|

|

|

|

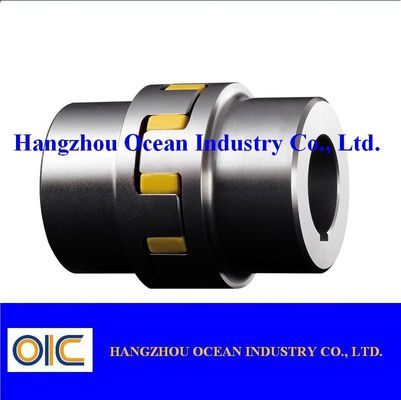

Bolt-on Flexible Couplings Providing High Torsional Stiffness and Silver Surface Designed for Shaft Alignment Solutions

| Type: | Flexible | Size: | Various Sizes Available |

|---|---|---|---|

| Torsional Stiffness: | High | Certifications: | ISO 9001, CE |

| Connection Type: | Flange | Application: | Industrial Machinery |

| Installation Method: | Bolt-on | Corrosion Resistance: | High |

Product Description:

The Flexible Couplings are an essential component designed to provide reliable and efficient power transmission in various industrial machinery applications. Specifically engineered to accommodate misalignment between shaft connections, these couplings offer exceptional performance, durability, and flexibility, making them ideal for demanding industrial environments. Known in the market as GR Coupling, this product line stands out for its robust construction and ability to maintain smooth operation even under challenging conditions.

One of the key features of the Flexible Couplings is their impressive misalignment capacity of ±3°. This capability allows the coupling to absorb angular misalignments, axial movements, and slight parallel offsets between connected shafts, protecting the machinery from undue stress and wear. This flexibility not only extends the lifespan of the equipment but also reduces maintenance costs and downtime, enhancing overall operational efficiency.

Designed for industrial machinery, these Flexible Couplings are capable of operating at a maximum speed of up to 10,000 RPM. This high-speed capability ensures compatibility with a wide range of machines, from pumps and compressors to conveyors and motors. The couplings efficiently transmit torque up to 500 Nm, providing the power and reliability required for heavy-duty industrial processes. This balance of speed and torque capacity makes the GR Coupling an excellent choice for diverse mechanical power transmission needs.

The construction of these couplings utilizes flexible metal coupling elements, which combine strength with flexibility. The Flexible Metal Coupling design ensures that the coupling can withstand high torque loads while compensating for misalignment and vibration. This metal flexibility helps to minimize shock loads and dampen vibrations, contributing to smoother operation and less mechanical stress on connected components. The use of high-quality materials in the Flexible Coupling Parts guarantees durability and resistance to wear, corrosion, and fatigue, even in harsh industrial environments.

GR Coupling’s flexible couplings are easy to install and maintain, featuring modular parts that allow for quick replacement and adjustment. This modularity is particularly beneficial in industrial settings where minimizing downtime is critical. The availability of various sizes and configurations means that the couplings can be tailored to fit specific machine requirements, ensuring optimal performance and compatibility.

In addition to their mechanical advantages, these flexible couplings are designed with safety and reliability in mind. By accommodating misalignment and reducing mechanical stresses, they help prevent premature failure of connected machinery components. This not only safeguards the investment in industrial equipment but also enhances workplace safety by reducing the risk of unexpected breakdowns and accidents.

Flexible Couplings are widely recognized under the GR Coupling brand for their superior quality and engineering excellence. As a trusted solution for industrial power transmission, these couplings play a vital role in maintaining the smooth and efficient operation of machinery across various industries. Whether used in manufacturing plants, processing facilities, or heavy industrial applications, the flexible metal coupling parts provide a dependable connection that withstands the rigors of continuous operation.

In summary, the Flexible Couplings offered by GR Coupling combine high-speed capacity, substantial torque transmission, and excellent misalignment accommodation into a single, reliable product. Their flexible metal coupling design ensures longevity and operational efficiency, making them an indispensable component for industrial machinery. When choosing coupling solutions that demand performance, durability, and adaptability, these flexible couplings represent an outstanding choice that meets and exceeds industrial requirements.

Features:

- Product Name: Flexible Couplings

- Certifications: ISO 9001, CE certified

- Max Speed: Up to 10,000 RPM for high-performance applications

- Material: Durable Stainless Steel construction

- Max Torque: Supports torque up to 500 Nm

- Corrosion Resistance: High corrosion resistance for long-lasting durability

- Includes Drum Gear Coupling design for enhanced flexibility and strength

- Suitable for use in Agricultural Quick Couplings to ensure fast and reliable connections

- Ideal coupling solution for various industrial and agricultural applications

Technical Parameters:

| Color | Silver |

| Installation Method | Bolt-on |

| Temperature Range | Up To 200°C |

| Application | Industrial Machinery |

| Misalignment Capacity | ±3° |

| Vibration Damping | Yes |

| Certifications | ISO 9001, CE |

| Material | Stainless Steel |

| Max Torque | 500 Nm |

| Max Speed | 10,000 RPM |

Applications:

The MW Flexible Shaft Coupling, originating from China, is a versatile and reliable component designed specifically for industrial machinery applications. Known for its robust construction and flexible design, this flexible coupling is engineered to accommodate misalignment capacities of ±3°, ensuring smooth and efficient power transmission even in demanding operational environments. Its silver casing coupling not only provides an aesthetically pleasing finish but also adds to the durability and corrosion resistance, making it suitable for various industrial settings.

This flexible shaft coupling is widely used in numerous application occasions where precise torque transmission and adaptability to misalignment are critical. It is ideal for connecting shafts in pumps, compressors, conveyors, and other rotating equipment commonly found in manufacturing plants, processing industries, and heavy machinery setups. The MW flexible coupling’s ability to handle a maximum torque of up to 500 Nm makes it suitable for medium to heavy-duty applications, where reliable performance and longevity are essential.

Due to its availability in various sizes, the MW Flexible Shaft Coupling can be tailored to fit a broad range of machinery specifications, providing flexibility in design and installation. This adaptability makes it an excellent choice for both new equipment assembly and maintenance or replacement in existing systems. The flexible nature of the casing coupling helps in absorbing shocks, vibrations, and minor misalignments, thereby protecting connected components from premature wear and tear.

In scenarios involving industrial automation, material handling, and power transmission systems, the MW flexible coupling ensures seamless integration and operational efficiency. Its flexible design is particularly advantageous in applications where alignment conditions may change or where shaft deflections occur during operation. This capability reduces maintenance downtime and enhances the overall reliability of machinery.

In summary, the MW Flexible Shaft Coupling from China is an indispensable solution for industrial machinery requiring a flexible, durable, and high-torque capable coupling. Its flexible casing coupling design, combined with a ±3° misalignment capacity and a silver finish, makes it a preferred choice across various industries seeking dependable shaft coupling solutions that deliver consistent performance and adaptability.

Customization:

MW offers customized product solutions for Flexible Couplings designed to meet the specific needs of industrial machinery applications. Our Flexible Metal Couplings are engineered to provide reliable performance with a maximum torque capacity of 500 Nm, ensuring efficient power transmission even under demanding conditions. Manufactured in China, these couplings are built to withstand temperatures up to 200°C, making them suitable for a wide range of operating environments.

We specialize in various types of flexible couplings, including Grooved Couplings and Ball Joint Couplings, allowing for optimal flexibility and alignment in your mechanical systems. The bolt-on installation method ensures easy assembly and maintenance, reducing downtime and improving operational efficiency. Whether you require standard or tailor-made solutions, MW is committed to delivering high-quality flexible couplings that enhance the performance and longevity of your industrial machinery.

Support and Services:

Our Flexible Couplings are designed to provide reliable and efficient performance across a variety of industrial applications. To ensure optimal operation, please follow the installation and maintenance guidelines provided in the user manual.

For installation, verify the alignment of shafts and ensure that the coupling components are free from any debris or damage. Proper lubrication, if applicable, should be maintained according to the specifications.

Regular inspection of the coupling for wear, cracks, or misalignment is recommended to prevent unexpected downtime. Replace any worn or damaged parts promptly to maintain system integrity.

Our technical support team is available to assist with troubleshooting, technical inquiries, and application advice to help you maximize the performance of your Flexible Couplings.

We also offer repair services and replacement parts to extend the life of your equipment. Please refer to the warranty terms and conditions for service coverage details.

For further assistance, consult the product documentation or visit our support website for FAQs, manuals, and instructional videos.

Packing and Shipping:

Our Flexible Couplings are carefully packaged to ensure maximum protection during transit. Each coupling is individually wrapped with protective materials to prevent damage from moisture, dust, and impact.

The couplings are then securely placed in sturdy, custom-designed boxes that provide cushioning and support. For bulk orders, products are packed in reinforced cartons with proper labeling for easy identification and handling.

We use reliable shipping methods and trusted carriers to guarantee timely delivery. All shipments include tracking information and are handled with care to maintain product integrity until they reach the customer.

FAQ:

Q1: What is a flexible coupling used for?

A: A flexible coupling is used to connect two shafts together at their ends to transmit power while accommodating some degree of misalignment, vibration, and shock.

Q2: What brand manufactures this flexible coupling?

A: This flexible coupling is manufactured by the brand MW.

Q3: Where is the MW flexible coupling made?

A: The MW flexible coupling is made in China.

Q4: Does the MW flexible coupling support misalignment between connected shafts?

A: Yes, the MW flexible coupling is designed to accommodate angular, parallel, and axial misalignment between connected shafts.

Q5: Is there a specific model number for the MW flexible coupling?

A: No, this product does not have a specific model number associated with it.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200