|

|

|

|

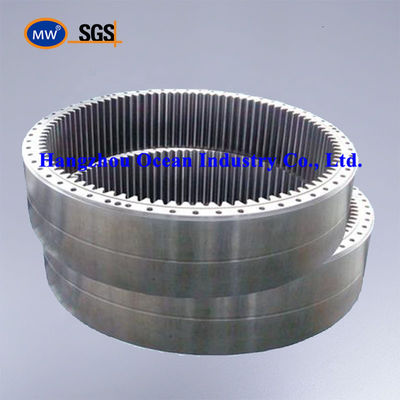

Industrial Machinery Gears and Pinions Featuring Tolerance 00105mm Customized Surface Finish Ground Ideal for Heavy Duty Applications

| Surface Finish: | Ground | Shape: | Round |

|---|---|---|---|

| Tolerance: | 0.01-0.05mm Or Customized | Tooth Profile: | Helical Gear |

| Processing: | CNC Machining | Heat Treatment: | Carburizing And Quenching |

| Compatibility: | Can Be Used With Various Gear Systems | Material: | Steel |

Product Description:

The Gears and Pinions product is a high-quality mechanical component designed to meet the demanding requirements of modern engineering applications. Manufactured using advanced CNC machining technology, these gears ensure exceptional precision and reliability. CNC machining allows for meticulous control over the dimensions and finish of each gear, resulting in a product that consistently meets tight tolerance levels, typically ranging from 0.01 to 0.05mm, or customized according to specific customer needs. This high level of precision is crucial for applications where exact gear meshing and smooth power transmission are paramount.

Constructed from premium-grade steel, the Gears and Pinions offer outstanding durability and strength. Steel is chosen for its excellent wear resistance, toughness, and ability to withstand high loads without deformation. This makes these gears ideal for heavy-duty applications where high load capacity is essential. Whether used in automotive, industrial machinery, or other mechanical systems, the steel material ensures long service life and consistent performance under stress.

One of the defining features of this product is its right-hand direction design. Right-hand gears are commonly used in many mechanical systems to transmit motion and power efficiently. The directionality ensures compatibility with a wide range of gear assemblies, including those involving engine gear configurations and complex gear trains. Proper directionality is vital for maintaining the correct rotational direction and torque transfer, which directly impacts the overall efficiency and functionality of the machinery.

These Gears and Pinions are integral components in systems involving gears and shafts. The seamless interaction between gears and shafts is fundamental to the effective transmission of mechanical power. By focusing on the precision and quality of these gears, the product ensures optimal engagement with shafts, reducing wear and minimizing backlash. This results in smoother operation, less noise, and improved mechanical efficiency, which are critical factors in high-performance equipment.

Moreover, the product’s high load capacity makes it suitable for a variety of challenging applications. Whether incorporated into an engine gear assembly or other gear-driven mechanisms, these gears can handle significant forces without compromising structural integrity. This capability is essential in environments where mechanical components are subjected to continuous heavy loads, such as automotive transmissions, industrial gearboxes, and heavy machinery.

In addition to its robust physical properties, this product exemplifies high precision gears technology. High precision gears are crucial in applications requiring accurate motion control and minimal mechanical play. The tight tolerance range achievable through CNC machining ensures that each gear tooth is manufactured to exact specifications, promoting efficient power transfer and reducing the risk of premature wear or failure. This precision contributes to the overall reliability and longevity of the mechanical system.

In summary, the Gears and Pinions product stands out as a premium solution for industries demanding high-performance and durable gears. Its manufacturing process involving CNC machining, combined with a steel material composition and a tolerance range of 0.01 to 0.05mm (or customized), guarantees exceptional accuracy and strength. Designed with a right-hand direction and capable of bearing high loads, these gears seamlessly integrate with gears and shafts to deliver smooth, efficient, and reliable power transmission. Whether utilized as an engine gear or in other mechanical assemblies, these high precision gears represent a dependable choice for enhancing the performance and longevity of your machinery.

Features:

- Product Name: Gears and Pinions

- Tooth Profile: Helical Gear

- Direction: Right Hand

- Surface Finish: Ground

- Pitch: Standard

- Application: Industrial Machinery

- Ideal for Gear Mold applications ensuring precision and durability

- Perfect component for Gear Box Assembly in various industrial settings

- Designed to meet the demands of Gear Mold manufacturing processes

Technical Parameters:

| Compatibility | Can Be Used With Various Gear Systems |

| Pitch | Standard |

| Module | 1-10 |

| Material | Steel |

| Surface Finish | Ground |

| Size | Various Sizes Available |

| Load Capacity | High |

| Application | Industrial Machinery |

| Tooth Profile | Helical Gear |

| Processing | CNC Machining |

Applications:

The MW Gears and Pinions, manufactured in China, are essential components widely used in various industrial machinery applications. Available in various sizes, these gears feature a helical gear tooth profile that ensures smooth and efficient power transmission. The round shape of the gears, combined with advanced heat treatment processes such as carburizing and quenching, guarantees exceptional durability, wear resistance, and long service life, making them ideal for demanding operating conditions.

These MW gears and pinions are commonly utilized as critical gear box components within numerous mechanical systems. Their precise design and robust construction allow them to seamlessly integrate into gear box assemblies, ensuring reliable performance and optimal torque transmission. Whether used in large-scale industrial equipment or specialized machinery, these gears contribute significantly to the overall efficiency and functionality of the gear box assembly.

In addition to industrial machinery, MW gears and pinions are also suitable for use as car gearbox parts. Their helical tooth profile reduces noise and vibration, enhancing the driving experience by providing smooth gear shifts and consistent power delivery. The carburizing and quenching heat treatment enhances the hardness of the gear surface, which is crucial for automotive applications where gears must withstand high loads and rapid changes in speed.

The versatility of MW gears and pinions is reflected in their ability to meet the diverse demands of various gear box components in both industrial and automotive settings. Their superior quality and reliable performance make them a preferred choice for engineers and manufacturers seeking durable and efficient gear solutions. With MW’s commitment to excellence and precision manufacturing, these gears and pinions stand out as essential parts in the assembly of gearboxes, contributing to the seamless operation of machinery and vehicles alike.

In summary, MW's gears and pinions offer a combination of advanced material treatment, precise helical tooth design, and adaptability to various sizes, making them indispensable gear box components for industrial machinery and car gearbox parts. Their role in gear box assembly ensures enhanced mechanical performance, durability, and efficiency across a wide range of applications.

Customization:

MW offers professional product customization services for Gears and Pinions, designed to meet the specific needs of your gear box assembly. Manufactured in CHINA, our gears are compatible with various gear systems, ensuring versatile application across different industries. Utilizing advanced CNC machining processes, we achieve precise tolerances ranging from 0.01-0.05mm or customized according to your requirements. Our gears feature a high-quality ground surface finish and a helical gear tooth profile, providing excellent performance and durability. Whether you need gear forgings or gears for other industries, MW is dedicated to delivering reliable and tailored solutions for all your gear customization needs.

Support and Services:

Our Gears and Pinions product is supported by a dedicated technical team committed to ensuring optimal performance and longevity. We offer comprehensive technical support services including installation guidance, maintenance tips, troubleshooting assistance, and customization advice to meet your specific requirements. Our experts are equipped to provide detailed product information, compatibility assessments, and usage recommendations to help you maximize efficiency and reliability. Additionally, we provide repair and replacement services to minimize downtime and extend the service life of your gears and pinions. For ongoing support, we also offer training sessions and resource materials designed to enhance your understanding and handling of our products.

Packing and Shipping:

Our Gears and Pinions are carefully packaged to ensure maximum protection during transit. Each component is individually wrapped in protective material to prevent damage and corrosion. The products are then securely placed in sturdy boxes with appropriate cushioning to absorb shocks and vibrations.

For shipping, we use reliable carriers that offer tracking and insurance options to guarantee safe delivery. We handle all logistics with care to ensure your Gears and Pinions arrive on time and in perfect condition, ready for immediate use in your machinery.

FAQ:

Q1: What brand manufactures these gears and pinions?

A1: These gears and pinions are manufactured by the brand MW.

Q2: What is the model number of these gears and pinions?

A2: These gears and pinions do not have a specific model number.

Q3: Where are these gears and pinions made?

A3: These gears and pinions are made in China.

Q4: What materials are used to make MW gears and pinions?

A4: MW gears and pinions are typically made from high-quality steel or alloy to ensure durability and precision.

Q5: Are these gears and pinions suitable for industrial applications?

A5: Yes, MW gears and pinions are designed to meet the demands of various industrial applications, offering reliable performance.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

With Teeth Hardened Carbon Steel Crush 1.75 Gears And Pinions

-

Helical Spur Bevel JIS Class 0 Crown Wheel Pinion

-

Planetary Helical DIN Class 4 Gears And Pinions

-

Transmission Harden Steel EX60-5 Ring And Pinion Gears

-

Speed Reducer Bronze Steel C45 Worm Wheel Gear

-

Auto Parts Left Hand 1.25 Crown Wheel And Pinion Gear