|

|

|

|

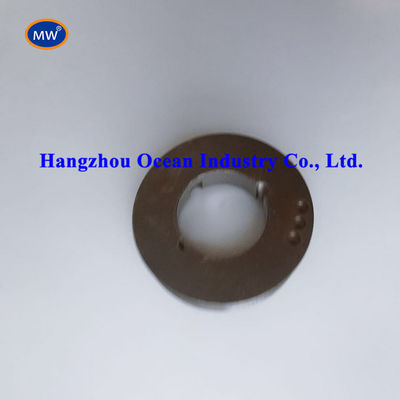

Own Mould Automotive Belt Tensioner Developed To Improve Power Transmission Systems Efficiency And Extend Component Life

| Application: | Used In Power Transmission Systems | Mould: | Own Mould Factory |

|---|---|---|---|

| Maximum Load Capacity: | Depends On Size And Type | Surface Treatment: | Black Oxide, Zinc Plated, Or Custom Coatings |

| Type: | V-Belt Pulley | Outside Diameter: | Depends On Size And Type |

| Manufacturer: | Various Manufacturers Available | Maximum Speed: | Depends On Size And Type |

Product Description:

The Belt Pulleys are essential components widely used in various industrial applications, particularly in power transmission systems. Designed to accommodate both standard and custom keyway sizes, these pulleys offer versatility and adaptability to meet the specific requirements of different machinery setups. Whether you need a standard keyway for common applications or custom sizes for specialized equipment, these belt pulleys can be precisely tailored to fit your needs, ensuring optimal performance and reliability.

Manufactured using advanced CNC machining and CNC turning processes, these belt pulleys exhibit exceptional precision and durability. The CNC machining technique allows for intricate designs and tight tolerances, which are crucial for maintaining the efficiency and smooth operation of power transmission systems. CNC turning further enhances the structural integrity and surface finish of the pulleys, making them suitable for high-speed and heavy-load applications. This combination of manufacturing processes ensures that each pulley delivers consistent performance and long-lasting service life.

Surface treatment plays a vital role in protecting belt pulleys from wear, corrosion, and environmental factors. These pulleys are available with a variety of surface coatings, including black oxide and zinc plating, as well as custom coatings tailored to specific operational demands. Black oxide treatment provides a sleek, dark finish that improves corrosion resistance and reduces friction, while zinc plating offers excellent protection against rust and environmental degradation. Custom coatings can be applied to meet unique requirements such as enhanced hardness, chemical resistance, or aesthetic preferences, making these pulleys highly adaptable to different working conditions.

One of the primary applications of these belt pulleys is in power transmission systems, where they serve as crucial components for transferring mechanical energy between shafts and belts. They are commonly used in belt conveyor machines, conveyor belts, and elevator belts, facilitating the smooth and efficient movement of materials and goods. In a belt conveyor machine, the pulley helps guide and drive the conveyor belt, ensuring consistent motion and proper tension. For conveyor belts used in manufacturing, packaging, or material handling industries, these pulleys provide reliable support and contribute to the overall efficiency of the conveyor system.

Similarly, in elevator belt systems, belt pulleys play a critical role in lifting and lowering mechanisms, offering dependable operation and safety. Their robust construction and precise engineering allow them to handle the dynamic loads and stresses encountered in elevator applications, ensuring smooth and quiet movement. The versatility of these pulleys makes them suitable for various other machinery and equipment where V-belt pulleys are required for power transmission.

Classified as V-belt pulleys, these components are specifically designed to work with V-shaped belts, which provide superior grip and torque transmission compared to flat belts. The V-belt profile allows for better alignment and reduced slippage, enhancing the overall efficiency of the power transmission system. This makes these pulleys ideal for applications requiring high power transfer, durability, and minimal maintenance.

In summary, the Belt Pulleys offered combine precision engineering, customizable sizing, advanced manufacturing techniques, and protective surface treatments to deliver outstanding performance in diverse industrial environments. Their application in belt conveyor machines, conveyor belts, and elevator belts underscores their importance in modern power transmission systems. Whether you require standard or custom keyway sizes, black oxide or zinc plating, or specialized coatings, these V-belt pulleys provide a reliable solution that meets the demands of your machinery and operational needs.

Features:

- Product Name: Belt Pulleys

- Type: V-Belt Pulley

- Customization: Customize As Drawing

- Manufacturing Process: CNC Machining, CNC Turning

- Available Colors: Natural, Black

- Number of Grooves: Single, Double, or Multi-groove

- Suitable for applications such as Engine Belt Tensioner

- Ideal for use in Conveyor Belt Press systems

- Compatible with Cable Pulley Block mechanisms

Technical Parameters:

| Keyway Size | Standard Or Custom Sizes |

| Color | Natural, Black |

| Manufacturer | Various Manufacturers Available |

| Number Of Grooves | Single, Double, Or Multi-groove |

| Application | Used In Power Transmission Systems such as Conveyor Drum Pulley, Belt Jointing Machine, and Gym Equipment Pulley |

| Type | V-Belt Pulley |

| Process | CNC Machining, CNC Turning |

| Material | Steel |

| Maximum Load Capacity | Depends On Size And Type |

| Surface Treatment | Black Oxide, Zinc Plated, Or Custom Coatings |

Applications:

The MW Belt Pulleys, originating from China, are versatile components designed to meet a broad range of industrial and automotive needs. Available in single, double, or multi-groove configurations, these pulleys can be customized according to specific drawings, ensuring precise compatibility with various machinery and equipment. Manufactured in MW's own mould factory, each pulley is crafted with high-quality materials, offered in natural or black colors, and built to endure demanding operational environments.

In automotive applications, MW Belt Pulleys are essential for systems such as the Auto Belt Tensioner and Engine Fan Pulley. The Auto Belt Tensioner relies on these pulleys to maintain the correct tension in the vehicle’s serpentine belt, ensuring smooth operation and preventing slippage or premature wear. Similarly, the Engine Fan Pulley plays a critical role in driving the engine cooling fan, helping regulate temperature and prevent overheating. The robust construction and customizable groove options of MW Belt Pulleys make them ideal for these dynamic and high-speed applications, where reliability and durability are paramount.

In industrial scenarios, MW Belt Pulleys are widely used in conveyor belt systems, where they facilitate the smooth and efficient movement of goods and materials along production lines. The availability of multiple groove options allows these pulleys to accommodate various belt types and sizes, optimizing power transmission and operational efficiency. The maximum speed capacity of each pulley depends on its size and type, making it possible to tailor solutions to specific conveyor belt requirements, whether in manufacturing, packaging, or material handling industries.

Beyond automotive and conveyor applications, MW Belt Pulleys are also suitable for a variety of machinery that requires reliable belt drive systems. Their customizable features and high manufacturing standards enable them to be integrated into bespoke equipment designs, supporting industries ranging from agriculture to construction. Choosing MW Belt Pulleys guarantees a product that combines precision engineering with flexibility, ensuring optimal performance in any occasion or scenario where belt-driven power transmission is needed.

Customization:

MW offers customized belt pulleys designed to meet your specific requirements. Manufactured in China by various manufacturers, these steel pulleys are available in single, double, or multi-groove configurations to suit different power transmission needs. Featuring a taper bore for precise fitting, our belt pulleys are ideal for applications such as engine belt tensioners, conveyor drive pulleys, and belt conveyor rollers. Whether you need a pulley for industrial machinery or conveyor systems, MW provides reliable and durable solutions tailored to your operational demands.

Support and Services:

Our Belt Pulleys are designed for optimal performance and durability in various industrial applications. For technical support, please ensure you have the pulley model number, size specifications, and application details ready to receive accurate assistance.

Installation guidance includes aligning the pulley correctly with the belt to prevent premature wear and ensuring the tension is set according to the manufacturer's recommendations. Regular inspection and maintenance of the pulleys will extend their service life and maintain system efficiency.

Replacement parts and service manuals are available to support your ongoing operational needs. For troubleshooting common issues such as noise, slipping, or misalignment, refer to the troubleshooting section in the user manual or our online resources.

We recommend using only genuine replacement parts to maintain the integrity and warranty of the Belt Pulleys. Our technical team is equipped to provide expert advice on system integration, custom solutions, and performance optimization.

Packing and Shipping:

Our belt pulleys are carefully packaged to ensure they arrive in perfect condition. Each pulley is wrapped in protective material to prevent scratches and damage during transit. The pulleys are then placed in sturdy, reinforced boxes that provide additional cushioning and support.

For shipping, we use reliable carriers with tracking options to ensure timely and safe delivery. Depending on the destination, we offer various shipping methods including standard, expedited, and express services. All packages are securely sealed and labeled with clear handling instructions to maintain product integrity throughout the shipping process.

We also provide customized packaging solutions for bulk orders or special requirements. Our goal is to deliver your belt pulleys promptly and in excellent condition, ready for immediate use.

FAQ:

Q1: What brand manufactures the Belt Pulleys?

A1: The Belt Pulleys are manufactured by the brand MW.

Q2: What is the model number of these Belt Pulleys?

A2: These Belt Pulleys do not have a specific model number.

Q3: Where are the MW Belt Pulleys made?

A3: The MW Belt Pulleys are made in China.

Q4: What materials are used to make the MW Belt Pulleys?

A4: MW Belt Pulleys are typically made from high-quality metal alloys to ensure durability and performance.

Q5: Are MW Belt Pulleys compatible with standard belt systems?

A5: Yes, MW Belt Pulleys are designed to be compatible with most standard belt systems used in industrial and mechanical applications.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378