|

|

|

|

Torque Capacity 1000 Nm Hydraulic Hose Couplings Offering Shaft Misalignment 0.2 Degrees Performance Under High Pressure

| Keyway Size: | 6 Mm | Shaft Diameter: | 25 Mm |

|---|---|---|---|

| Shaft Misalignment: | 0.2 Degrees | Size: | 1 Inch |

| Temperature Range: | 0-100 Degrees Celsius | Type: | Flanged |

| Material: | Steel | Weight: | 0.5 Kg |

Product Description:

The Rigid Couplings are essential components designed for use in industrial machinery, providing a reliable and robust connection between two shafts. These couplings are engineered to ensure the precise alignment and transmission of torque without any backlash or slip, making them ideal for applications where rigidity and accuracy are paramount. With a bore diameter of 25 mm, these couplings are suitable for a wide range of machinery, allowing for easy integration into existing systems while maintaining optimal performance.

One of the standout features of this Rigid Coupling is its exceptional torque capacity of 1000 Nm. This high torque rating ensures that the coupling can handle demanding operational conditions, transmitting power efficiently and reliably even under heavy loads. The coupling's size, measuring 1 inch, offers a compact yet sturdy solution that fits seamlessly into industrial setups without occupying excessive space. Despite its robust construction, the coupling maintains a lightweight profile, weighing only 0.5 kg, which helps in reducing the overall weight of the machinery and facilitates easier handling and installation.

Incorporating the benefits of a Grid Spring Coupling, this rigid coupling combines the strength and rigidity required for precision applications with the durability needed for long service life. The grid spring mechanism typically found in Grid Spring Couplings provides excellent shock absorption and vibration damping; however, in the rigid coupling design, the focus is on eliminating any relative motion between connected shafts, ensuring maximum torque transmission and alignment accuracy. This makes the Rigid Coupling an excellent choice for industries where machinery downtime is costly and operational precision is critical.

Moreover, the Rigid Coupling is compatible with IMC Rigid Conduits, allowing it to be easily integrated within conduit systems for protecting and routing electrical wiring in industrial environments. This compatibility adds to the versatility of the coupling, making it suitable for a broader range of applications where both mechanical and electrical integrity are essential. The coupling’s design facilitates secure connections, enhancing the overall safety and efficiency of the machinery systems.

Industrial machinery demands components that withstand harsh operating conditions, including high torque, misalignment challenges, and mechanical stress. The Rigid Coupling addresses these demands by providing a solid connection that prevents shaft slippage, maintains alignment, and delivers consistent performance. Its robust construction ensures durability and longevity, minimizing maintenance needs and reducing the risk of unexpected failures. This reliability contributes significantly to increased productivity and reduced downtime in industrial operations.

In summary, the Rigid Coupling with a 25 mm bore diameter, 1-inch size, and 0.5 kg weight is a powerful and dependable solution for industrial machinery applications. Its torque capacity of 1000 Nm, combined with the precision and stability offered by the Grid Spring Coupling design principles, makes it an indispensable component in systems requiring high-performance shaft connections. Additionally, its compatibility with IMC Rigid Conduits enhances its utility in complex industrial environments, ensuring both mechanical robustness and electrical safety.

Choosing this Rigid Coupling means investing in a product that delivers exceptional torque transmission, maintains alignment accuracy, and integrates seamlessly into industrial setups. Whether used in manufacturing equipment, automation systems, or heavy machinery, this coupling stands out as a high-quality, efficient, and reliable solution tailored for the rigorous demands of industrial applications.

Features:

- Product Name: Rigid Couplings

- Temperature Range: 0-100 Degrees Celsius

- Torque Capacity: 1000 Nm

- Shaft Misalignment: 0.2 Degrees

- Surface Treatment: Zinc Plated for enhanced durability

- Max Operating Pressure: 10 Bar

- Compatible with IMC Rigid Conduits for secure installation

- Utilizes Grid Spring Coupling technology for reliable torque transmission

- Alternative to Flexible Shaft Coupling for applications requiring minimal shaft misalignment

Technical Parameters:

| Surface Treatment | Zinc Plated |

| Keyway Size | 6 Mm |

| Application | Industrial Machinery |

| Torque Capacity | 1000 Nm |

| Size | 1 Inch |

| Shaft Diameter | 25 Mm |

| Max Operating Pressure | 10 Bar |

| Bore Diameter | 25 Mm |

| Type | Flanged |

| Material | Steel |

Applications:

The MW Rigid Couplings, manufactured in China, are designed to provide reliable and robust shaft connections suitable for a wide range of industrial and agricultural applications. With a torque capacity of 1000 Nm and a shaft diameter of 25 mm, these couplings ensure efficient power transmission in demanding environments. Their steel construction guarantees high strength and durability, making them ideal for heavy-duty tasks where stability and precision are critical.

One of the primary application occasions for MW Rigid Couplings is in agricultural machinery, where they serve as essential components for Agricultural Quick Couplings systems. These couplings facilitate the transfer of torque between shafts in equipment such as tractors, harvesters, and irrigation systems. The bolted connection type ensures secure and easy assembly or disassembly, which is crucial for maintenance and equipment upgrades on farms. The rigid nature of these couplings helps maintain alignment, minimizing vibration and wear, thus enhancing the longevity of agricultural machinery.

In addition to agricultural uses, MW Rigid Couplings are widely employed in industrial settings where stable shaft connections are necessary. For instance, they can be used alongside Aluminium Coupling components in machinery that requires lightweight yet sturdy coupling solutions. The steel material of MW Rigid Couplings complements aluminium parts by providing higher torque capacity and resistance to mechanical stress. This combination is particularly beneficial in manufacturing plants and assembly lines where precision and durability are essential.

Another scenario where MW Rigid Couplings excel is in systems that otherwise utilize Flexible Rubber Coupling for vibration damping but require a more rigid connection for specific segments. While flexible rubber couplings offer flexibility and shock absorption, the rigid couplings from MW provide the necessary rigidity and torque handling in parts of the system where movement must be minimized. This makes them suitable for hybrid applications where both flexibility and rigidity are strategically needed.

Furthermore, MW Rigid Couplings can operate efficiently under a maximum operating pressure of 10 Bar, making them suitable for hydraulic machinery and equipment where pressure conditions are moderate. Their robust design ensures that they maintain performance under pressure fluctuations, contributing to the overall reliability of the connected systems.

In summary, MW Rigid Couplings are versatile components ideal for agricultural quick couplings, industrial machinery integrating aluminium coupling parts, and hybrid systems employing flexible rubber coupling elements. Their steel construction, bolted connection type, and high torque capacity make them indispensable for applications demanding strength, durability, and precise shaft alignment.

Customization:

MW offers customized product services for our Rigid Couplings, designed specifically for industrial machinery applications. Our rigid couplings feature a bolted connection type ensuring secure and reliable performance. With a bore diameter of 25 mm and a keyway size of 6 mm, these couplings are ideal for precise mechanical connections. The 1-inch size dimension caters to a wide range of industrial equipment needs. Additionally, we provide options for Grid Spring Coupling and Flexible Rigid PCB configurations to meet specialized requirements. Manufactured in China, MW rigid couplings combine durability and flexibility to enhance your machinery's efficiency and longevity.

Support and Services:

Our Rigid Couplings are designed to provide a secure and precise connection between two shafts, ensuring efficient power transmission and alignment. For technical support, please refer to the product manual that includes detailed installation instructions, maintenance guidelines, and troubleshooting tips.

Ensure that the coupling is installed according to the specified torque values and alignment requirements to prevent premature wear or failure. Regular inspection and maintenance are recommended to check for any signs of misalignment, corrosion, or damage.

If you encounter any issues with your Rigid Coupling, verify the compatibility with your application’s specifications including shaft size, torque load, and environmental conditions. For advanced support, technical datasheets and CAD files are available to assist in design and integration.

We also offer services including custom modifications, replacement parts, and expert consultation to optimize the performance of your coupling in your specific application.

Packing and Shipping:

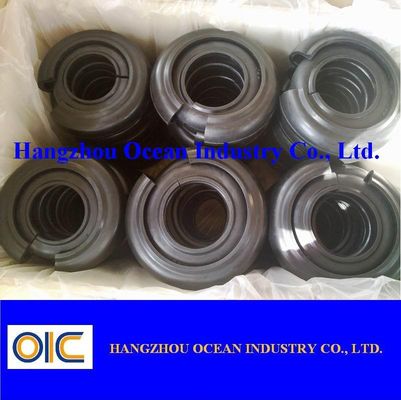

Our Rigid Couplings are carefully packaged to ensure maximum protection during transit. Each coupling is individually wrapped in protective material and placed in a sturdy box to prevent any damage. Bulk orders are securely packed on pallets with cushioning materials to avoid movement and impact.

We offer reliable shipping options to deliver your Rigid Couplings promptly and safely. Shipping methods include standard ground transport, expedited air freight, and international shipping services. Tracking information will be provided once your order is dispatched to keep you informed throughout the delivery process.

For large or customized orders, please contact our sales team to discuss special packaging and shipping requirements. We are committed to providing you with high-quality products and a seamless delivery experience.

FAQ:

Q1: What brand manufactures the Rigid Couplings?

A1: The Rigid Couplings are manufactured by the brand MW.

Q2: Where are the MW Rigid Couplings made?

A2: The MW Rigid Couplings are made in China.

Q3: Are there different model numbers available for the MW Rigid Couplings?

A3: No, the MW Rigid Couplings do not have specific model numbers.

Q4: What applications are MW Rigid Couplings suitable for?

A4: MW Rigid Couplings are suitable for applications requiring a secure connection between two shafts that do not allow any relative motion.

Q5: What materials are used to make MW Rigid Couplings?

A5: MW Rigid Couplings are typically made from high-quality metal materials to ensure durability and strength.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Tyre Coupling , type F040 F050 F060 F070 F080 F090 F100 F110

-

Taper Lock Rigid Coupling , type RM12 , RM16 , RM25 , RM30

-

MH Coupling , type MH-55 , MH-65 , MH-80 ,MH-90 ,MH-115

-

NM Coupling , type NM50 ,NM67 , NM82 , NM97 , NM112

-

HRC Coupling , type HRC70 , HRC90 , HRC110 , HRC130

-

Tyre Coupling , typeF120 F140 F160 F180 F200 F220 F250