|

|

|

|

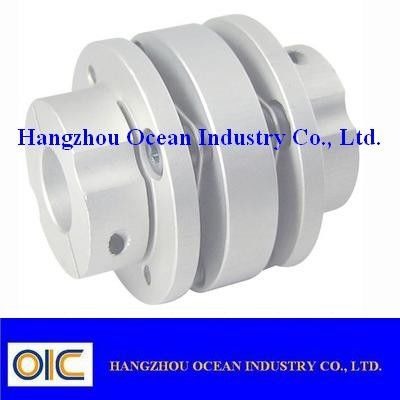

Max Speed up to 000 RPM Flexible Couplings with High Torsional Stiffness and Bolt-on Installation Method

| Misalignment Capacity: | ±3° | Type: | Flexible |

|---|---|---|---|

| Material: | Stainless Steel | Certifications: | ISO 9001, CE |

| Temperature Range: | Up To 200°C | Torsional Stiffness: | High |

| Corrosion Resistance: | High | Application: | Industrial Machinery |

Product Description:

The Flexible Couplings product is a versatile and reliable solution for various industrial applications. With its bolt-on installation method, this coupling is easy to set up and ensures a secure connection between shafts. The flexible nature of this coupling allows for smooth operation even in challenging conditions, making it ideal for a wide range of machinery.

Designed as a flexible gear coupling, this product offers excellent torsional stiffness, providing stability and precision in power transmission. Its high torsional stiffness ensures minimal energy loss and enhanced efficiency, making it a valuable component in demanding industrial environments.

Featuring a connection type of flange, the Flexible Couplings product guarantees a strong and durable link between the connected shafts. The flange connection ensures a secure fit, minimizing the risk of slippage or disconnection during operation. This reliability is crucial for maintaining consistent performance and preventing downtime in industrial processes.

The silver color of this coupling not only adds a sleek and professional look to the machinery but also serves a functional purpose. The silver coating provides corrosion resistance, protecting the coupling from environmental factors and ensuring its longevity and durability.

Whether used in agricultural quick couplings, drum gear couplings, or other industrial applications, the Flexible Couplings product delivers exceptional performance and reliability. Its flexibility, high torsional stiffness, flange connection, and silver color make it a superior choice for demanding machinery and equipment.

Features:

- Product Name: Flexible Couplings

- Corrosion Resistance: High

- Certifications: ISO 9001, CE

- Size: Various Sizes Available

- Torsional Stiffness: High

- Max Torque: 500 Nm

Technical Parameters:

| Type | Flexible |

| Color | Silver |

| Application | Industrial Machinery |

| Max Speed | 10,000 RPM |

| Certifications | ISO 9001, CE |

| Connection Type | Flange |

| Size | Various Sizes Available |

| Temperature Range | Up To 200°C |

| Max Torque | 500 Nm |

| Torsional Stiffness | High |

Applications:

The MW Flexible Couplings are versatile and reliable components suitable for a wide range of industrial applications, thanks to their flexibility and high-quality construction. With its origin in China, this product line includes various types such as Flexible Diaphragm Couplings, Flexible Jaw Couplings, and Aluminum Flexible Couplings.

These couplings are designed to operate efficiently in challenging conditions, with a temperature range of up to 200°C, making them ideal for industries where high temperatures are common. The connection type of these couplings is flange, ensuring a secure and stable connection between components.

With a maximum speed capacity of 10,000 RPM, the MW Flexible Couplings can be used in applications requiring high rotational speeds without compromising performance. The installation method for these couplings is bolt-on, making them easy to set up and integrate into existing systems.

One of the key features of the MW Flexible Couplings is their misalignment capacity of ±3°, allowing for flexibility in alignment and reducing the risk of premature wear on connected equipment. This attribute makes them suitable for situations where slight misalignments are common.

These couplings are commonly used in various industries and scenarios, including but not limited to:

- - Industrial machinery

- - Automation systems

- - Power transmission systems

- - Robotics

- - Packaging equipment

Whether it is for torque transmission, vibration damping, or misalignment compensation, the MW Flexible Couplings provide a reliable solution for demanding applications. Their durability, versatility, and performance make them a preferred choice for engineers and manufacturers looking for high-quality coupling solutions.

Customization:

Product Customization Services for the MW Flexible Couplings:

Brand Name: MW

Model Number: no

Place of Origin: CHINA

Installation Method: Bolt-on

Vibration Damping: Yes

Connection Type: Flange

Misalignment Capacity: ±3°

Application: Industrial Machinery

Keywords: Fire Hose Couplings, Aluminum Flexible Coupling, Drum Gear Coupling

Support and Services:

Our Product Technical Support and Services team for Flexible Couplings is dedicated to providing expert assistance to help you with any questions or issues you may have. Whether you need guidance on product selection, installation instructions, troubleshooting, or maintenance advice, our team is here to support you every step of the way.

We offer a range of services to ensure that your Flexible Couplings perform optimally, including on-site inspections, training sessions, and maintenance contracts. Our goal is to help you maximize the performance and lifespan of your equipment, ultimately saving you time and money in the long run.

Feel free to reach out to our Product Technical Support and Services team for any assistance you may need. We are committed to providing timely and reliable support to help you achieve success with our Flexible Couplings.

Packing and Shipping:

Product Packaging for Flexible Couplings:

Each flexible coupling is carefully wrapped in protective foam and placed in a sturdy cardboard box to prevent any damage during shipping.

Shipping Information:

All orders are processed and shipped within 1-2 business days. We offer standard and expedited shipping options to ensure your flexible couplings reach you in a timely manner. Shipping costs will be calculated at checkout based on your location and preferred shipping method.

FAQ:

Q: What is the brand name of the flexible couplings?

A: The brand name of the flexible couplings is MW.

Q: Do the flexible couplings have a specific model number?

A: No, the flexible couplings do not have a specific model number.

Q: Where are the flexible couplings manufactured?

A: The flexible couplings are manufactured in China.

Q: Are the flexible couplings suitable for high torque applications?

A: Yes, the flexible couplings are designed to handle high torque applications effectively.

Q: Can the flexible couplings accommodate misalignment in machinery?

A: Yes, the flexible couplings are designed to accommodate misalignment in machinery for smoother operation.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200