|

|

|

|

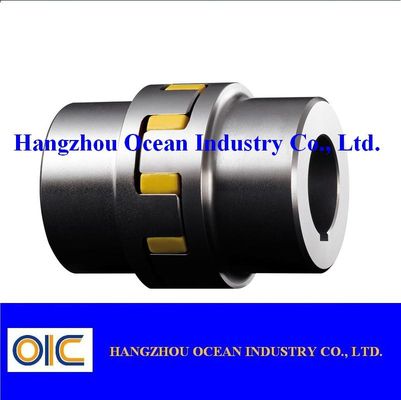

High Torsional Stiffness Flexible Coupling Parts Incorporating Misalignment Capacity ±3 Degrees for Heavy Duty Machinery

| Vibration Damping: | Yes | Installation Method: | Bolt-on |

|---|---|---|---|

| Torsional Stiffness: | High | Misalignment Capacity: | ±3° |

| Application: | Industrial Machinery | Max Speed: | 10,000 RPM |

| Temperature Range: | Up To 200°C | Material: | Stainless Steel |

Product Description:

Flexible Couplings are essential components in mechanical power transmission systems, designed to connect two shafts while accommodating misalignment and reducing the transmission of shock loads. Our Flexible Metal Coupling stands out as a superior solution, combining durability, precision, and adaptability to meet the demanding needs of modern industrial applications. Manufactured with strict adherence to ISO 9001 standards and certified with CE marking, these couplings guarantee exceptional quality, safety, and reliability.

One of the primary advantages of our Flexible Couplings is their ability to operate efficiently across a broad temperature range, withstanding conditions up to 200°C. This impressive thermal tolerance ensures that the couplings maintain their mechanical integrity and performance even in high-temperature environments, making them suitable for industries such as automotive, manufacturing, chemical processing, and power generation.

Corrosion resistance is another critical attribute of our Flexible Metal Coupling. Constructed from high-grade materials and finished with advanced protective coatings, these couplings excel in resisting corrosion from harsh chemicals, moisture, and other environmental factors. This high corrosion resistance extends the service life of the coupling, minimizes maintenance requirements, and reduces downtime, delivering exceptional value and reliability in challenging operating conditions.

In terms of mechanical performance, our Flexible Couplings offer high torsional stiffness, ensuring efficient torque transmission between connected shafts without excessive twisting or backlash. This characteristic is vital for maintaining precise alignment and smooth operation of machinery, preventing wear and tear on components, and reducing vibration and noise. The enhanced torsional stiffness translates into improved overall system performance and longevity.

Unlike Flange Rigid Couplings, which provide a solid, inflexible connection between shafts, Flexible Couplings are specifically engineered to provide a degree of flexibility. This flexibility allows them to accommodate shaft misalignments—including angular, parallel, and axial deviations—thereby protecting connected equipment from damage due to misalignment-induced stresses. This makes flexible couplings ideal for applications where slight misalignment is unavoidable or where vibration dampening is necessary.

Our product range also includes coupling sleeves that serve as integral components within the flexible coupling system. The coupling sleeve acts as a protective and functional element, encasing the internal flexible components and ensuring secure connection between the shafts. These sleeves are designed to withstand mechanical stress and environmental challenges, complementing the flexible coupling’s performance and enhancing overall durability.

When selecting a coupling for your mechanical system, it is crucial to consider factors such as operational temperature, environmental exposure, torsional requirements, and alignment conditions. Our Flexible Metal Couplings meet these criteria comprehensively, providing a reliable and versatile solution for diverse industrial applications. They are easy to install and maintain, offering a cost-effective alternative to rigid couplings without compromising on strength or performance.

In summary, our Flexible Couplings are precision-engineered products certified to ISO 9001 and CE standards, capable of operating at temperatures up to 200°C with high corrosion resistance and superior torsional stiffness. They provide flexibility that rigid flange couplings cannot, effectively compensating for misalignments and protecting machinery from damage. Coupling sleeves included in the design enhance the mechanical integrity and longevity of the system. Whether upgrading existing equipment or designing new machinery, our flexible couplings offer an optimal blend of durability, performance, and adaptability essential for modern industrial demands.

Features:

- Product Name: Flexible Couplings

- High torsional stiffness for reliable performance

- Silver color for a sleek and professional appearance

- Maximum speed up to 10,000 RPM suitable for high-speed applications

- Easy bolt-on installation method for quick setup

- High corrosion resistance ensuring durability in harsh environments

- Compatible with Hydraulic Coupling systems

- Ideal for use as a Hydraulic Coupling solution

- Incorporates Ball Joint Coupling features for enhanced flexibility

Technical Parameters:

| Max Torque | 500 Nm |

| Max Speed | 10,000 RPM |

| Misalignment Capacity | ±3° |

| Torsional Stiffness | High |

| Installation Method | Bolt-on |

| Corrosion Resistance | High |

| Vibration Damping | Yes |

| Type | Flexible |

| Temperature Range | Up To 200°C |

| Color | Silver |

Applications:

The MW Flexible Metal Coupling, manufactured in China, is an essential component designed to enhance the performance and reliability of industrial machinery. With a maximum torque capacity of 500 Nm and a max speed of up to 10,000 RPM, this flexible coupling is ideal for applications requiring robust and precise power transmission. Its flange connection type ensures secure and stable installation, accommodating various sizes to meet diverse industrial needs.

Flexible Metal Coupling from MW is widely used in a variety of industrial scenarios where equipment flexibility and vibration dampening are critical. In manufacturing plants, it connects motors to pumps, compressors, and gearboxes, providing smooth torque transfer while compensating for misalignment and shaft movement. This capability reduces wear and tear on machinery, minimizing downtime and maintenance costs.

Another common application occasion for the MW Flexible Metal Coupling is in automated production lines where high-speed rotation and torque transmission are required. Its ability to handle speeds up to 10,000 RPM makes it suitable for high-performance equipment, including CNC machines, conveyor systems, and robotic arms. The coupling’s flexible nature ensures that transient shocks and vibrations do not propagate through the system, protecting sensitive components and ensuring operational stability.

In addition to mechanical applications, the MW Flexible Metal Coupling plays a significant role in hydraulic systems when paired with Hydraulic Quick Coupling solutions. This integration allows for rapid connection and disconnection of hydraulic lines while maintaining reliable torque transmission between rotating parts. This is particularly valuable in mobile machinery, construction equipment, and agricultural machines where frequent maintenance or tool changes are necessary.

Overall, the MW Flexible Metal Coupling’s versatility in size options, combined with its high torque and speed capabilities, makes it a versatile solution across multiple industrial sectors. Whether in heavy machinery, automotive manufacturing, or fluid power systems, this coupling delivers dependable performance, flexibility, and durability, meeting the rigorous demands of modern industrial applications.

Customization:

MW offers customized product services for our Aluminum Flexible Coupling, designed to meet your specific requirements. Manufactured in CHINA, our flexible couplings feature excellent vibration damping capabilities and a misalignment capacity of ±3°, ensuring reliable and efficient performance in various applications. The connection type is flange, providing secure and easy installation. Our Flexible Metal Couplings come in a sleek silver color and are certified with ISO 9001 and CE standards, guaranteeing high quality and safety. Whether you need Hydraulic Hose Couplings or other flexible coupling solutions, MW is committed to delivering tailored products that fit your needs perfectly.

Support and Services:

Our Flexible Couplings are designed to provide reliable and efficient performance in a wide range of industrial applications. To ensure optimal operation and longevity, we offer comprehensive technical support and services tailored to your specific needs.

Our technical support team is available to assist with installation guidance, troubleshooting, maintenance recommendations, and performance optimization. We provide detailed product documentation, including specifications, installation manuals, and maintenance guidelines to help you get the most out of your Flexible Couplings.

In addition, we offer inspection and repair services to extend the life of your couplings and minimize downtime. Our experts can evaluate your existing equipment and recommend the best solutions to enhance your system’s efficiency.

For custom applications, we provide engineering support to help you select or design the right Flexible Coupling that meets your operational requirements and environmental conditions.

We are committed to delivering exceptional customer service and technical expertise to support your business operations effectively.

Packing and Shipping:

Our Flexible Couplings are carefully packaged to ensure maximum protection during transit. Each coupling is individually wrapped in protective material to prevent scratches and damage. The products are then securely placed in sturdy, cushioned boxes designed to absorb shocks and vibrations.

For shipping, we use reliable carriers with tracking options to ensure timely and safe delivery. Packages are clearly labeled with handling instructions and destination details. We also offer customized packaging solutions upon request to meet specific customer requirements.

Whether shipping domestically or internationally, we prioritize the integrity of our Flexible Couplings to guarantee they arrive in perfect condition and ready for immediate use.

FAQ:

Q1: What brand manufactures the Flexible Couplings?

A1: The Flexible Couplings are manufactured by the brand MW.

Q2: Where are the MW Flexible Couplings made?

A2: These Flexible Couplings are made in China.

Q3: Are there specific model numbers for the MW Flexible Couplings?

A3: No, the MW Flexible Couplings do not have specific model numbers.

Q4: What materials are used in the MW Flexible Couplings?

A4: The MW Flexible Couplings are typically made from high-quality metals and elastomer components to ensure flexibility and durability.

Q5: What applications are MW Flexible Couplings suitable for?

A5: MW Flexible Couplings are suitable for various industrial applications requiring the connection of rotating shafts while accommodating misalignment and reducing vibration.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200