1. Industrial Machinery: The MW Rigid Couplings are commonly used in industrial machinery setups where precise shaft alignment and torque transmission are crucial. Their sturdy steel construction ensures long-lasting performance even under heavy loads.

2. Pump Systems: In pump systems where maintaining shaft alignment is essential for efficient operation, the MW Rigid Couplings provide a secure connection between the motor and the pump. This helps prevent misalignment issues and ensures smooth operation.

3. Conveyor Systems: For conveyor systems handling materials in manufacturing plants or warehouses, the MW Rigid Couplings offer a reliable solution for connecting drive shafts. The Flange Rigid Couplings ensure a secure link between different sections of the conveyor, enhancing overall efficiency.

4. Power Transmission Equipment: In power transmission applications where torque transmission is critical, the MW Rigid Couplings play a vital role in connecting various components such as gearboxes, motors, and drive shafts. Their 1 Inch size and ability to withstand up to 10 Bar of operating pressure make them suitable for demanding environments.

5. HVAC Systems: The MW Rigid Couplings are also used in HVAC systems to connect different components like fans, blowers, and motors. Their Flanged design ensures a secure and rigid connection, minimizing vibrations and ensuring smooth operation of the system.

Overall, whether it's in industrial machinery, pump systems, conveyor systems, power transmission equipment, or HVAC systems, the MW Rigid Couplings prove to be reliable and durable components for ensuring proper shaft alignment and torque transmission. Their steel construction and Flange design make them suitable for various applications requiring a secure and rigid coupling solution.

Customization:

Discover our customization services for the MW Rigid Couplings:

Brand Name: MW

Model Number: no

Place of Origin: CHINA

Size: 1 Inch

Material: Steel

Torque Capacity: 1000 Nm

Temperature Range: 0-100 Degrees Celsius

Weight: 0.5 Kg

Support and Services:

Rigid Couplings are designed to connect two shafts together for precise and reliable power transmission. Our Product Technical Support team is available to assist with any questions regarding the installation, maintenance, and troubleshooting of Rigid Couplings. Additionally, we offer a range of services including on-site consultations, training sessions, and custom engineering solutions to meet your specific requirements.

Packing and Shipping:

Product Packaging for Rigid Couplings:

The rigid couplings are securely packaged in a sturdy cardboard box to ensure safe delivery.

Shipping Information:

We offer fast and reliable shipping options for the rigid couplings product. Your order will be carefully packed and dispatched within 1-2 business days of purchase.

FAQ:

Q: What is the brand name of the Rigid Couplings product?

A: The brand name of the Rigid Couplings product is MW.

Q: Where is the Rigid Couplings product manufactured?

A: The Rigid Couplings product is manufactured in CHINA.

Q: Does the Rigid Couplings product come with a model number?

A: No, the Rigid Couplings product does not come with a specific model number.

Q: Are the Rigid Couplings suitable for heavy-duty applications?

A: Yes, the Rigid Couplings are designed to be suitable for heavy-duty applications.

Q: Can the Rigid Couplings be used for both horizontal and vertical shaft alignment?

A: Yes, the Rigid Couplings can be used for both horizontal and vertical shaft alignment.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Tyre Coupling , type F040 F050 F060 F070 F080 F090 F100 F110

-

Taper Lock Rigid Coupling , type RM12 , RM16 , RM25 , RM30

-

MH Coupling , type MH-55 , MH-65 , MH-80 ,MH-90 ,MH-115

-

NM Coupling , type NM50 ,NM67 , NM82 , NM97 , NM112

-

HRC Coupling , type HRC70 , HRC90 , HRC110 , HRC130

-

Tyre Coupling , typeF120 F140 F160 F180 F200 F220 F250