|

|

|

|

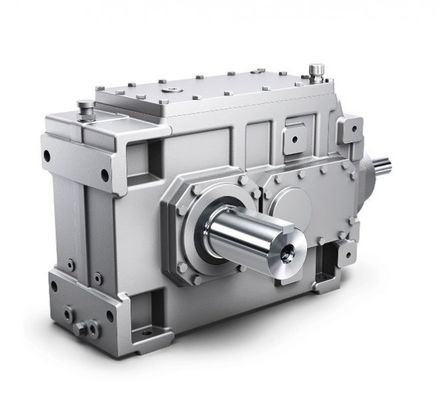

200 RPM Output Speed Double Reduction Worm Gear Reducer Planetary Type Durable Industrial Gearbox for Heavy Duty Applications

| Gearing Arrangement: | Planetary | Operating Temperature: | 0-50°C |

|---|---|---|---|

| Lubrication: | Grease | Output Speed: | 200 RPM |

| Ratio: | 5:1 | Input Power: | 1 KW |

| Material: | Cast Iron | Shaft Diameter: | 50 Mm |

Product Description:

The Gearbox reducer is a high-performance planetary gear motor reducer designed to deliver efficient and reliable speed reduction for various industrial applications. Engineered with precision, this gearbox transmission part offers a robust solution to optimize torque and speed, ensuring smooth and consistent operation in demanding environments. With an input speed of 1000 RPM and an output speed of 200 RPM, this reducer achieves a ratio of 5:1, making it ideal for applications requiring moderate speed reduction coupled with increased torque.

This planetary gearbox reducer is characterized by its compact design and high efficiency. The planetary gear mechanism allows for an even distribution of load across multiple gears, which not only enhances durability but also minimizes wear and tear. The 50 mm shaft diameter provides a solid and stable connection, ensuring reliable power transmission and reducing the risk of mechanical failure. This makes it suitable for integration into a wide range of machinery where space is limited but performance cannot be compromised.

One of the critical features of this gear motor reducer is its incorporation of helical gears in the speed reduction process. The helical gear speed reducer design ensures smoother and quieter operation compared to traditional spur gears. Helical gears engage gradually and maintain constant contact, reducing noise and vibration while increasing the overall efficiency of the gearbox. This characteristic makes the product especially suitable for applications where noise reduction is a priority, such as in manufacturing plants, conveyors, and automated systems.

The gearbox transmission parts used in this planetary reducer are manufactured from high-quality materials, ensuring long service life and resistance to harsh operating conditions. Precision machining and advanced heat treatment processes contribute to its strength and reliability, providing excellent performance even under high torque loads. The reducer’s ability to handle high input speeds while delivering a reduced output speed makes it versatile for use in various sectors including robotics, packaging machinery, material handling, and more.

In addition to its mechanical advantages, the planetary gear motor reducer is designed for easy installation and maintenance. The standardized 50 mm shaft diameter allows for compatibility with a wide range of motors and equipment, facilitating seamless integration into existing systems. Its modular design simplifies servicing and replacement of components, reducing downtime and maintenance costs.

Overall, this gearbox reducer stands out as a premium solution in the category of gear motor reducers, combining the benefits of planetary gearing with the efficiency of helical gears. Its balanced ratio of 5:1 ensures optimal performance for applications needing reliable speed reduction without sacrificing torque. Whether used in industrial automation, conveyor systems, or heavy-duty machinery, this planetary gear motor reducer delivers dependable power transmission and operational efficiency.

To summarize, the key specifications of this product include an input speed of 1000 RPM, an output speed of 200 RPM, a shaft diameter of 50 mm, and a planetary type configuration with a 5:1 ratio. The integration of helical gear technology further enhances its performance, making it a top choice among gearbox transmission parts for engineers and system designers seeking a durable, efficient, and quiet gear motor reducer.

Features:

- Product Name: Gearbox reducer

- Type: Planetary

- Ratio Options: 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1

- Input Power: 1 KW

- Operating Temperature Range: 0-50°C

- Specialized as an Industrial Reducer Gear for enhanced durability

- Designed to function efficiently as a Gear Speed Reducer

- Reliable Industrial Reducer Gear for various industrial applications

Technical Parameters:

| Operating Temperature | 0-50°C |

| Lubrication | Grease |

| Type | Planetary |

| Weight | 10 Kg |

| Material | Cast Iron |

| Output Speed | 200 RPM |

| Input Power | 1 KW |

| Shaft Diameter | 50 Mm |

| Ratio | 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1 |

| Output Torque | 500 Nm |

Applications:

The MW Gearbox Reducer, originating from China, is a high-quality planetary type reducer that is engineered to meet diverse industrial needs. With an input power of 1 KW, an input speed of 1000 RPM, and an output speed of 200 RPM, this reducer efficiently transforms speed while delivering reliable torque transmission. The shaft diameter of 50 mm ensures compatibility with a broad range of machinery, making it a versatile component in various mechanical applications.

This Carbon Steel Reducer is particularly suited for environments where durability and strength are critical. Its robust construction using carbon steel materials guarantees long-lasting performance and resistance to wear and tear. The planetary design offers compactness and high torque density, making it ideal for applications where space is limited but power requirements remain high.

The Helical Bevel Gear Reducer feature of the MW gearbox ensures smooth and quiet operation, which is essential in industries that demand low noise levels. The helical bevel gears provide efficient power transmission with minimal backlash, improving the overall performance and lifespan of the equipment. This makes the MW Gearbox Reducer a preferred choice for precision machinery and automation systems.

Common application occasions for the MW Gearbox Reducer include conveyor systems, packaging machinery, robotics, and material handling equipment. It is extensively used in manufacturing plants where precise speed control and torque are necessary to maintain productivity and ensure product quality. The planetary type gearbox design also makes it suitable for use in automotive assembly lines and heavy-duty industrial machines.

Furthermore, the MW Helical Bevel Gear Reducer is widely applied in renewable energy sectors such as wind turbines, where reliability and efficiency are paramount. Its compact size and high performance enable seamless integration with other mechanical components, facilitating optimal energy conversion and power management.

In summary, the MW Gearbox Reducer, with its planetary type configuration, carbon steel durability, and helical bevel gear technology, is perfectly equipped for a wide range of industrial applications. Whether in manufacturing, automation, or renewable energy, this reducer delivers consistent, efficient, and reliable performance, making it an indispensable component in modern mechanical systems.

Customization:

MW offers customized Gearbox Reducer solutions designed to meet your specific requirements. Our planetary type gearbox reducer features a sturdy cast iron construction, ensuring durability and long-lasting performance. With a shaft diameter of 50 mm and a mounting position optimized for horizontal installation, this product is ideal for various industrial applications.

Originating from China, our Gearbox Reducer boasts a precise 5:1 ratio, providing efficient torque transmission and reliable speed reduction. As part of our customization services, we cater to the integration of Helical Gear Reducer components, enhancing smooth operation and noise reduction.

Whether you need Gearbox Transmission Parts or specialized Car Gearbox Parts, MW’s customization capabilities ensure that each unit is tailored to your unique specifications, delivering high-quality performance and compatibility with your existing systems.

Support and Services:

Our Gearbox Reducer product is designed to provide reliable and efficient performance in various mechanical applications. For technical support, our team of experts is available to assist with installation guidance, troubleshooting, maintenance tips, and performance optimization. We offer comprehensive services including product selection assistance, custom configuration, and replacement parts to ensure your gearbox reducer operates smoothly and meets your specific requirements. Please refer to the product manual for detailed specifications and operational instructions. Regular maintenance and proper handling will extend the lifespan and enhance the performance of your gearbox reducer.

Packing and Shipping:

Our Gearbox Reducer is carefully packaged to ensure maximum protection during transit. Each unit is securely wrapped in anti-corrosion paper and placed inside a robust, custom-fitted cardboard box. For added safety, the box is reinforced with foam padding to prevent any movement or damage.

The packaged product is then placed on a sturdy wooden pallet and strapped securely to avoid shifting during shipping. We use weather-resistant wrapping to protect the palletized goods from moisture and dust.

Shipping is handled by trusted logistics partners, ensuring timely and safe delivery to your specified location. Each shipment includes detailed documentation, including a packing list and handling instructions, to facilitate smooth customs clearance and receipt.

FAQ:

Q1: What brand manufactures this gearbox reducer?

A1: The gearbox reducer is manufactured by the brand MW.

Q2: What is the model number of this gearbox reducer?

A2: This gearbox reducer does not have a specific model number.

Q3: Where is this gearbox reducer made?

A3: This gearbox reducer is made in China.

Q4: What types of applications is the MW gearbox reducer suitable for?

A4: The MW gearbox reducer is suitable for various industrial applications including conveyor systems, machinery, and automation equipment.

Q5: What are the key features of the MW gearbox reducer?

A5: The MW gearbox reducer features high durability, efficient torque transmission, compact design, and reliable performance.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Conveyor Mill Machine Industrial Worm Gearbox Reducer

-

Different Ration Worm Transmission Gearbox Reducer

-

Tractor WPA WPS Speed Cast Iron Case Worm Gearbox Reducer

-

Aluminum Worm Gearboxes WPA WPO NMRV Gear Speed Reducer

-

Concrete Mixer 90 Degree Gearbox Reducer

-

Transmission Gearboxes NMRV Speed Reducer