|

|

|

|

Temperature Range Up To 200°C Agricultural Quick Couplings With High Corrosion Resistance Providing Secure and Connections

| Material: | Stainless Steel | Temperature Range: | Up To 200°C |

|---|---|---|---|

| Torsional Stiffness: | High | Vibration Damping: | Yes |

| Application: | Industrial Machinery | Type: | Flexible |

| Certifications: | ISO 9001, CE | Corrosion Resistance: | High |

Product Description:

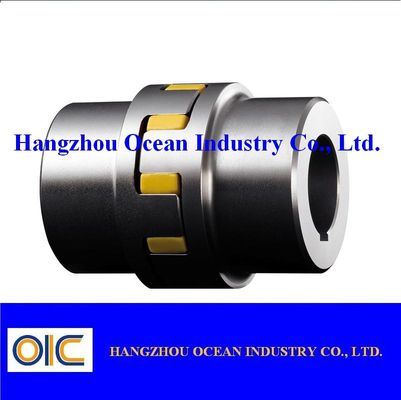

Flexible couplings are essential components in mechanical power transmission systems, designed to connect two shafts together while accommodating misalignment and reducing the transmission of shock loads. Among the various types of flexible couplings available, the Grid Spring Coupling, GR Coupling, and Casing Coupling stand out for their superior performance, reliability, and versatility in a wide range of industrial applications.

One of the most critical attributes of these flexible couplings is their high torsional stiffness. This feature ensures that the coupling can effectively transmit torque with minimal angular displacement, providing precise and efficient power transfer between connected shafts. The high torsional stiffness of Grid Spring Couplings, GR Couplings, and Casing Couplings makes them ideal for applications where accurate positioning and vibration damping are crucial, such as in pumps, compressors, and heavy-duty machinery.

These flexible couplings are engineered to handle a maximum torque of up to 500 Nm, making them suitable for medium to high power transmission requirements. The robust design allows them to sustain heavy loads and sudden torque spikes without compromising performance or safety. This capability is particularly important in industries where machinery operates under fluctuating loads and demanding conditions.

Corrosion resistance is another vital characteristic of these couplings. Manufactured from high-quality materials and often treated with protective coatings, Grid Spring Couplings, GR Couplings, and Casing Couplings offer excellent resistance to corrosive environments. This makes them highly reliable in harsh industrial settings, including chemical plants, marine applications, and outdoor installations where exposure to moisture, chemicals, and other corrosive agents is common. The enhanced corrosion resistance not only extends the service life of the couplings but also reduces maintenance costs and downtime.

Flexibility in sizing is a significant advantage of these flexible couplings. They are available in various sizes to accommodate different shaft diameters and application requirements. This versatility ensures that engineers and maintenance professionals can select the most suitable coupling size to optimize performance and fit seamlessly within existing mechanical systems. Whether the application involves small precision equipment or large industrial machinery, there is a Grid Spring Coupling, GR Coupling, or Casing Coupling size that meets the specific needs.

Quality and reliability are guaranteed through rigorous manufacturing processes and adherence to international standards. These flexible couplings are certified under ISO 9001 and CE, reflecting their compliance with stringent quality management systems and safety regulations. These certifications provide assurance to users that the couplings meet global standards for performance, durability, and environmental impact, making them a trusted choice for critical applications worldwide.

In summary, flexible couplings such as the Grid Spring Coupling, GR Coupling, and Casing Coupling offer a high-performance solution for torque transmission with their exceptional torsional stiffness, high corrosion resistance, and capacity to handle up to 500 Nm of torque. Their availability in various sizes and compliance with ISO 9001 and CE certifications make them versatile, reliable, and safe components suitable for a broad spectrum of industrial uses. Investing in these flexible couplings ensures enhanced operational efficiency, reduced maintenance, and prolonged equipment lifespan, making them indispensable in modern mechanical systems.

Features:

- Product Name: Flexible Couplings

- Application: Industrial Machinery

- Misalignment Capacity: ±3° for enhanced alignment tolerance

- Temperature Range: Up to 200°C suitable for high-temperature environments

- Max Torque: 500 Nm to handle demanding torque requirements

- Torsional Stiffness: High torsional stiffness for reliable power transmission

- Includes Casing Coupling for robust protection and durability

- Flexible Rubber Coupling design ensures vibration damping and flexibility

- Compatible with Agricultural Quick Couplings for easy and fast installation

Technical Parameters:

| Application | Industrial Machinery |

| Torsional Stiffness | High |

| Temperature Range | Up To 200°C |

| Material | Stainless Steel |

| Vibration Damping | Yes |

| Installation Method | Bolt-on |

| Certifications | ISO 9001, CE |

| Connection Type | Flange |

| Misalignment Capacity | ±3° |

| Max Torque | 500 Nm |

Applications:

The MW Flexible Couplings, proudly manufactured in China, are engineered to provide superior performance in a wide range of industrial applications. These couplings are designed to accommodate misalignment with a capacity of ±3°, making them ideal for scenarios where shaft alignment cannot be perfectly maintained. The flexible nature of MW couplings ensures smooth power transmission while reducing stress on connected equipment.

Flexible couplings from MW are available in various sizes, catering to different mechanical requirements and installation constraints. Their flange connection type provides a secure and reliable method of attachment, facilitating easy assembly and disassembly during maintenance or replacement. With a maximum torque capacity of 500 Nm, these couplings are suitable for medium to high torque applications, ensuring durability and efficiency in power transmission systems.

One of the primary application occasions for MW Flexible Couplings is in manufacturing plants where machinery often experiences minor shaft misalignments due to thermal expansion, foundation settling, or assembly errors. The flexibility of these couplings absorbs vibrations and compensates for angular, parallel, and axial misalignments, thereby protecting both the motor and driven equipment from premature wear.

In addition to flexible couplings, MW also offers Flange Rigid Coupling and GR Coupling options for applications requiring different levels of rigidity and torque transmission. Flange Rigid Couplings are typically used in situations where precise shaft alignment is achievable and rigidity is paramount, such as in heavy-duty industrial drives and conveyor systems. Meanwhile, GR Couplings provide a balance of flexibility and strength, making them suitable for applications involving moderate misalignment and torque requirements.

MW Flexible Couplings are extensively utilized in sectors like automotive manufacturing, packaging machinery, pumps, compressors, and HVAC systems. Their ability to accommodate misalignment and reduce vibration makes them especially valuable in environments where equipment undergoes frequent start-stop cycles or experiences varying load conditions. The flange connection type also simplifies integration into existing drive systems, reducing downtime and maintenance costs.

Overall, MW’s flexible coupling solutions, along with their flange rigid and GR coupling variants, provide versatile and reliable options for engineers and maintenance professionals seeking to enhance the longevity and performance of their mechanical systems. Whether it’s for new installations or retrofitting existing equipment, MW couplings deliver consistent torque transmission and operational stability across a broad spectrum of industrial scenarios.

Customization:

MW offers customized product solutions for Flexible Couplings designed to meet your specific application needs. Our Flexible Coupling Parts are engineered with high corrosion resistance, ensuring durability and long-lasting performance even in harsh environments. The flexible element coupling design provides excellent vibration damping, reducing wear and enhancing operational stability. Manufactured in China, these flexible couplings feature a convenient bolt-on installation method for easy integration into your machinery. Available in a sleek silver color, MW Flexible Couplings combine functionality and aesthetics to deliver reliable and efficient power transmission solutions.

Support and Services:

Our Flexible Couplings product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide expert guidance on selection, installation, and maintenance to help you achieve the best results. Our technical team is available to assist with troubleshooting, application advice, and customization options tailored to your specific needs. Additionally, we offer detailed product documentation, including specifications, installation manuals, and maintenance guidelines to support your operations. For any service requirements, we provide repair and replacement services to minimize downtime and extend the life of your flexible couplings. Trust our dedicated support to keep your machinery running smoothly and efficiently.

Packing and Shipping:

Our Flexible Couplings are carefully packaged to ensure maximum protection during transit. Each coupling is individually wrapped in protective material and placed in a sturdy box to prevent any damage. For bulk orders, couplings are securely packed in reinforced cartons, with additional padding as needed.

We offer reliable shipping options worldwide, ensuring timely and safe delivery of your order. Tracking information will be provided once the shipment is dispatched. For special shipping requirements or expedited delivery, please contact our customer service team.

FAQ:

Q1: What brand manufactures the Flexible Couplings?

A1: The Flexible Couplings are manufactured by the brand MW.

Q2: Where are the MW Flexible Couplings made?

A2: The MW Flexible Couplings are made in China.

Q3: Are there specific model numbers for the MW Flexible Couplings?

A3: The MW Flexible Couplings do not have specific model numbers.

Q4: What are the main benefits of using MW Flexible Couplings?

A4: MW Flexible Couplings provide reliable torque transmission, accommodate misalignment, and reduce vibration between connected shafts.

Q5: Can MW Flexible Couplings be used in different industrial applications?

A5: Yes, MW Flexible Couplings are versatile and suitable for various industrial applications requiring flexible shaft connections.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200