|

|

|

|

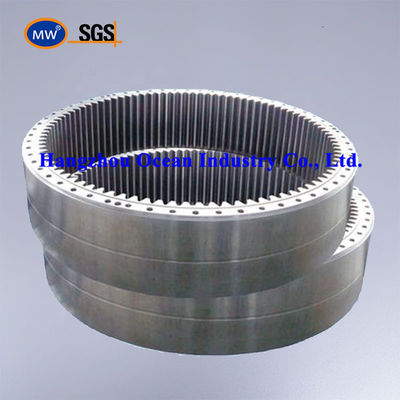

Right Hand Direction Car Gearbox Parts for Enhanced Driving Experience

| Pitch: | Standard | Load Capacity: | High |

|---|---|---|---|

| Material: | Steel | Direction: | Right Hand |

| Module: | 1-10 | Hardness: | HRC 45-55 |

| Surface Finish: | Ground | Tolerance: | 0.01-0.05mm Or Customized |

Product Description:

Gears and pinions are fundamental components in a wide range of mechanical systems, playing a crucial role in power transmission and motion control. Our Gears and Pinions are meticulously engineered to meet the highest standards of performance and durability, making them an ideal choice for various industrial applications. Manufactured from premium steel, these components are designed to deliver exceptional strength and reliability under demanding operating conditions.

One of the standout features of our Gears and Pinions is their high precision. Crafted with advanced manufacturing techniques, these High Precision Gears ensure smooth and accurate meshing, which significantly reduces noise and vibration during operation. This precision is vital for applications such as engine gears, where even minor deviations can lead to performance issues or premature wear. By maintaining tight tolerances, our gears contribute to enhanced efficiency and longevity of the machinery they are incorporated into.

The Direction of the gears is specifically designed as Right Hand, which is essential for compatibility with various mechanical assemblies. Right Hand gears are commonly used in numerous gear trains and power transmission systems, providing reliable rotational direction and torque transfer. This directional specification ensures that the gears fit perfectly into existing setups or new designs requiring right-hand orientation, facilitating seamless integration and optimal performance.

Material selection plays a pivotal role in the durability and functionality of gears and pinions. Our products are made from high-grade steel, chosen for its excellent mechanical properties, including tensile strength, toughness, and wear resistance. This robust material foundation allows the gears to withstand high loads and harsh operating environments without compromising structural integrity. Steel also offers excellent machinability, enabling the production of complex gear shapes and fine details necessary for precision gearing.

To further enhance the durability and surface hardness, the gears undergo a specialized Heat Treatment process involving Carburizing and Quenching. Carburizing enriches the surface layer of the steel with carbon, creating a hard, wear-resistant exterior while maintaining a tougher, more ductile core. This combination of hardness and toughness is crucial for gears subjected to continuous stress and friction. Quenching rapidly cools the gear after carburizing, locking in the hardened surface structure and improving resistance to fatigue and wear. This treatment results in a hardness level ranging between HRC 45-55, striking an optimal balance between hardness and toughness.

The Shape of the gears is round, a classic and widely utilized form that supports smooth rotation and consistent contact between teeth. Round gears are fundamental in transmitting power efficiently and are compatible with a variety of gear molds used in manufacturing. The round shape also facilitates easier alignment and assembly within mechanical systems, ensuring reliable operation and reduced maintenance requirements.

These Gears and Pinions are especially suited for applications involving Engine Gears, where precision, durability, and reliability are paramount. Engine gears must endure high rotational speeds and torque loads while maintaining stable performance over extended periods. Our high precision gears meet these demands by combining superior material quality, advanced heat treatment, and exacting manufacturing standards.

Moreover, our expertise extends to the development and utilization of specialized Gear Molds that aid in producing gears with consistent quality and intricate designs. These molds are integral to the manufacturing process, enabling the creation of gears that adhere to stringent specifications and performance criteria. By leveraging state-of-the-art gear molds, we ensure that each gear and pinion delivers optimal meshing characteristics, dimensional accuracy, and surface finish.

In summary, our Gears and Pinions offer a comprehensive solution for industries seeking reliable, high-performance gearing components. With attributes such as Right Hand Direction, HRC 45-55 Hardness, premium Steel Material, Carburizing and Quenching Heat Treatment, and a classic Round Shape, these gears are engineered to perform at the highest level. Whether employed in engine gear assemblies or precision machinery, our high precision gears provide the durability, accuracy, and efficiency necessary for superior mechanical operation.

Features:

- Product Name: Gears and Pinions

- Processing: CNC Machining for precision and durability

- Compatibility: Can be used with various gear systems including Gear Box Components and Gear Shafts

- Size: Various sizes available to fit different Gear Mold requirements

- Tooth Profile: Helical gear for smooth and efficient power transmission

- Pitch: Standard pitch ensuring compatibility with industry-standard gear systems

Technical Parameters:

| Direction | Right Hand |

| Material | Steel |

| Compatibility | Can Be Used With Various Gear Systems |

| Tooth Profile | Helical Gear |

| Size | Various Sizes Available |

| Processing | CNC Machining |

| Heat Treatment | Carburizing And Quenching |

| Shape | Round |

| Load Capacity | High |

| Module | 1-10 |

Applications:

The MW Gears and Pinions are precision-engineered components designed to meet the rigorous demands of industrial machinery applications. Manufactured in China using advanced CNC machining processes, these gears and pinions offer exceptional accuracy and durability. The heat treatment process, involving carburizing and quenching, enhances their hardness and wear resistance, making them ideal for heavy-duty performance in various mechanical systems.

One of the primary application occasions for MW Gears and Pinions is within engine gear assemblies. These components play a critical role in the transmission of power and torque, ensuring smooth and efficient operation of engines across multiple industries. The standard pitch design of these gears guarantees compatibility and reliable meshing with other components, maintaining optimal performance under high stress conditions.

In addition to engine gears, MW also specializes in gear shafts that serve as vital elements in the drivetrain of industrial equipment. These shafts are precisely ground to achieve a superior surface finish, reducing friction and enhancing the longevity of the components. MW gear shafts are frequently utilized in applications where precision and durability are paramount, such as heavy machinery, robotics, and automation systems.

Furthermore, MW's expertise extends to producing car gearbox parts, which require stringent quality standards to ensure safety and efficiency in automotive transmissions. The carburizing and quenching treatment applied to these parts not only improves their hardness but also contributes to their resistance against fatigue and wear. This makes them highly reliable for use in car gearboxes where consistent performance and durability are essential.

Overall, the MW Gears and Pinions are suitable for a wide range of industrial machinery scenarios, including manufacturing plants, automotive workshops, and heavy equipment maintenance. Their precision CNC machining, combined with advanced heat treatment and ground surface finish, ensures that these gears and pinions deliver outstanding performance in demanding environments. Whether it’s engine gears, gear shafts, or car gearbox parts, MW products stand out for their quality and reliability, making them a trusted choice for industrial applications worldwide.

Customization:

MW offers customizable Gears and Pinions designed to meet the specific needs of your gear box components. Manufactured in China, these high precision gears feature a round shape and compatibility with various gear systems, ensuring seamless integration into your machinery. With a module range of 1-10 and standard pitch, MW gears provide reliable performance. The tolerance can be precisely controlled between 0.01-0.05mm or tailored to your exact requirements, guaranteeing optimal fit and function for your gear box components.

Support and Services:

Our Gears and Pinions product line is backed by comprehensive technical support and services to ensure optimal performance and longevity. We provide detailed installation guides, maintenance tips, and troubleshooting advice to help you get the most out of your gears and pinions.

Our technical support team is equipped with extensive knowledge in gear design, material selection, and application-specific requirements. They are ready to assist you with product selection, custom solutions, and performance optimization tailored to your needs.

We also offer repair and refurbishment services to extend the life of your gears and pinions, as well as precision manufacturing capabilities for custom specifications. Regular updates on product enhancements and best practices are available to keep your operations running smoothly.

For any technical inquiries or service requests, our support resources are designed to provide timely and effective solutions, ensuring that your mechanical systems operate efficiently and reliably.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

With Teeth Hardened Carbon Steel Crush 1.75 Gears And Pinions

-

Helical Spur Bevel JIS Class 0 Crown Wheel Pinion

-

Planetary Helical DIN Class 4 Gears And Pinions

-

Transmission Harden Steel EX60-5 Ring And Pinion Gears

-

Speed Reducer Bronze Steel C45 Worm Wheel Gear

-

Auto Parts Left Hand 1.25 Crown Wheel And Pinion Gear