|

|

|

|

- I'm Online Chat Now

20 Mm Flange Thickness PTO Drive Shafts for Power Source Pto Shaft Tube 10 Kg Weight

| Length: | 1.5 Meters | Weight: | 10 Kg |

|---|---|---|---|

| Splined End Size: | 20 Teeth | Flange Diameter: | 100 Mm |

| Keyway Size: | 10 Mm | Safety Features: | Overload Protection |

| Material: | Steel | Shaft Diameter: | 50 Mm |

Product Description:

The PTO Drive Shafts are vital components designed to transmit power from the power source, such as a PTO Shaft Tube, to various agricultural implements. Crafted from durable steel, these drive shafts are known for their exceptional strength and longevity, making them ideal for heavy-duty applications.

With a length of 1.5 meters, these PTO Drive Shafts offer ample reach to connect the power source to the intended machinery efficiently. The generous length ensures flexibility in positioning and easy operation, catering to a wide range of agricultural needs.

Operating at a maximum speed of 1000 RPM, these drive shafts provide reliable power transfer while maintaining smooth and efficient performance. The high maximum speed capability makes them suitable for demanding tasks that require consistent power delivery without compromising on speed.

Equipped with a keyway size of 10mm, these PTO Drive Shafts ensure secure and precise connections between the components, minimizing the risk of slippage or misalignment during operation. The keyway size plays a crucial role in maintaining the integrity and stability of the drive shaft assembly, contributing to its overall efficiency.

Designed to work seamlessly with a Power Take-Off (PTO) Shaft Tube, these drive shafts serve as the essential link between the power source and the agricultural implement, facilitating the transfer of power with precision and control. The compatibility with a PTO Shaft Tube enhances the versatility and functionality of these drive shafts, making them a valuable asset for various agricultural operations.

The PTO Drive Shafts feature a robust construction that can withstand the rigors of continuous use in demanding environments. The steel material used in their fabrication ensures durability and resilience, allowing the drive shafts to perform reliably under challenging conditions without compromising on performance.

Moreover, these drive shafts are equipped with a Drive Shaft Center Bearing, which plays a critical role in supporting and stabilizing the drive shaft assembly. The Drive Shaft Center Bearing helps reduce vibrations and ensures smooth rotation, enhancing the overall efficiency and longevity of the drive shafts.

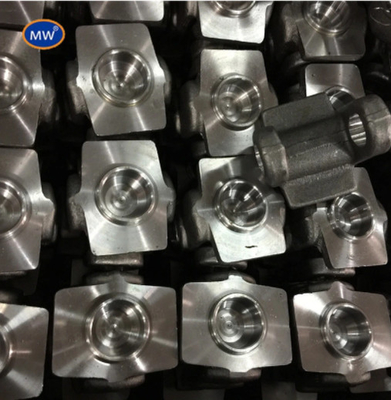

Utilizing advanced forging techniques, these PTO Drive Shafts are precision-engineered to deliver optimal performance and durability. The forging process enhances the structural integrity of the shafts, making them capable of withstanding heavy loads and harsh operating conditions with minimal wear and tear.

In conclusion, the PTO Drive Shafts are reliable, high-performance components that excel in transferring power from a PTO Shaft Tube to agricultural implements with precision and efficiency. Their steel construction, generous length, high-speed capability, keyway size, compatibility with a PTO Shaft Tube, Drive Shaft Center Bearing, and forging shaft design make them an indispensable solution for a wide range of agricultural applications.

Features:

- Product Name: PTO Drive Shafts

- Splined End Diameter: 60 Mm

- Flange Thickness: 20 Mm

- Certifications: ISO 9001

- Power Source: PTO Shaft Tube

- Shaft Diameter: 50 Mm

- Keywords: Extruder Shaft, High Torque Shaft, Drive Axle Shaft

Technical Parameters:

| Certifications | ISO 9001 |

| Power Source | Pto Shaft Tube |

| Weight | 10 Kg |

| Flange Diameter | 100 Mm |

| Material | Steel |

| Keyway Size | 10 Mm |

| Splined End Length | 50 Mm |

| Length | 1.5 Meters |

| Safety Features | Overload Protection |

| Maximum Speed | 1000 Rpm |

Applications:

The MW PTO Drive Shafts are versatile components designed for various product application occasions and scenarios, offering reliable power transmission in a range of industries. With a length of 1.5 meters, these drive shafts are ideal for applications requiring a longer reach, such as agricultural machinery, construction equipment, and industrial machinery.

Featuring a splined end size of 20 teeth and a splined end diameter of 60 mm, the MW PTO Drive Shafts are compatible with a wide range of equipment, including Automotive Drive Shafts, Ceramic Shafts, and CV Drive Shafts. This versatility makes them suitable for use in diverse settings, from automotive workshops to manufacturing facilities.

Manufactured in CHINA, these drive shafts are built to meet high-quality standards and are capable of handling maximum torque of 500 Nm. The inclusion of overload protection ensures the safety of both the equipment and the operator, offering peace of mind during operation.

Whether it's powering a conveyor belt in a warehouse or driving a pump on a farm, the MW PTO Drive Shafts provide efficient and reliable power transfer in a variety of applications. Their durability and performance make them a valuable asset for businesses looking to optimize their machinery's productivity and efficiency.

Customization:

Product Customization Services for the PTO Drive Shafts:

Brand Name: MW

Model Number: no

Place of Origin: CHINA

Shaft Diameter: 50 Mm

Length: 1.5 Meters

Power Source: Pto Shaft Tube

Splined End Diameter: 60 Mm

Keyway Size: 10 Mm

Keywords: Drive Shaft Center Bearing, Drive Shaft Center Bearing, Drive Shaft Center Bearing

Support and Services:

Our Product Technical Support and Services for the PTO Drive Shafts include:

- Expert assistance with installation and troubleshooting.

- Regular maintenance recommendations to ensure optimal performance.

- Access to user manuals and technical documentation.

- Warranty information and support for any product-related issues.

Packing and Shipping:

Product Packaging:

Our PTO Drive Shafts come securely packaged in a sturdy cardboard box to ensure safe delivery. Each shaft is individually wrapped in protective material to prevent any damage during transit.

Shipping:

We offer fast and reliable shipping for all orders of PTO Drive Shafts. Your order will be processed and dispatched within 1-2 business days. We use trusted courier services to deliver your product safely to your doorstep.

FAQ:

Q: What is the brand of the PTO Drive Shafts?

A: The brand of the PTO Drive Shafts is MW.

Q: Where is the PTO Drive Shafts manufactured?

A: The PTO Drive Shafts are manufactured in China.

Q: Does the PTO Drive Shafts come with a model number?

A: No, the PTO Drive Shafts do not come with a specific model number.

Q: Are the PTO Drive Shafts compatible with a wide range of equipment?

A: Yes, the PTO Drive Shafts are designed to be compatible with various types of equipment.

Q: What are the key features of the MW PTO Drive Shafts?

A: The MW PTO Drive Shafts are known for their durability, reliability, and efficient power transfer.

pto shaft,

tractor pto shaft

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Power Transmission PTO Drive Shafts For Rotary Tiller , power take off shaft

-

Agricultural Tractor PTO Drive Shafts replacement / custom made drive shafts

-

Professiona Farm Cardan PTO Drive Shafts with Overruning Clutch

-

Custom Planter Machine PTO Drive Shafts Ratchet Torque Limiter driving shaft

-

Auto parts flexible drive shaft PTO / Cardan Shaft for Agriculture Rotavator

-

4x4 Power Take off PTO Drive Shafts Shear Bolt Torque Limiter