|

|

|

|

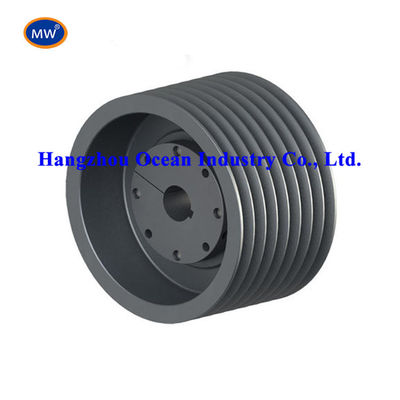

Maximum Load Capacity Depends On Size And Type Belt Pulleys With Black Oxide Finish Engineered For Power Transmission Systems

| Material: | Steel | Manufacturer: | Various Manufacturers Available |

|---|---|---|---|

| Surface Treatment: | Black Oxide, Zinc Plated, Or Custom Coatings | Number Of Grooves: | Single, Double, Or Multi-groove |

| Maximum Load Capacity: | Depends On Size And Type | Type: | V-Belt Pulley |

| Application: | Used In Power Transmission Systems | Process: | Cnc Machining Cnc Turning |

Product Description:

Belt pulleys are essential mechanical components widely used in various industrial and commercial applications to transmit power and motion between shafts through belts. These pulleys play a crucial role in systems involving Chain Pulley Blocks, Elevator Belts, and Belt Jointing Machines, ensuring efficient and reliable operation. Our Belt Pulleys are designed with flexibility and customization in mind, catering to diverse requirements and specifications from different industries.

One of the standout features of our Belt Pulleys is the ability to customize them as per the provided drawings. This customization option allows clients to obtain pulleys tailored exactly to their project needs, ensuring optimal compatibility with existing systems. Whether you require a specific groove profile, diameter, or thickness, our manufacturing partners can produce pulleys that meet your precise specifications. This level of customization is particularly beneficial for applications involving specialized machinery like Belt Jointing Machines, where the accuracy and fit of components are critical.

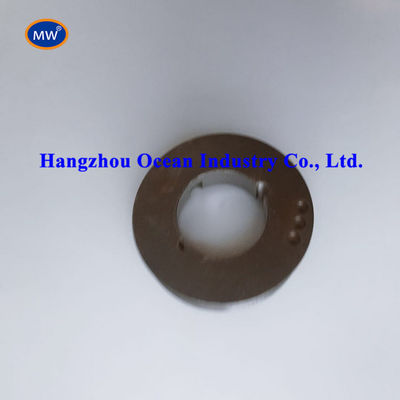

The keyway size of the Belt Pulleys is another important attribute that can be customized. We offer standard keyway sizes that conform to industry norms, but for specialized applications, custom keyway sizes are also available. This flexibility ensures that the pulley fits perfectly onto shafts of various dimensions, providing secure and stable power transmission. Whether the pulley is used in heavy-duty Chain Pulley Blocks or delicate Elevator Belts, the keyway can be tailored to provide the best mechanical fit.

Color options for our Belt Pulleys include natural and black finishes. The natural finish typically refers to the raw metal surface, which can be ideal for applications where aesthetics are secondary to functionality. The black finish usually results from a coating or treatment process that enhances corrosion resistance and durability, making it suitable for harsher environments or outdoor use. Depending on the working conditions and environmental exposure, clients can choose the color that best suits their operational needs and maintenance preferences.

The outside diameter of the Belt Pulleys varies depending on the size and type required. Since the diameter directly affects the belt speed and torque transmission, selecting the correct size is critical to achieving desired performance outcomes. Our product range covers a wide spectrum of diameters to accommodate different belt widths and load requirements. Whether you are working on an Elevator Belt system that demands smooth and quiet operation or a robust Chain Pulley Block designed for heavy lifting, the pulley diameter can be optimized to match the application perfectly.

We collaborate with various manufacturers to provide high-quality Belt Pulleys, ensuring that customers have access to a broad selection of products with different specifications, materials, and production techniques. This network of manufacturers enables us to source pulleys that meet stringent quality standards and deliver reliable performance in demanding industrial environments. Whether you require pulleys made from cast iron, steel, or other materials, the variety available ensures that you can find the right match for your machinery.

In summary, our Belt Pulleys offer a combination of customization, versatility, and quality that makes them ideal for use in systems involving Chain Pulley Blocks, Elevator Belts, and Belt Jointing Machines. With customizable keyway sizes, multiple color options, and a range of outside diameters, these pulleys can be tailored to fit specific applications perfectly. Supported by various reputable manufacturers, our Belt Pulleys provide dependable performance and durability, helping to maintain the efficiency and longevity of your mechanical systems.

Features:

- Product Name: Belt Pulleys

- Keyway Size: Standard or Custom Sizes available

- Bore Type: Taper Bore for secure fit

- Application: Used in power transmission systems including conveyor drum pulley and automotive belt tensioner

- Manufacturing: Produced in our own mould factory ensuring high quality

- Maximum Load Capacity: Depends on size and type of the pulley

- Ideal for conveyor drum pulley and automotive belt tensioner applications

Technical Parameters:

| Keyway Size | Standard Or Custom Sizes |

| Application | Used In Power Transmission Systems including Auto Belt Tensioner, Engine Fan Pulley, Conveyor Belt Press |

| Number Of Grooves | Single, Double, Or Multi-groove |

| Process | CNC Machining, CNC Turning |

| Manufacturer | Various Manufacturers Available |

| Customize | Customize As Drawing |

| Mould | Own Mould Factory |

| Surface Treatment | Black Oxide, Zinc Plated, Or Custom Coatings |

| Outside Diameter | Depends On Size And Type |

| Maximum Speed | Depends On Size And Type |

Applications:

The MW Belt Pulleys, manufactured in China, are essential components widely used in various power transmission systems. Known for their robust construction from high-quality steel, these pulleys are designed to handle varying maximum load capacities and speeds depending on their size and type. Their versatility and durability make them ideal for numerous industrial and mechanical applications.

One of the common application occasions for MW Belt Pulleys is in automotive engines, where the Alternator Belt Pulley plays a critical role. This pulley helps drive the alternator, ensuring the vehicle’s electrical system remains charged and operational. The precision engineering of MW's alternator belt pulleys guarantees smooth and efficient power transmission, contributing to the overall reliability of the engine.

Another typical scenario involves the Crankshaft Pulley, which is integral to the operation of internal combustion engines. MW Crankshaft Pulleys are designed to withstand the high rotational speeds and loads associated with engine operation. They transmit mechanical power from the crankshaft to auxiliary components such as the water pump, power steering pump, and air conditioning compressor, making them indispensable in automotive and industrial machinery applications.

In addition to automotive uses, MW Belt Pulleys are also employed in construction and utility sectors, particularly the Cable Pulling Pulley. This type of pulley is utilized in cable installation and maintenance tasks, where it facilitates the smooth and controlled pulling of cables over long distances or around obstacles. The customizable design options allow these pulleys to be tailored according to specific project drawings, ensuring optimal performance in diverse field conditions.

Thanks to their customizable nature, MW Belt Pulleys can be adapted to meet unique specifications provided in detailed drawings, allowing engineers and designers to specify exact dimensions, load capacities, and material requirements. This flexibility is crucial for applications that demand precise alignment and load handling capabilities.

Overall, MW Belt Pulleys are indispensable in various mechanical and industrial settings, offering reliable power transmission, durability, and adaptability. Whether used as Alternator Belt Pulleys, Crankshaft Pulleys, or Cable Pulling Pulleys, these steel components provide exceptional performance across a wide range of speeds and load conditions, making them a preferred choice for engineers worldwide.

Customization:

MW offers comprehensive product customization services for Belt Pulleys, tailored to meet your specific requirements. Manufactured in China by various trusted manufacturers, our Belt Pulleys are crafted using advanced CNC machining and CNC turning processes to ensure precision and durability. The outside diameter of each pulley depends on the size and type you need, providing flexibility for different applications.

Available in natural and black colors, our Belt Pulleys are produced in our own mould factory, guaranteeing high-quality products with consistent performance. These pulleys are ideal components for Conveyor Drum Pulley systems and essential Belt Conveyor Accessories, designed to enhance the efficiency of Belt Conveyor Machines in various industries.

Choose MW for reliable and customizable Belt Pulleys that perfectly fit your conveyor system needs, supported by expert manufacturing and quality control.

Support and Services:

Our Belt Pulleys are designed to deliver reliable performance and long service life in a variety of industrial applications. For technical support, please ensure you have the product model number, specifications, and details about your application ready when seeking assistance.

We offer comprehensive services including installation guidance, maintenance tips, troubleshooting advice, and replacement part information to help you maximize the efficiency and longevity of your belt pulley system.

For optimal performance, regular inspection and proper alignment of belt pulleys are recommended. Our technical support team can provide detailed instructions and best practices tailored to your specific setup.

Should you encounter any issues or require custom solutions, our experts are available to assist with engineering support and product customization options to meet your unique operational needs.

We are committed to ensuring your satisfaction and the seamless operation of your equipment through dedicated support and service excellence.

Packing and Shipping:

Our belt pulleys are carefully packaged to ensure they arrive in perfect condition. Each pulley is wrapped in protective material to prevent scratches and damage during transit. They are then securely placed in sturdy, reinforced boxes designed to withstand shipping pressures.

For shipping, we partner with reliable carriers to provide timely and safe delivery. Tracking information will be provided once the product is dispatched, allowing you to monitor your shipment until it reaches your doorstep. We also offer various shipping options to meet your needs, including expedited and standard delivery services.

If you have any specific packaging or shipping requirements, please contact our customer service team, and we will do our best to accommodate your requests.

FAQ:

Q1: What brand manufactures the Belt Pulleys?

A1: The Belt Pulleys are manufactured by the brand MW.

Q2: Do the Belt Pulleys have a specific model number?

A2: No, the Belt Pulleys do not have a specific model number.

Q3: Where are the MW Belt Pulleys made?

A3: The MW Belt Pulleys are made in China.

Q4: What materials are used to make MW Belt Pulleys?

A4: MW Belt Pulleys are typically made from high-quality metals such as steel or aluminum to ensure durability and performance.

Q5: Are MW Belt Pulleys compatible with standard belt sizes?

A5: Yes, MW Belt Pulleys are designed to be compatible with standard belt sizes used in various industrial applications.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378