|

|

|

|

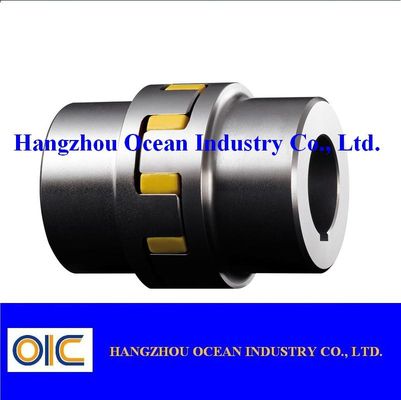

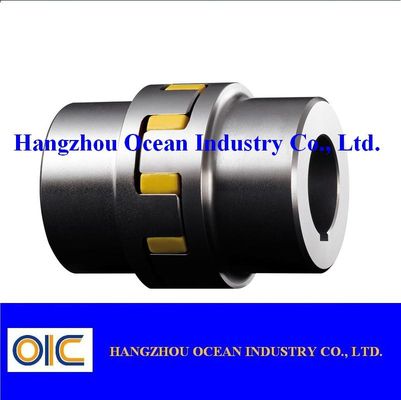

Bolt-on Flexible Coupling Parts Designed for High Corrosion Resistance Ensuring Durable Performance in Harsh Environments

| Max Torque: | 500 Nm | Corrosion Resistance: | High |

|---|---|---|---|

| Max Speed: | 10,000 RPM | Torsional Stiffness: | High |

| Misalignment Capacity: | ±3° | Material: | Stainless Steel |

| Certifications: | ISO 9001, CE | Color: | Silver |

Product Description:

Flexible couplings are essential components widely used in industrial machinery to connect two shafts together, allowing for the transmission of torque while accommodating misalignment and reducing vibration. Our range of flexible couplings, crafted from high-quality stainless steel, offers exceptional durability and performance in demanding industrial environments. Designed to withstand temperatures up to 200°C, these couplings are suitable for a broad spectrum of applications where reliability and flexibility are paramount.

One of the most popular types within this category is the Flexible Jaw Coupling, known for its ability to absorb shock loads and dampen vibrations effectively. The unique jaw design provides a secure yet flexible connection between shafts, making it ideal for applications where slight misalignments or axial movements occur. This coupling type helps protect connected equipment from premature wear and tear, thereby extending the operational life of machinery and reducing maintenance costs.

In addition to the Flexible Jaw Coupling, our product lineup includes the Flexible Shaft Coupling, which is specifically engineered to accommodate angular, parallel, and axial misalignments. This versatility ensures smooth power transmission even in complex industrial setups where precision alignment is challenging. Both types of couplings are manufactured using stainless steel, which offers excellent corrosion resistance, mechanical strength, and longevity, especially in harsh industrial conditions involving exposure to chemicals or moisture.

Our flexible couplings are available in various sizes to meet the diverse requirements of different machinery and industrial processes. Whether you are working with small precision equipment or large heavy-duty machines, you can find a coupling size that perfectly matches your shaft dimensions. This size versatility ensures optimum fit and function, enhancing the overall efficiency and reliability of your machinery.

The temperature range capability of up to 200°C makes these flexible couplings suitable for applications involving elevated temperatures, such as in heating systems, chemical processing, or manufacturing lines where thermal expansion and contraction are factors to consider. The stainless steel material maintains its mechanical properties even under these high-temperature conditions, ensuring consistent performance without deformation or loss of flexibility.

Installation of our flexible couplings is straightforward, and their robust design requires minimal maintenance, making them an attractive choice for industrial engineers and maintenance professionals. The flexibility inherent in both Flexible Jaw Coupling and Flexible Shaft Coupling types helps reduce the transmission of shock loads and vibrations to connected components, safeguarding motors, pumps, compressors, and other machinery elements from damage.

In summary, our range of flexible couplings offers a combination of strength, flexibility, and durability tailored to meet the demanding needs of industrial machinery applications. The use of stainless steel as the primary material ensures excellent corrosion resistance and mechanical stability, while the capability to operate at temperatures up to 200°C broadens the scope of applications. With various sizes available, our flexible couplings provide a reliable solution for connecting shafts with misalignment issues, reducing backlash, and improving overall system performance.

Whether you require the shock-absorbing properties of the Flexible Jaw Coupling or the versatile alignment compensation of the Flexible Shaft Coupling, our product line delivers quality and dependability. Invest in our flexible couplings to enhance the longevity and efficiency of your industrial machinery, minimizing downtime and maintenance costs while ensuring smooth and reliable power transmission.

Features:

- Product Name: Flexible Couplings

- Vibration Damping: Yes, ensuring smooth and efficient operation

- Temperature Range: Up To 200°C, suitable for high-temperature applications

- Size: Various Sizes Available to fit diverse machinery requirements

- Corrosion Resistance: High, providing durability in harsh environments

- Certifications: ISO 9001, CE certified for quality and safety standards

- Includes types such as GR Coupling and Grid Spring Coupling

- Compatible with Hydraulic Hose Couplings for versatile connectivity

Technical Parameters:

| Max Torque | 500 Nm |

| Certifications | ISO 9001, CE |

| Vibration Damping | Yes |

| Misalignment Capacity | ±3° |

| Connection Type | Flange |

| Application | Industrial Machinery |

| Corrosion Resistance | High |

| Installation Method | Bolt-on |

| Material | Stainless Steel |

| Type | Flexible |

Applications:

The MW Flexible Couplings, proudly manufactured in China, are engineered to meet the demanding requirements of various industrial applications. These high-performance couplings are designed to provide reliable and efficient torque transmission while accommodating misalignment between connected shafts. With a robust construction made from premium stainless steel, MW Flexible Couplings offer excellent durability and resistance to corrosion, ensuring long service life even in harsh environments.

One of the standout features of MW Flexible Couplings is their ability to operate within a wide temperature range of up to 200°C, making them suitable for use in high-temperature environments such as automotive engines, industrial machinery, and power generation equipment. The high torsional stiffness of these couplings ensures minimal angular displacement under load, which contributes to precise and stable power transmission. This attribute is particularly valuable in applications where maintaining alignment and minimizing backlash is critical.

MW’s Aluminum Flexible Coupling variants combine lightweight design with the inherent flexibility needed to absorb shocks and vibrations, enhancing the overall performance of mechanical systems. The vibration damping capability of these couplings reduces noise and wear on connected components, promoting smoother operation and extending the lifespan of machinery. This makes them ideal for use in precision equipment, robotics, and automation systems where vibration control is essential.

The installation method for MW Flexible Couplings is bolt-on, which simplifies the assembly and maintenance processes. This user-friendly approach allows for quick and secure installation, reducing downtime and labor costs. These couplings are widely used across a range of industries, including manufacturing, aerospace, marine, and renewable energy sectors, where dependable coupling solutions are required to handle varying loads and environmental conditions.

In summary, MW Flexible Couplings represent a versatile and reliable solution for multiple coupling applications. Whether you require a stainless steel coupling with high torsional stiffness for heavy-duty machinery or an Aluminum Flexible Coupling for lightweight, vibration-damped applications, MW provides a coupling product that meets stringent performance standards. Their high temperature tolerance, robust material construction, and efficient bolt-on installation make them a preferred choice for engineers and maintenance professionals worldwide.

Customization:

MW offers comprehensive product customization services for our Flexible Couplings, designed to meet diverse industrial needs. Our flexible couplings, including GR Coupling, Flexible Metal Coupling, and Flexible Rubber Coupling, are manufactured with high corrosion resistance to ensure durability and long service life. Originating from CHINA, these couplings come in various sizes to suit different applications, supporting a maximum torque of up to 500 Nm and a maximum speed of 10,000 RPM. Whether you require a flexible coupling for precise torque transmission or vibration damping, MW provides tailored solutions to optimize performance and reliability. Contact us to customize your flexible coupling to the exact specifications required for your project.

Support and Services:

Our Flexible Couplings are designed to provide reliable and efficient torque transmission while accommodating misalignment between connected shafts. To ensure optimal performance and longevity of your Flexible Couplings, please follow the installation, maintenance, and troubleshooting guidelines outlined in the product manual.

Installation: Proper alignment during installation is critical. Ensure that the coupling hubs are mounted securely on the shafts with the correct keyway and that the bolts are tightened to the specified torque values. Avoid excessive axial or radial loads that exceed the coupling’s design specifications.

Maintenance: Regular inspection is recommended to check for wear, corrosion, or any signs of damage. Lubricate the coupling components as specified in the maintenance instructions. Replace worn or damaged parts promptly to prevent operational failures.

Troubleshooting: Common issues such as vibration, noise, or overheating may indicate misalignment, imbalance, or inadequate lubrication. Verify alignment using precision tools and adjust as necessary. Ensure that the coupling is clean and free from debris. If problems persist, consult the detailed troubleshooting section in the product documentation.

For detailed technical support, including installation assistance, maintenance schedules, and troubleshooting advice, please refer to the official product manual or visit our technical support website.

Packing and Shipping:

Our Flexible Couplings are carefully packaged to ensure maximum protection during transit. Each coupling is individually wrapped in protective material and securely placed in a sturdy cardboard box to prevent any damage.

For bulk orders, couplings are packed in reinforced cartons with adequate cushioning to withstand handling and shipping stresses.

We offer various shipping options to meet your delivery requirements, including standard, expedited, and freight services. All shipments are tracked, and you will receive a confirmation and tracking number once your order has been dispatched.

Our packaging and shipping processes comply with international standards to guarantee that your Flexible Couplings arrive safely and on time.

FAQ:

Q1: What is the brand of these Flexible Couplings?

A1: The Flexible Couplings are manufactured under the brand name MW.

Q2: Where are the MW Flexible Couplings made?

A2: These couplings are made in China.

Q3: What types of applications are MW Flexible Couplings suitable for?

A3: MW Flexible Couplings are ideal for connecting shafts in various machinery, accommodating misalignment, and reducing transmission of shock loads in industrial applications.

Q4: Are MW Flexible Couplings compatible with different shaft sizes?

A4: Yes, MW Flexible Couplings come in various sizes and can be selected to fit different shaft diameters as required by your equipment.

Q5: What materials are MW Flexible Couplings made from?

A5: MW Flexible Couplings are typically made from high-quality metal alloys designed to provide durability and flexibility under operational stresses.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200