|

|

|

|

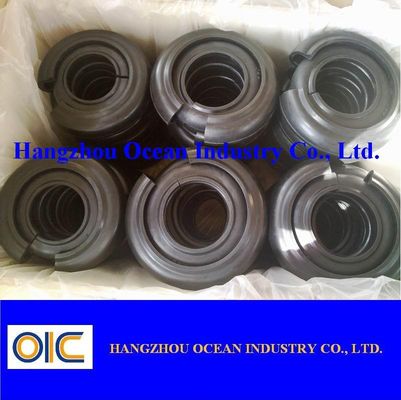

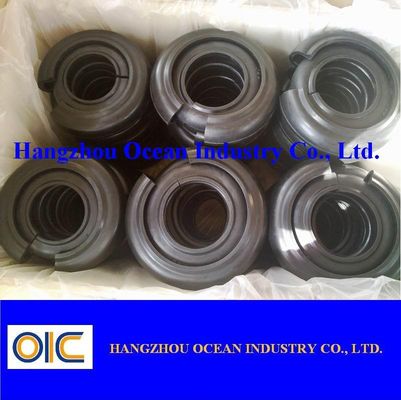

6 Mm Keyway Size Rigid Couplings Bolted Connection Type Ideal for Temperature Range 0 to 100 Degrees Celsius Heavy Duty Equipment

| Torque Capacity: | 1000 Nm | Material: | Steel |

|---|---|---|---|

| Surface Treatment: | Zinc Plated | Shaft Diameter: | 25 Mm |

| Keyway Size: | 6 Mm | Application: | Industrial Machinery |

| Temperature Range: | 0-100 Degrees Celsius | Connection Type: | Bolted |

Product Description:

The Flange Rigid Coupling is an essential component designed specifically for industrial machinery applications, providing a robust and reliable solution for connecting two shafts securely. This type of coupling is engineered to deliver precise alignment and efficient power transmission between rotating shafts, ensuring optimal performance and longevity of the machinery it serves. With a bore diameter of 25 mm, this coupling is perfectly suited for a wide range of industrial equipment where exact shaft connection and minimal movement are critical.

One of the defining features of this Flanged Rigid Coupling is its flanged design, which facilitates easy installation and maintenance. The flanged ends allow for secure bolting between shafts, creating a solid connection that minimizes backlash and eliminates any play between the coupled shafts. This solid connection is particularly beneficial in applications where high torque and rigid shaft alignment are required, making it an ideal choice for heavy-duty industrial machinery where precision and durability are paramount.

The temperature range of this coupling spans from 0 to 100 degrees Celsius, making it versatile enough to operate efficiently in various industrial environments. Whether the machinery is running in standard ambient conditions or slightly elevated temperatures, this coupling maintains its structural integrity and performance without degradation. This temperature tolerance ensures that the coupling can be relied upon in diverse manufacturing and processing settings, from assembly lines to heavy manufacturing plants.

While the primary function of the Flange Rigid Coupling is to provide a firm connection, it also accommodates a slight shaft misalignment of up to 0.2 degrees. This small allowance helps reduce stress on the shafts and other connected components, preventing premature wear and potential damage. Although rigid couplings typically do not offer the flexibility found in other coupling types, this minor tolerance is critical for maintaining system reliability and extending the service life of industrial machinery.

In contrast to flexible coupling types such as the Flexible Diaphragm Coupling, which is designed to accommodate greater misalignment and absorb vibrations, the Flange Rigid Coupling focuses on maintaining a fixed shaft alignment. This distinction makes it an excellent choice when precise shaft positioning is necessary, and any relative movement between shafts must be minimized. However, in systems where vibration damping and flexibility are needed, a Flexible Diaphragm Coupling might be preferred, highlighting the importance of selecting the appropriate coupling based on specific application requirements.

The Coupling Sleeve is another important component often used alongside these couplings. It acts as a protective and connecting element, ensuring that torque is transmitted smoothly while protecting the shafts from wear and damage. In the context of Flanged Rigid Couplings, the coupling sleeve helps to maintain alignment and structural integrity, contributing to the overall durability and efficiency of the machinery.

Overall, the Flange Rigid Coupling with a 25 mm bore diameter is a highly reliable and sturdy solution for industrial machinery applications. Its flanged design provides ease of installation and a secure connection, while its capability to handle temperatures up to 100 degrees Celsius and slight shaft misalignment of 0.2 degrees ensures adaptability and longevity in demanding operational environments. When combined with complementary components like the coupling sleeve, this coupling type forms a critical part of the mechanical drive system, ensuring smooth, efficient, and precise power transmission.

Choosing the right coupling is essential for optimizing machinery performance and minimizing downtime. The Flanged Rigid Coupling stands out as a dependable option for applications requiring fixed shaft alignment and robust torque transmission. While flexible options like the Flexible Diaphragm Coupling offer advantages in vibration absorption and misalignment accommodation, the rigidity and strength of the Flanged Rigid Coupling make it indispensable for many industrial setups. By understanding the specific needs of the machinery and the operational conditions, engineers and maintenance professionals can make informed decisions to enhance system reliability and productivity.

Features:

- Product Name: Rigid Couplings

- Size: 1 Inch

- Surface Treatment: Zinc Plated for enhanced durability

- Temperature Range: Operates efficiently between 0-100 Degrees Celsius

- Weight: 0.5 Kg, lightweight and easy to install

- Bore Diameter: 25 Mm, suitable for various shaft sizes

- Compatible with Flexible Coupling Parts for versatile applications

- Ideal for use in Flex Rigid PCB assemblies

- Includes Grooved Couplings design for secure and reliable connection

Technical Parameters:

| Weight | 0.5 Kg |

| Max Operating Pressure | 10 Bar |

| Shaft Diameter | 25 Mm |

| Torque Capacity | 1000 Nm |

| Size | 1 Inch |

| Keyway Size | 6 Mm |

| Connection Type | Bolted |

| Application | Industrial Machinery |

| Shaft Misalignment | 0.2 Degrees |

| Bore Diameter | 25 Mm |

Applications:

The MW Rigid Couplings, manufactured in China, are precision-engineered components designed to connect shafts with a size of 1 inch while accommodating a shaft misalignment of up to 0.2 degrees. Made from high-quality steel and featuring a zinc-plated surface treatment, these flanged rigid couplings offer durability, corrosion resistance, and reliable performance in various industrial applications. Their robust construction ensures efficient torque transmission without backlash, making them ideal for scenarios where precise shaft alignment is critical.

One of the primary application occasions for MW Rigid Couplings is in machinery where stable and accurate shaft connection is essential. These couplings are widely used in manufacturing equipment, conveyor systems, and automation assemblies where slight misalignment must be managed without compromising mechanical integrity. Their flanged design simplifies installation and maintenance, making them suitable for repetitive assembly and disassembly operations.

In scenarios involving motor-driven systems, MW Rigid Couplings provide a secure connection between the motor shaft and the driven equipment, reducing vibration and wear. They are often utilized alongside other coupling types such as Flex Rigid PCB, Aluminum Flexible Coupling, and Flexible Rubber Coupling to optimize system flexibility and performance. While flexible couplings like the Aluminum Flexible Coupling or Flexible Rubber Coupling absorb shocks and accommodate larger misalignments, MW’s rigid couplings ensure precise, backlash-free connections where flexibility is limited.

Additionally, MW Rigid Couplings find applications in precision instruments, robotics, and CNC machinery, where maintaining accurate shaft positioning is paramount. Their ability to handle minimal angular misalignment of 0.2 degrees makes them compatible with high-precision equipment requiring minimal play and maximum torque transfer efficiency. This is particularly important in automated production lines and robotics where alignment accuracy directly affects product quality and operational reliability.

Overall, MW Rigid Couplings are versatile components suitable for industrial environments demanding strong, reliable shaft connections. They complement other coupling solutions such as Flex Rigid PCB and Flexible Rubber Coupling by providing a stable alternative where rigidity and exact alignment are required. Their steel construction and zinc-plated finish ensure long-lasting performance, making them a preferred choice in mechanical power transmission applications across various industries.

Customization:

Our MW brand Rigid Couplings offer exceptional customization services tailored to meet your specific needs. Manufactured in CHINA, these flanged couplings are designed to handle a shaft misalignment of up to 0.2 degrees, ensuring precise and reliable performance. With a temperature range of 0-100 degrees Celsius and a weight of 0.5 kg, they provide robust and durable solutions for various industrial applications.

Although primarily rigid, our customization options allow integration with flexible diaphragm coupling elements to enhance flexibility where required. Additionally, we can incorporate features inspired by agricultural quick couplings to facilitate easy installation and maintenance. For applications demanding enhanced shock absorption, customization with grid spring coupling components is also available.

With a torque capacity of 1000 Nm, our Rigid Couplings are engineered for strength and efficiency, making them ideal for heavy-duty machinery. Trust MW to deliver high-quality, customizable coupling solutions that perfectly align with your operational requirements.

Support and Services:

Our Rigid Couplings product is designed for reliable and efficient mechanical connections. For technical support, please refer to the product manual for installation guidelines, maintenance procedures, and troubleshooting tips. Ensure proper alignment and secure fastening to maintain optimal performance. Regular inspection is recommended to detect any wear or damage early. Our technical team is available to assist with any complex issues or customization requests to meet your specific application needs.

We also offer a range of services including product selection assistance, custom engineering solutions, and on-site support. Comprehensive training sessions can be provided to help your team understand installation and maintenance best practices. For warranty information and service agreements, please consult the product documentation or contact your local representative.

Packing and Shipping:

Our rigid couplings are carefully packaged to ensure maximum protection during transit. Each coupling is individually wrapped in protective material and securely placed in a sturdy box to prevent any damage. For bulk orders, couplings are organized in custom-sized cartons with appropriate cushioning to maintain product integrity.

We offer reliable shipping options to meet your delivery requirements. All orders are processed promptly and dispatched through trusted carriers to guarantee timely arrival. Tracking information is provided for every shipment to keep you informed throughout the delivery process.

For international shipments, we ensure compliance with all export regulations and provide necessary documentation to facilitate smooth customs clearance.

FAQ:

Q1: What brand manufactures the Rigid Couplings?

A1: The Rigid Couplings are manufactured by the brand MW.

Q2: Where are the MW Rigid Couplings made?

A2: The MW Rigid Couplings are made in China.

Q3: What is the model number for the MW Rigid Couplings?

A3: The MW Rigid Couplings do not have a specific model number.

Q4: What materials are used to make MW Rigid Couplings?

A4: MW Rigid Couplings are typically made from high-quality metal alloys to ensure durability and strength.

Q5: What applications are MW Rigid Couplings suitable for?

A5: MW Rigid Couplings are suitable for applications requiring precise shaft alignment and secure mechanical connection, commonly used in industrial machinery and equipment.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Tyre Coupling , type F040 F050 F060 F070 F080 F090 F100 F110

-

Taper Lock Rigid Coupling , type RM12 , RM16 , RM25 , RM30

-

MH Coupling , type MH-55 , MH-65 , MH-80 ,MH-90 ,MH-115

-

NM Coupling , type NM50 ,NM67 , NM82 , NM97 , NM112

-

HRC Coupling , type HRC70 , HRC90 , HRC110 , HRC130

-

Tyre Coupling , typeF120 F140 F160 F180 F200 F220 F250