|

|

|

|

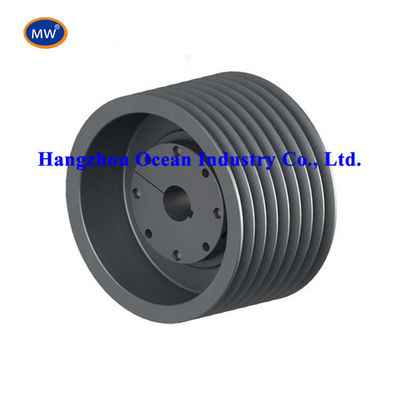

Custom Coatings Belt Pulleys Multi groove Variants Customize As Drawing Suitable For Various Industrial Machinery

| Keyway Size: | Standard Or Custom Sizes | Maximum Speed: | Depends On Size And Type |

|---|---|---|---|

| Process: | Cnc Machining Cnc Turning | Number Of Grooves: | Single, Double, Or Multi-groove |

| Surface Treatment: | Black Oxide, Zinc Plated, Or Custom Coatings | Manufacturer: | Various Manufacturers Available |

| Customize: | Customize As Drawing | Outside Diameter: | Depends On Size And Type |

Product Description:

Belt pulleys are essential mechanical components widely used in various industrial applications to transmit power and motion between shafts. They serve as a critical part of belt-driven systems, ensuring efficient and smooth operation in machinery ranging from simple conveyors to complex automotive engines. Our belt pulleys are designed with versatility and durability in mind, catering to diverse operational needs and environments.

The maximum load capacity of our belt pulleys depends on their size and type, allowing for tailored solutions that meet specific mechanical requirements. Whether you are working on a heavy-duty conveyor system or a precision-driven machine, selecting the appropriate pulley size ensures optimal performance and longevity. The outside diameter of the pulleys also varies according to the size and type, providing flexibility in design and application. This adaptability makes our belt pulleys suitable for a wide range of uses, from lightweight tasks to demanding industrial operations.

Color options for our belt pulleys include natural and black finishes. The natural color typically indicates untreated or minimally processed metal, which is ideal for applications where corrosion resistance is managed through other means or where aesthetic considerations are minimal. The black finish, often achieved through coating or anodizing processes, provides enhanced protection against wear and corrosion, making these pulleys suitable for harsh environments and extended use.

Our belt pulleys come with a variety of groove configurations to accommodate different types of belts and operational needs. Customers can choose from single, double, or multi-groove pulleys, each designed to support specific belt arrangements and improve power transmission efficiency. Single-groove pulleys are typically used for simple belt systems, whereas double and multi-groove pulleys enable the simultaneous operation of multiple belts, increasing load capacity and reducing slippage.

The keyway size of our belt pulleys is available in both standard and custom sizes. This feature allows for precise fitting on shafts of various diameters and ensures secure attachment, minimizing the risk of slippage or misalignment during operation. Custom keyways can be manufactured to meet unique specifications, providing solutions for specialized machinery and applications that require exacting tolerances and configurations.

In industrial settings, belt pulleys are often integrated with specialized equipment such as Belt Jointing Machines, Conveyor Bend Pulleys, and Crankshaft Pulleys. Belt Jointing Machines rely on compatible pulleys to ensure smooth belt splicing and joining processes, improving the overall efficiency and reliability of conveyor systems. Conveyor Bend Pulleys, designed to guide belts around curves and bends, require precise groove configurations and robust construction to maintain tension and alignment under load. Crankshaft Pulleys, commonly found in automotive and mechanical engines, demand high-strength materials and accurate keyway sizing to handle rotational forces and maintain engine performance.

Our belt pulleys are manufactured using high-quality materials and advanced production techniques, ensuring durability, resistance to wear, and consistent performance. Whether you require pulleys for manufacturing lines, automotive repairs, or custom machinery projects, our product range offers the flexibility and reliability needed to meet your demands. With options to customize groove numbers, keyway sizes, and finishes, you can be confident in finding the right pulley to optimize your system’s functionality.

In summary, our belt pulleys provide a comprehensive solution for power transmission in various mechanical applications. Their customizable attributes—including maximum load capacity, outside diameter, color, number of grooves, and keyway size—allow for precise adaptation to specific operational requirements. By incorporating these pulleys into systems involving Belt Jointing Machines, Conveyor Bend Pulleys, or Crankshaft Pulleys, users can achieve enhanced efficiency, durability, and performance, making them indispensable components in modern industrial and mechanical engineering.

Features:

- Product Name: Belt Pulleys

- Application: Used In Power Transmission Systems

- Outside Diameter: Depends On Size And Type

- Color Options: Natural, Black

- Mould: Own Mould Factory

- Manufacturer: Various Manufacturers Available

- Includes Types Such As Belt Tensioner Pulley and Drive Belt Pulley

- Suitable For Automotive Belt Tensioner Applications

Technical Parameters:

| Keyway Size | Standard Or Custom Sizes |

| Material | Steel |

| Number Of Grooves | Single, Double, Or Multi-groove |

| Customize | Customize As Drawing |

| Outside Diameter | Depends On Size And Type |

| Manufacturer | Various Manufacturers Available |

| Bore | Taper Bore |

| Type | V-Belt Pulley |

| Maximum Load Capacity | Depends On Size And Type |

| Maximum Speed | Depends On Size And Type |

Applications:

The MW brand Belt Pulleys, manufactured in China, are essential components widely used in power transmission systems. These pulleys are designed to transfer mechanical power efficiently and reliably across various industrial applications. Made from high-quality steel, MW Belt Pulleys undergo precise CNC machining and CNC turning processes to ensure accuracy and durability. Their surface treatment options, including black oxide, zinc plating, or custom coatings, provide enhanced resistance to corrosion and wear, extending the product’s service life in demanding environments.

One of the primary application occasions for MW Belt Pulleys is in belt conveyor accessories. These pulleys serve as critical elements in conveyor systems, facilitating the smooth movement of materials along production lines. Whether in manufacturing plants, packaging facilities, or distribution centers, MW Belt Pulleys help maintain consistent conveyor belt tension and alignment, preventing slippage and ensuring efficient power transmission.

Another common scenario involves their use in conveyor belt presses, where the pulleys contribute to the pressing and moving of materials under controlled pressure. The versatility of MW Belt Pulleys allows them to be customized with different outside diameters depending on the size and type required for specific machinery. This adaptability makes them suitable for both light and heavy-duty conveyor operations.

Additionally, MW Conveyor Drive Pulleys play a crucial role in driving conveyor belts by transmitting power from the motor to the belt. Their robust steel construction and precision engineering make them ideal for handling high torque and load requirements. These pulleys ensure smooth and continuous belt motion, which is vital for maintaining operational efficiency in industries such as mining, agriculture, logistics, and food processing.

Overall, MW Belt Pulleys are indispensable components in power transmission systems, offering reliable performance across diverse industrial applications. Their combination of superior material quality, advanced CNC processing, and protective surface treatments makes them a preferred choice for enhancing the functionality and longevity of conveyor belt systems worldwide.

Customization:

MW brand V-Belt Pulleys are expertly crafted in China using high-quality steel to ensure durability and reliability in power transmission systems. Our belt pulleys undergo precise CNC machining and CNC turning processes to meet exact specifications. Surface treatments such as black oxide, zinc plating, or custom coatings are available to enhance corrosion resistance and extend product life. These pulleys are ideal for applications including conveyor belt systems and engine fan pulley mechanisms, providing efficient and reliable performance in various industrial settings. Customize your conveyor belt pulley with MW to achieve optimal functionality tailored to your needs.

Support and Services:

Our Belt Pulleys are designed for high performance and durability in a variety of industrial applications. For technical support, please ensure you have the following information ready: pulley model number, dimensions, material specifications, and application details. Our support team can assist with installation guidance, maintenance tips, troubleshooting common issues, and compatibility inquiries.

We offer comprehensive services including custom pulley design, precision machining, and balancing to meet your specific requirements. Replacement parts and upgrades are also available to maximize the lifespan and efficiency of your pulley systems.

For optimal performance, it is recommended to regularly inspect the belt pulleys for wear, alignment, and proper tension. Proper lubrication and cleaning will also extend the service life of the pulleys. Should you encounter any issues or need expert advice, our technical support team is ready to assist you with prompt and professional service.

Packing and Shipping:

Our Belt Pulleys are carefully packaged to ensure they arrive in perfect condition. Each pulley is securely wrapped with protective materials to prevent any damage during transit. The pulleys are then placed in sturdy, reinforced boxes that provide excellent cushioning and support.

For shipping, we use reliable carriers and offer various shipping options to meet your needs. All orders are tracked and handled with care to ensure timely and safe delivery. Whether you need a single pulley or bulk quantities, we guarantee secure packaging and efficient shipping service.

FAQ:

Q1: What brand manufactures these belt pulleys?

A1: These belt pulleys are manufactured by the brand MW.

Q2: What is the model number of these belt pulleys?

A2: These belt pulleys do not have a specific model number assigned.

Q3: Where are MW belt pulleys made?

A3: MW belt pulleys are made in China.

Q4: What materials are used to make MW belt pulleys?

A4: MW belt pulleys are typically made from high-quality metals such as aluminum or steel to ensure durability and performance.

Q5: Can MW belt pulleys be used with different types of belts?

A5: Yes, MW belt pulleys are compatible with various types of belts including V-belts and timing belts, depending on the pulley design.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378