|

|

|

|

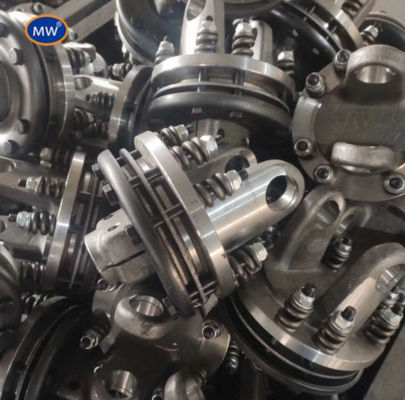

60 Mm Splined End Diameter High Torque Shaft Screwdriver 10 Kg Designed for Torque Transmission and Long Term Industrial

| Weight: | 10 Kg | Length: | 1.5 Meters |

|---|---|---|---|

| Flange Diameter: | 100 Mm | Splined End Size: | 20 Teeth |

| Maximum Torque: | 500 Nm | Splined End Diameter: | 60 Mm |

| Power Source: | Pto Shaft Tube | Safety Features: | Overload Protection |

Product Description:

The PTO Drive Shafts are precision-engineered components designed to efficiently transfer power in agricultural, industrial, and mechanical applications. These shafts are crucial for connecting the power take-off (PTO) of a tractor or motor to various implements, ensuring smooth and reliable operation. The primary power source for these drive shafts is the PTO shaft tube, which serves as the core structure, providing strength and rigidity while allowing for efficient torque transmission.

One of the standout features of this PTO Drive Shaft is its robust safety mechanism. Equipped with advanced overload protection, the shaft is designed to prevent damage caused by unexpected torque spikes or mechanical overloads. This safety feature not only extends the lifespan of the drive shaft but also protects the connected machinery from potential failures, ensuring uninterrupted performance and reducing downtime.

The drive shaft’s splined end diameter measures 60 mm, a specification that ensures compatibility with a wide range of tractors and implements. The splined end is crucial for secure attachment and effective torque transfer, minimizing slippage and wear. This design also simplifies installation and removal, making maintenance more straightforward for operators and technicians.

With a length of 1.5 meters, this PTO Drive Shaft is versatile enough for various configurations and applications. Whether used in compact machinery or larger agricultural equipment, the length provides the necessary reach while maintaining structural integrity. The hollow shaft motor design incorporated into the PTO Drive Shaft offers additional benefits by reducing weight without compromising strength. This hollow construction allows for easier handling and installation, contributing to overall efficiency and user convenience.

Performance-wise, the PTO Drive Shaft is capable of operating at a maximum speed of 1000 RPM. This high-speed capability ensures that the shaft can handle demanding tasks and high-power transmissions with ease. The ability to operate smoothly at such speeds is essential for modern agricultural and industrial equipment that require both precision and power.

Additionally, the PTO Drive Shaft integrates several key components that enhance its functionality. The drive shaft pin plays a vital role in securing the shaft to the implement or power source, ensuring stable and reliable operation. This pin is engineered to withstand significant stress, providing a secure connection even under heavy loads and rigorous working conditions.

Another important aspect of the PTO Drive Shaft is its role as a drive axle shaft in various machinery. Acting as the intermediary component that transmits rotational force from the power source to the working parts, it is essential for the overall drivetrain system. The reliability and durability of this drive axle shaft directly influence the efficiency and longevity of the equipment it powers.

Overall, the PTO Drive Shaft combines robust engineering, safety features, and versatile design to meet the demanding requirements of modern machinery. Its combination of a 60 mm splined end diameter, 1.5-meter length, overload protection, and a hollow shaft motor structure makes it an indispensable component in power transmission systems. Whether used in agricultural tractors, industrial machines, or other PTO-driven equipment, this drive shaft ensures efficient, safe, and reliable operation, making it a trusted choice for professionals and manufacturers alike.

Features:

- Product Name: PTO Drive Shafts

- Shaft Diameter: 50 mm

- Splined End Length: 50 mm

- Maximum Torque: 500 Nm

- Power Source: PTO Shaft Tube

- Certified with ISO 9001 for quality assurance

- Compatible with Excavator Drive Sprockets

- Includes durable Drive Shaft Pin for secure connections

- Designed as a High Torque Shaft to withstand heavy-duty applications

Technical Parameters:

| Material | Steel |

| Splined End Size | 20 Teeth |

| Maximum Speed | 1000 Rpm |

| Safety Features | Overload Protection |

| Length | 1.5 Meters |

| Flange Diameter | 100 Mm |

| Keyway Size | 10 Mm |

| Flange Thickness | 20 Mm |

| Weight | 10 Kg |

| Maximum Torque | 500 Nm |

Applications:

The MW PTO Drive Shafts, proudly manufactured in China, are engineered to meet the highest standards of performance and durability. These drive shafts are designed with a splined end diameter of 60 mm and a flange diameter of 100 mm, featuring a keyway size of 10 mm to ensure a secure and precise fit in various machinery applications. With ISO 9001 certification, MW guarantees that every PTO drive shaft adheres to strict quality control measures, offering reliability and long-lasting service.

The PTO Drive Shafts by MW are ideal for a wide range of industrial and agricultural applications, particularly where power transmission efficiency and safety are paramount. One of the primary application occasions includes the integration with extruder shafts in plastic and rubber extrusion machines. These high-torque environments demand robust and consistent operation, which MW PTO drive shafts deliver through their superior construction and overload protection safety features. This overload protection mechanism safeguards the equipment from damage due to unexpected torque spikes, ensuring operational safety and minimizing downtime.

Another critical application scenario for MW PTO Drive Shafts is in automotive manufacturing and repair, where they serve as reliable automotive shafts. These shafts are essential components in transmitting power within various automotive systems, including drive trains and auxiliary equipment. The precise dimensions, including the 60 mm splined end and 10 mm keyway, facilitate seamless integration with cam shafts and other automotive parts, promoting efficient power transfer and reducing wear and tear.

Moreover, MW PTO Drive Shafts are extensively used in cam shafts applications, where accurate rotational movement and torque transmission are crucial. Their robust design and ISO 9001 certification make them suitable for heavy-duty machinery that requires consistent performance under demanding conditions. Whether in agricultural machinery, industrial equipment, or automotive systems, MW PTO Drive Shafts provide dependable service with enhanced safety due to their built-in overload protection.

In summary, MW PTO Drive Shafts are versatile components suitable for extruder shaft setups, cam shaft assemblies, and automotive shaft applications. Their precise engineering, adherence to international quality standards, and advanced safety features make them indispensable in scenarios requiring reliable power transmission and operational safety. Whether in manufacturing plants, automotive workshops, or agricultural fields, MW PTO Drive Shafts stand out as a trusted solution for efficient and safe machinery operation.

Customization:

MW offers customizable PTO Drive Shafts designed to meet your specific requirements. Manufactured in CHINA, our drivetrain shafts provide reliable performance with a maximum torque capacity of 500 Nm. The PTO Drive Shaft features a power source based on a PTO shaft tube, ensuring efficient power transmission. With a shaft diameter of 50 mm and a splined end length of 50 mm, these shafts are engineered for precision and durability. The keyway size of 10 mm allows for secure fitting and compatibility with various machinery. Our customization services also include axle shaft forging to enhance strength and longevity, making them ideal for CV axle shaft applications. Trust MW for high-quality, customized drivetrain shaft solutions tailored to your needs.

Support and Services:

Our PTO Drive Shafts are designed to deliver reliable power transmission for a variety of agricultural and industrial machinery. To ensure optimal performance and longevity, it is important to follow proper installation, maintenance, and safety guidelines.

If you experience any issues with your PTO Drive Shaft, please refer to the user manual for troubleshooting tips. Regular inspection for wear, lubrication of moving parts, and checking for proper alignment can prevent most common problems.

We offer comprehensive technical support to assist you with product selection, installation advice, and maintenance procedures. Our team of experts is available to help diagnose issues and recommend the best solutions to keep your equipment running smoothly.

For maintenance, always use the recommended lubricants and replacement parts to avoid damage and ensure safety. Never operate the drive shaft at speeds or torque levels beyond the specified limits.

Safety is paramount when working with PTO Drive Shafts. Always ensure that all guards are in place during operation, and never attempt to adjust or repair the shaft while the machinery is running.

To extend the life of your PTO Drive Shaft, store it in a clean, dry place when not in use, and protect it from corrosion and physical damage.

Our services include installation support, repair guidance, and availability of genuine replacement parts to maintain the integrity and performance of your PTO Drive Shafts.

For detailed technical documentation and service manuals, please refer to the resources provided with your product or visit our official website.

Packing and Shipping:

Our PTO Drive Shafts are carefully packaged to ensure maximum protection during transit. Each shaft is wrapped in protective materials and securely placed in a sturdy box to prevent any damage.

We offer reliable shipping options with tracking to ensure your PTO Drive Shafts arrive on time and in perfect condition. Shipping times may vary depending on your location, but we strive to dispatch orders within 1-2 business days.

For international orders, please note that additional customs fees or import taxes may apply. We recommend checking with your local customs office for more information.

If you have any special packaging or shipping requirements, please contact our customer service team, and we will be happy to assist you.

FAQ:

Q: What brand manufactures the PTO Drive Shafts?

A: The PTO Drive Shafts are manufactured by the brand MW.

Q: What is the model number of the MW PTO Drive Shafts?

A: The MW PTO Drive Shafts do not have a specific model number.

Q: Where are the MW PTO Drive Shafts made?

A: The MW PTO Drive Shafts are made in China.

Q: What applications are MW PTO Drive Shafts suitable for?

A: MW PTO Drive Shafts are suitable for use in agricultural machinery, industrial equipment, and any application requiring power transmission via a PTO shaft.

Q: Are the MW PTO Drive Shafts compatible with standard PTO systems?

A: Yes, MW PTO Drive Shafts are designed to be compatible with standard PTO systems, ensuring easy installation and reliable performance.

pto shaft,

tractor pto shaft

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Power Transmission PTO Drive Shafts For Rotary Tiller , power take off shaft

-

Agricultural Tractor PTO Drive Shafts replacement / custom made drive shafts

-

Professiona Farm Cardan PTO Drive Shafts with Overruning Clutch

-

Custom Planter Machine PTO Drive Shafts Ratchet Torque Limiter driving shaft

-

Auto parts flexible drive shaft PTO / Cardan Shaft for Agriculture Rotavator

-

4x4 Power Take off PTO Drive Shafts Shear Bolt Torque Limiter