|

|

|

|

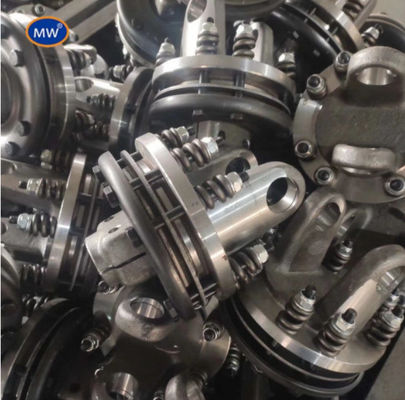

Splined End Length 50 Mm Drive Shaft Center Bearing Designed for Maximum Speed 1000 Rpm Applications in Heavy Machinery

| Keyway Size: | 10 Mm | Splined End Length: | 50 Mm |

|---|---|---|---|

| Power Source: | Pto Shaft Tube | Material: | Steel |

| Shaft Diameter: | 50 Mm | Maximum Speed: | 1000 Rpm |

| Flange Diameter: | 100 Mm | Splined End Diameter: | 60 Mm |

Product Description:

The PTO Drive Shafts are precision-engineered components designed to deliver reliable power transmission in various heavy-duty applications. Featuring a flange diameter of 100 mm and a shaft diameter of 50 mm, these drive shafts are built to withstand substantial mechanical stress while ensuring smooth and efficient operation. With a length of 1.5 meters, the shaft provides optimal reach and flexibility for a wide range of machinery, making it an essential part of power take-off systems.

One of the standout features of these PTO Drive Shafts is the splined end size, which includes 20 teeth. This specific design ensures a secure and stable connection between the shaft and the equipment it powers, minimizing the risk of slippage and mechanical failure. The splined end allows for easy installation and removal, facilitating maintenance and reducing downtime. Combined with the robust shaft diameter, this design enhances the overall durability and longevity of the drive shaft.

The power source for these shafts is the PTO shaft tube, a well-known and trusted mechanism for transferring rotational power from tractors or other power units to attached implements. The PTO shaft tube ensures efficient torque transmission, making these drive shafts ideal for agricultural machinery, industrial equipment, and construction vehicles. Their compatibility with PTO systems highlights their versatility and widespread application across different sectors.

In the automotive industry, these PTO Drive Shafts serve as critical components in various systems, often referred to as automotive shafts. They play a vital role in transmitting power from the engine to the wheels or other mechanical parts. Their design and specifications make them suitable for use as CV drive shafts, which are essential for providing consistent torque to the wheels while allowing for flexible movement in the vehicle’s suspension system. This adaptability ensures smooth driving experience and enhanced vehicle performance.

Furthermore, PTO Drive Shafts are highly valuable in construction and excavation machinery, where heavy loads and harsh operating conditions demand high strength and reliability. The drive shafts are commonly utilized as excavator shafts, where they facilitate the transfer of power within the hydraulic system or other mechanical components of the excavator. Their robust construction and precise engineering enable them to endure the demanding environments of excavation work, ensuring continuous operation and reducing the likelihood of mechanical breakdowns.

Manufactured with high-quality materials and crafted to meet stringent industry standards, these PTO Drive Shafts offer excellent resistance to wear and tear, corrosion, and mechanical fatigue. Their design incorporates a balance of strength and flexibility, which helps absorb shocks and vibrations during operation, protecting connected machinery and enhancing overall system efficiency. The combination of the 100 mm flange diameter, 20 teeth splined end, 50 mm shaft diameter, and 1.5-meter length ensures that these shafts can handle significant power loads while maintaining precise alignment and smooth rotation.

In summary, the PTO Drive Shafts stand out as versatile, durable, and high-performance components suitable for a wide range of applications. Whether used as automotive shafts in vehicles, CV drive shafts ensuring smooth torque transfer, or excavator shafts in heavy machinery, their robust specifications and reliable power source through the PTO shaft tube make them indispensable. These shafts represent an ideal solution for professionals seeking dependable power transmission components that combine strength, precision, and longevity.

Features:

- Product Name: PTO Drive Shafts

- Weight: 10 Kg

- Shaft Diameter: 50 Mm

- Power Source: PTO Shaft Tube

- Flange Thickness: 20 Mm

- Maximum Speed: 1000 Rpm

- Compatible with Drive Shaft Components

- Ideal for use with Drive Shaft Welding Machine

- Suitable for applications involving Cam Shafts

Technical Parameters:

| Shaft Diameter | 50 Mm |

| Flange Diameter | 100 Mm |

| Safety Features | Overload Protection |

| Length | 1.5 Meters |

| Splined End Diameter | 60 Mm |

| Weight | 10 Kg |

| Maximum Torque | 500 Nm |

| Certifications | ISO 9001 |

| Splined End Size | 20 Teeth |

| Power Source | Pto Shaft Tube |

Applications:

The MW PTO Drive Shafts, manufactured in China, are premium quality components designed to deliver reliable performance in various agricultural, industrial, and automotive applications. With a robust shaft diameter of 50 mm and a splined end size of 20 teeth, these forged steel shafts ensure a secure and precise fit, making them ideal for high-torque operations. The use of high-grade forged steel not only enhances durability but also provides excellent resistance to wear and fatigue, which is essential for demanding environments where strength and reliability are paramount.

One of the key application occasions for the MW PTO Drive Shafts is in automotive drive shaft assemblies, where they serve as critical links transmitting power from the engine to the wheels or other driven components. Their design incorporates overload protection as a vital safety feature, preventing damage to machinery and reducing downtime caused by unexpected torque spikes. This makes the MW PTO Drive Shafts particularly suitable for use in heavy-duty vehicles and agricultural machinery that operate under fluctuating load conditions.

In addition to automotive applications, these PTO drive shafts are widely used in agricultural equipment such as tractors, harvesters, and other PTO-driven implements. The combination of the PTO shaft tube as the power source and the high torque shaft screwdriver compatibility ensures smooth and efficient power transmission, improving overall operational efficiency. The ISO 9001 certification further guarantees that each shaft meets stringent quality and performance standards, providing end-users with confidence in the product’s reliability and safety.

Scenarios where the MW PTO Drive Shafts excel include fieldwork involving plowing, tilling, and harvesting, where robust and dependable power transfer is crucial. They are also suitable for industrial machinery requiring precise torque control and durability under continuous use. The forged steel construction allows these shafts to withstand harsh conditions, including exposure to dirt, moisture, and mechanical stress, making them a versatile choice for various drive shaft needs.

Overall, MW PTO Drive Shafts represent a high-performance solution for anyone seeking durable, safe, and efficient drivetrain components. Whether for automotive drive shaft replacements, agricultural machinery upgrades, or industrial equipment maintenance, these forged steel shafts offer unmatched quality and reliability, ensuring optimal performance in every application scenario.

Customization:

MW offers customized PTO Drive Shafts tailored to meet your specific requirements. Manufactured in CHINA, our drive shafts feature a shaft diameter of 50 mm, a splined end diameter of 60 mm, and a splined end length of 50 mm, ensuring precise compatibility with your machinery. The flange diameter is 100 mm, providing robust and reliable connections. As an ISO 9001 certified brand, MW guarantees high-quality Drive Shaft Components designed for durability and optimal performance. Our customized solutions are ideal for Flex Shaft Machines and include expert customization of Gears and Shafts to enhance your equipment's efficiency and longevity.

Support and Services:

Our PTO Drive Shafts are designed to provide reliable and efficient power transmission for a wide range of agricultural and industrial equipment. To ensure optimal performance and longevity, it is important to follow proper installation, maintenance, and safety guidelines.

Installation: Always verify that the PTO drive shaft is the correct size and type for your equipment. Ensure all connections are secure and properly aligned to prevent undue stress on the components. Use the recommended torque settings for fasteners and check for any signs of wear or damage before operation.

Maintenance: Regularly inspect the PTO drive shaft for signs of wear, corrosion, or damage. Lubricate all grease fittings according to the manufacturer’s recommendations to reduce friction and prevent premature failure. Replace any worn or damaged parts promptly to maintain safety and performance.

Safety: Never operate equipment with a damaged or improperly installed PTO drive shaft. Always use the protective guards provided to prevent accidental contact with rotating components. Follow all safety instructions outlined in the equipment’s user manual and wear appropriate personal protective equipment when servicing the drive shaft.

Technical Support: For troubleshooting assistance, parts replacement, or technical inquiries, refer to the product manual or visit our website for detailed guides and FAQs. Our technical support team is available to help you maximize the performance and reliability of your PTO drive shaft.

Services: We offer a range of services including repair, replacement parts, and routine maintenance programs to ensure your PTO drive shaft operates efficiently. Contact your local authorized service center to schedule service or obtain genuine replacement components.

Packing and Shipping:

Our PTO Drive Shafts are carefully packaged to ensure maximum protection during transit. Each shaft is securely wrapped with protective materials to prevent damage and corrosion. The packaging is designed to withstand rough handling and environmental factors, ensuring the product arrives in perfect condition.

We offer reliable shipping options with tracking available for all orders. Depending on your location, shipping times may vary, but we strive to deliver your PTO Drive Shafts promptly and efficiently. For bulk orders, we provide customized packaging and shipping solutions to meet your specific needs.

FAQ:

Q1: What brand manufactures the PTO Drive Shafts?

A1: The PTO Drive Shafts are manufactured by the brand MW.

Q2: Is there a specific model number for the PTO Drive Shafts?

A2: No, the PTO Drive Shafts do not have a specific model number.

Q3: Where are the MW PTO Drive Shafts made?

A3: The MW PTO Drive Shafts are made in China.

Q4: What applications are MW PTO Drive Shafts suitable for?

A4: MW PTO Drive Shafts are typically used in agricultural machinery, lawn equipment, and other machinery requiring power transmission from a tractor to an implement.

Q5: How can I ensure the PTO Drive Shaft is compatible with my equipment?

A5: To ensure compatibility, check the shaft dimensions and connection types of your equipment and compare them with the specifications provided by MW or consult with the supplier directly.

pto shaft,

tractor pto shaft

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Power Transmission PTO Drive Shafts For Rotary Tiller , power take off shaft

-

Agricultural Tractor PTO Drive Shafts replacement / custom made drive shafts

-

Professiona Farm Cardan PTO Drive Shafts with Overruning Clutch

-

Custom Planter Machine PTO Drive Shafts Ratchet Torque Limiter driving shaft

-

Auto parts flexible drive shaft PTO / Cardan Shaft for Agriculture Rotavator

-

4x4 Power Take off PTO Drive Shafts Shear Bolt Torque Limiter