|

|

|

|

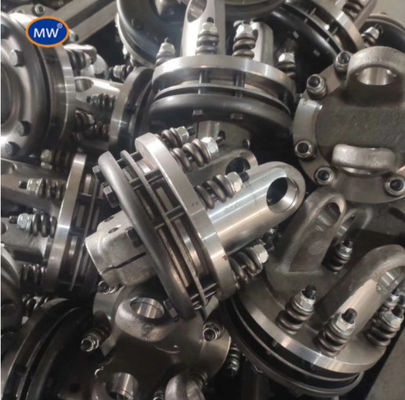

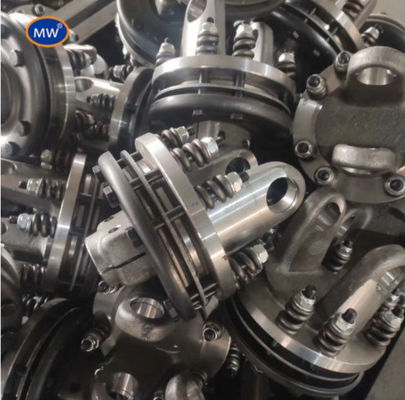

Length 1.5 Meters Drive Shaft Welding Machine Incorporating Splined End Length 50 Mm Perfect for Shaft Welding Processes

| Material: | Steel | Power Source: | Pto Shaft Tube |

|---|---|---|---|

| Maximum Speed: | 1000 Rpm | Splined End Length: | 50 Mm |

| Safety Features: | Overload Protection | Splined End Size: | 20 Teeth |

| Flange Thickness: | 20 Mm | Certifications: | ISO 9001 |

Product Description:

The PTO Drive Shafts are precision-engineered components designed to deliver reliable and efficient power transmission in various industrial and agricultural machinery. Crafted with high-quality materials and manufactured under stringent quality control processes, these drive shafts ensure optimal performance and longevity. Certified to meet the rigorous standards of ISO 9001, the PTO Drive Shafts guarantee consistency, durability, and reliability, making them an ideal choice for demanding applications.

One of the standout features of this PTO Drive Shaft is its splined end diameter of 60 mm, which allows for a secure and seamless connection to compatible machinery parts. The splined design ensures efficient torque transfer and minimizes the risk of slippage, thereby enhancing the overall performance of the drive system. With a length of 1.5 meters, this drive shaft is versatile enough to accommodate a wide range of equipment sizes and configurations, providing flexibility for various operational requirements.

The flange thickness, measuring 20 mm, adds to the robustness and stability of the connection between the drive shaft and adjoining components. This dimension is critical in maintaining structural integrity and reducing wear and tear during heavy-duty operations. The flange design also facilitates easy installation and maintenance, contributing to reduced downtime and improved productivity in the field.

Safety is paramount when dealing with power transmission components, and the PTO Drive Shafts incorporate advanced overload protection features to safeguard both the machinery and the operator. This safety mechanism helps to prevent damage caused by excessive torque or sudden shocks, thereby extending the lifespan of the drive shaft and associated equipment. Overload protection also minimizes the risk of accidents and costly repairs, ensuring a safer working environment.

These PTO Drive Shafts are ideal for use in conjunction with gear shafts, CV axle shafts, and drive axle shafts, forming an integral part of the drivetrain system. Their compatibility with these components makes them highly adaptable for various machinery types, including tractors, harvesters, and other heavy-duty vehicles. The precision splines and reinforced flange ensure seamless integration, resulting in smooth and efficient power delivery from the engine to the working parts of the machine.

In addition to their mechanical advantages, the PTO Drive Shafts are designed to withstand harsh operating conditions, including exposure to dirt, moisture, and varying temperatures. Their robust construction and protective coatings help resist corrosion and mechanical fatigue, further enhancing their durability and reliability over time. This resilience makes them a cost-effective investment for businesses looking to minimize maintenance costs and maximize equipment uptime.

Overall, the PTO Drive Shafts represent a perfect blend of engineering excellence, safety, and versatility. Their ISO 9001 certification underscores a commitment to quality and continuous improvement, while their detailed specifications—such as the 60 mm splined end diameter, 1.5-meter length, and 20 mm flange thickness—highlight their suitability for demanding applications. With built-in overload protection and compatibility with essential drivetrain components like gear shafts, CV axle shafts, and drive axle shafts, these PTO Drive Shafts are engineered to deliver superior performance and reliability in the most challenging environments.

Features:

- Product Name: PTO Drive Shafts

- Maximum Torque: 500 Nm

- Safety Features: Overload Protection for enhanced durability

- Certifications: ISO 9001 certified ensuring quality and reliability

- Splined End Length: 50 mm for precise fitment

- Splined End Diameter: 60 mm compatible with various Excavator Drive Motor applications

- Manufactured using high-quality Forging Shafts technology

- Incorporates advanced Ceramic Shaft components for improved performance and longevity

Technical Parameters:

| Splined End Length | 50 Mm |

| Power Source | Pto Shaft Tube |

| Shaft Diameter | 50 Mm |

| Length | 1.5 Meters |

| Maximum Speed | 1000 Rpm |

| Maximum Torque | 500 Nm |

| Splined End Diameter | 60 Mm |

| Weight | 10 Kg |

| Certifications | ISO 9001 |

| Safety Features | Overload Protection |

Applications:

The MW PTO Drive Shafts, originating from China and certified with ISO 9001, are designed to deliver reliable and efficient power transmission in a variety of industrial and agricultural applications. With a length of 1.5 meters and a weight of 10 kg, these drive shafts are engineered to handle demanding environments while ensuring durability and performance. Powered by a robust PTO shaft tube, the MW drive shafts can operate at a maximum speed of 1000 RPM, making them suitable for high-speed machinery and equipment.

One of the primary application occasions for the MW PTO Drive Shafts is in agricultural machinery, where power take-off systems are essential for transferring engine power to various implements. The drive shaft’s compatibility with ceramic shaft components enhances its wear resistance and longevity, even under continuous heavy-duty use. This makes it an ideal choice for farmers looking to improve the efficiency of their tractors, harvesters, and other PTO-driven equipment.

Another significant scenario for the MW PTO Drive Shafts is in construction and excavation equipment. Specifically, these drive shafts are well-suited for excavator drive motors, where precision and reliability are crucial. The integration with excavator drive sprockets ensures smooth power transmission and optimal torque delivery, enabling excavators to perform heavy lifting and digging tasks effectively. The high-speed capability of 1000 RPM allows for responsive and efficient operation in various terrains and working conditions.

Additionally, the MW PTO Drive Shafts are highly applicable in industrial settings where machinery requires a dependable connection between the power source and driven components. Their robust construction and ISO 9001 certification guarantee quality and performance, making them suitable for use in manufacturing plants, material handling systems, and other mechanical assemblies where PTO-driven operations are essential.

In summary, the MW PTO Drive Shafts are versatile components designed to meet the rigorous demands of agricultural, construction, and industrial applications. Their ceramic shaft construction, compatibility with excavator drive motors and sprockets, and adherence to international quality standards make them a dependable choice for professionals seeking durability and efficiency in power transmission solutions.

Customization:

MW offers customized PTO Drive Shafts designed to meet your specific requirements. Our drive shafts feature a splined end size of 20 teeth and a shaft diameter of 50 mm, ensuring compatibility with a variety of Flex Shaft Machines. Manufactured from high-quality forged steel shafts, these components provide exceptional strength and durability for demanding applications. The power source is a PTO shaft tube, capable of handling a maximum speed of 1000 RPM, making them ideal for use as reliable drive axle shafts in agricultural and industrial machinery. Originating from CHINA, MW's PTO Drive Shafts combine precision engineering with robust materials to deliver superior performance and longevity.

Support and Services:

Our PTO Drive Shafts are designed to deliver reliable power transmission for a wide range of agricultural and industrial machinery. To ensure optimal performance and longevity, it is important to follow the recommended maintenance and safety guidelines.

For technical support, we provide detailed installation instructions, maintenance manuals, and troubleshooting guides to assist you in resolving common issues. Our support team is trained to help with product selection, compatibility questions, and operational advice.

Regular inspection of the PTO Drive Shaft for wear, lubrication needs, and alignment is crucial. Always use the specified grease and replace any worn or damaged components promptly to prevent failure.

We also offer repair services and replacement parts to extend the life of your PTO Drive Shaft. Our technicians are equipped to handle repairs efficiently, minimizing downtime.

Ensure all safety shields and guards are in place before operating machinery with PTO Drive Shafts. Proper safety protocols protect both the operator and the equipment.

For detailed service schedules and additional support resources, please refer to the product documentation provided with your PTO Drive Shaft.

Packing and Shipping:

Our PTO Drive Shafts are carefully packaged to ensure maximum protection during transit. Each shaft is securely wrapped with protective materials to prevent damage from impacts, moisture, and dust. The packaging is designed to keep the product in pristine condition until it reaches the customer.

For shipping, we use sturdy, high-quality boxes and pallets to handle the weight and size of the PTO Drive Shafts. All shipments are tracked and insured for added security. We offer reliable shipping options to deliver your product promptly and safely to your desired location.

FAQ:

Q1: What brand manufactures the PTO Drive Shafts?

A1: The PTO Drive Shafts are manufactured by the brand MW.

Q2: Is there a specific model number for the MW PTO Drive Shafts?

A2: No, the MW PTO Drive Shafts do not have a specific model number.

Q3: Where are the MW PTO Drive Shafts produced?

A3: The MW PTO Drive Shafts are made in China.

Q4: What applications are the MW PTO Drive Shafts suitable for?

A4: MW PTO Drive Shafts are typically used in agricultural machinery to transfer power from tractors to implements.

Q5: How do I ensure proper maintenance of the MW PTO Drive Shafts?

A5: Regular lubrication, inspection for wear and damage, and proper installation are key to maintaining the MW PTO Drive Shafts in good working condition.

pto shaft,

tractor pto shaft

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Power Transmission PTO Drive Shafts For Rotary Tiller , power take off shaft

-

Agricultural Tractor PTO Drive Shafts replacement / custom made drive shafts

-

Professiona Farm Cardan PTO Drive Shafts with Overruning Clutch

-

Custom Planter Machine PTO Drive Shafts Ratchet Torque Limiter driving shaft

-

Auto parts flexible drive shaft PTO / Cardan Shaft for Agriculture Rotavator

-

4x4 Power Take off PTO Drive Shafts Shear Bolt Torque Limiter