|

|

|

|

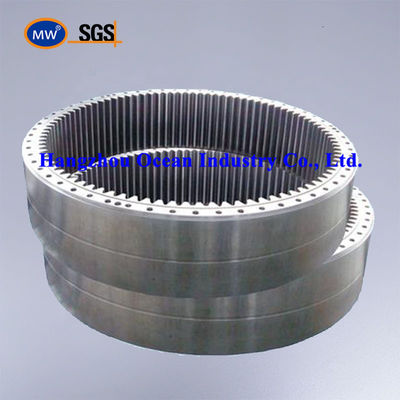

Industrial Machinery Car Gearbox Parts Module 1 to 10 Durable Components for Transmission Systems and Vehicle Gear Operation

| Tooth Profile: | Helical Gear | Direction: | Right Hand |

|---|---|---|---|

| Heat Treatment: | Carburizing And Quenching | Size: | Various Sizes Available |

| Processing: | CNC Machining | Load Capacity: | High |

| Pitch: | Standard | Shape: | Round |

Product Description:

The Gears and Pinions product is a meticulously engineered component designed to meet the rigorous demands of industrial machinery applications. Featuring a classic round shape, these gears are crafted to ensure optimal performance and durability in a variety of mechanical systems. Their robust construction allows them to handle high load capacities, making them ideal for use in heavy-duty environments where reliability and strength are paramount.

Manufactured through advanced CNC machining processes, these gears and pinions exhibit exceptional precision and consistency. CNC machining ensures that each gear tooth is accurately formed, contributing to smooth and efficient power transmission. This high level of precision is critical in applications where even minor deviations can lead to significant mechanical failures or decreased efficiency.

One of the key characteristics of these gears is their right-hand direction, which aligns with the operational requirements of many industrial machines. This directional specification ensures compatibility and seamless integration with existing systems, reducing the need for modifications and facilitating easier installation. The right-hand orientation also supports the effective transfer of torque, enhancing the overall mechanical performance of the machinery in which they are employed.

These gears and pinions are widely utilized in various sectors within the industrial machinery field. Their versatility extends beyond traditional applications, making them a preferred choice in gears for other industries as well. Whether incorporated into conveyor systems, heavy-duty engines, or complex gear shafts, these components deliver reliable power transmission and long service life. Their adaptability to different industrial setups underscores their importance as a fundamental element in mechanical design.

In the realm of engine gear components, these gears and pinions stand out for their ability to withstand high stress and continuous operation. Engine gear applications demand components that can endure significant forces while maintaining precise timing and synchronization. The high load capacity of these gears makes them particularly suitable for such demanding roles, contributing to the efficient functioning of internal combustion engines and other powertrain systems.

Additionally, the integration of these gears into gear shafts enhances the structural integrity and performance of the overall assembly. The precise fit and finish achieved through CNC machining allow for smooth meshing and reduced wear, which in turn extends the lifespan of the gear shafts and reduces maintenance requirements. This synergy between gears and gear shafts is crucial in maintaining the reliability of industrial equipment and minimizing downtime.

In summary, the Gears and Pinions product is an essential component for industrial machinery, offering a combination of high load capacity, right-hand directional design, and CNC machining precision. Its round shape and robust construction make it suitable for a wide range of applications, including engine gear assemblies and gear shafts. Moreover, its adaptability to gears for other industries highlights its versatility and critical role in modern mechanical systems. Choosing these gears ensures enhanced performance, durability, and efficiency in demanding industrial environments.

Features:

- Product Name: Gears and Pinions

- Direction: Right Hand

- Tolerance: 0.01-0.05mm or Customized

- Load Capacity: High

- Module Range: 1-10

- Shape: Round

- Manufactured using precision Gear Forgings

- Ideal for use as Car Gearbox Parts

- High-quality Gears designed for durability and performance

Technical Parameters:

| Hardness | HRC 45-55 |

| Module | 1-10 |

| Direction | Right Hand |

| Tooth Profile | Helical Gear |

| Processing | CNC Machining |

| Pitch | Standard |

| Application | Industrial Machinery |

| Heat Treatment | Carburizing And Quenching |

| Compatibility | Can Be Used With Various Gear Systems |

| Tolerance | 0.01-0.05mm Or Customized |

Applications:

The MW brand Gears and Pinions, manufactured in China, are precision-engineered components designed to meet the highest standards of quality and performance. With a hardness rating of HRC 45-55, these gears exhibit exceptional wear resistance and durability, making them ideal for demanding mechanical applications. The tolerance range of 0.01-0.05mm, or customized according to specific requirements, ensures precise fitting and smooth operation in various machinery.

Thanks to their standard pitch and round shape, MW Gears and Pinions are versatile and suitable for a wide range of gear systems. The use of advanced CNC machining processes guarantees accuracy and consistency, which is critical in applications where reliability and efficiency are paramount. These attributes make them the preferred choice for industries that rely heavily on gear components.

MW Gears and Pinions find extensive application occasions and scenarios across different sectors. In automotive manufacturing, these gears are used in transmissions, differential systems, and engine components, where high precision and strength are essential. The superior hardness and tolerance control contribute to the longevity and reliability of vehicles, reducing maintenance costs and downtime.

In industrial machinery, MW gear forgings and gear mold components are integral to the operation of heavy-duty equipment, including conveyors, crushers, and milling machines. The precision and durability of these gears enable the smooth transfer of power and motion, enhancing the overall efficiency of production lines. Gear mold technology used in the creation of these parts ensures consistent quality and enables customization for specialized industrial needs.

Additionally, MW Gears and Pinions are widely used in robotics and automation systems, where exact movements and synchronization are crucial. The combination of CNC machining and stringent tolerance standards ensures that these gears perform reliably under various load conditions and speeds. This makes them indispensable in modern automated manufacturing and assembly lines.

Furthermore, the aerospace industry benefits from the high-quality gear components produced by MW, where safety and precision are non-negotiable. The gears manufactured through advanced gear mold processes ensure optimal performance in aircraft engines and control systems.

In summary, MW Gears and Pinions, with their robust hardness, precise tolerance, and CNC machining excellence, are suitable for a broad spectrum of applications. From automotive and industrial machinery to robotics and aerospace, these gears deliver reliable performance and durability, supported by expert gear forgings and gear mold technologies. Their origin in China ensures cost-effective manufacturing without compromising quality, making them a trusted choice worldwide.

Customization:

MW offers high-quality Gears and Pinions made from durable steel with a precision ground surface finish. Our products, manufactured in China, are designed with a module range of 1-10 to ensure compatibility with various gear systems. Utilizing advanced CNC machining processes, our gears provide excellent performance and reliability, making them ideal for Gear Box Assembly applications. Whether you need Gear Forgings or Car Gearbox Parts, MW's Gears and Pinions deliver superior strength and precision to meet your customization requirements.

Support and Services:

Our Gears and Pinions product line is supported by a dedicated technical support team committed to ensuring optimal performance and reliability. We offer comprehensive installation guidance, maintenance tips, and troubleshooting assistance to help you maximize the lifespan and efficiency of your gears and pinions.

Our services include detailed product documentation, application engineering support, and customized solutions tailored to your specific requirements. Whether you need help selecting the right gear type, understanding load capacities, or integrating our components into your machinery, our experts are here to assist you every step of the way.

We also provide training sessions and technical workshops to equip your team with the necessary knowledge and skills for proper handling and upkeep of gears and pinions. Additionally, our quality assurance processes ensure that every product meets rigorous industry standards for durability and performance.

For ongoing support, we offer maintenance contracts and inspection services designed to detect and address potential issues before they impact your operations. Trust our technical support and services to keep your mechanical systems running smoothly and efficiently.

Packing and Shipping:

Our Gears and Pinions are carefully packaged to ensure maximum protection during transit. Each gear and pinion is individually wrapped with protective material to prevent damage and corrosion. They are then securely placed in sturdy, cushioned boxes designed to withstand shipping stresses.

We ship our products using reliable carriers with tracking options available for all orders. Depending on your location and shipping preference, delivery times may vary. Expedited shipping services are also offered for urgent requirements. Upon shipment, you will receive a confirmation email with tracking details to monitor your package until it arrives safely at your doorstep.

FAQ:

Q: What brand manufactures the Gears and Pinions?

A: The Gears and Pinions are manufactured by the brand MW.

Q: Do the MW Gears and Pinions come with a model number?

A: No, the MW Gears and Pinions do not have a specific model number.

Q: Where are the MW Gears and Pinions made?

A: These gears and pinions are made in China.

Q: What materials are used in the MW Gears and Pinions?

A: The MW Gears and Pinions are typically made from high-quality steel to ensure durability and performance.

Q: Are the MW Gears and Pinions compatible with standard machinery?

A: Yes, MW Gears and Pinions are designed to be compatible with a wide range of standard machinery applications.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

With Teeth Hardened Carbon Steel Crush 1.75 Gears And Pinions

-

Helical Spur Bevel JIS Class 0 Crown Wheel Pinion

-

Planetary Helical DIN Class 4 Gears And Pinions

-

Transmission Harden Steel EX60-5 Ring And Pinion Gears

-

Speed Reducer Bronze Steel C45 Worm Wheel Gear

-

Auto Parts Left Hand 1.25 Crown Wheel And Pinion Gear