|

|

|

|

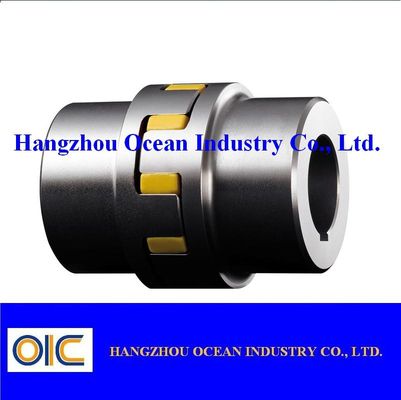

Industrial Machinery Flexible Couplings Providing Flexible Movement and High Torsional Stiffness Ensuring Torque Transfer

| Temperature Range: | Up To 200°C | Torsional Stiffness: | High |

|---|---|---|---|

| Misalignment Capacity: | ±3° | Type: | Flexible |

| Color: | Silver | Material: | Stainless Steel |

| Corrosion Resistance: | High | Size: | Various Sizes Available |

Product Description:

The Flexible Couplings are essential components designed to connect two shafts together while accommodating misalignment and transmitting torque efficiently in industrial machinery. Engineered with precision, these couplings provide a reliable solution for a wide range of mechanical power transmission applications, ensuring smooth operation and longevity of equipment.

One of the key features of these Flexible Couplings is their impressive misalignment capacity of ±3°. This allows them to compensate for angular, parallel, and axial misalignments that commonly occur between connected shafts due to installation errors, thermal expansion, or operational vibrations. This flexibility helps prevent undue stress on the shafts and associated machinery components, reducing maintenance needs and extending service life.

Designed primarily for use in industrial machinery, these couplings excel in environments where robust performance and durability are paramount. They are suitable for various applications including pumps, compressors, conveyors, mixers, and other heavy-duty industrial equipment. The ability to handle a maximum torque of 500 Nm makes them ideal for moderate to high-power transmission tasks, ensuring reliable and efficient power transfer without slippage or loss of motion.

Vibration damping is another critical advantage offered by these Flexible Couplings. The design incorporates features that absorb and mitigate vibrations generated during machine operation. This not only protects the connected equipment from vibration-induced wear and tear but also contributes to quieter operation and improved overall system stability. The vibration damping capability is particularly beneficial in reducing the risk of damage to sensitive components and enhancing operator comfort in industrial settings.

Constructed from high-quality stainless steel, these couplings offer excellent resistance to corrosion, wear, and harsh environmental conditions. Stainless steel’s durability ensures long-lasting performance even in demanding industrial environments where exposure to moisture, chemicals, and temperature fluctuations is common. This material choice also provides superior strength and reliability, making the couplings suitable for continuous heavy-duty use.

The product range includes various types of flexible couplings to meet diverse application needs. One notable variant is the Flexible Element Coupling, which utilizes an elastomeric element to provide flexibility and damping. This design is particularly effective in absorbing shocks and vibrations while accommodating misalignment, making it ideal for applications requiring smooth torque transmission with minimal backlash.

Another popular type is the Aluminum Flexible Coupling, known for its lightweight construction and excellent corrosion resistance. Aluminum couplings are favored in applications where reducing the overall weight of machinery components is crucial without compromising strength and flexibility. Their lightweight nature also contributes to lower inertia, enhancing response times and dynamic performance of the connected equipment.

Additionally, the Flexible Gear Coupling is a robust option designed for high-torque applications. This coupling type features interlocking gears that provide positive torque transmission while allowing for slight misalignments. The gear coupling design is well-suited for heavy industrial machinery where high torque capacity and durability are essential.

In summary, these Flexible Couplings combine versatility, durability, and advanced engineering to meet the demanding requirements of industrial machinery applications. With a ±3° misalignment capacity, vibration damping features, and a maximum torque rating of 500 Nm, they ensure reliable power transmission and protection of connected components. The stainless steel construction guarantees resistance to corrosion and wear, making these couplings a dependable choice for long-term industrial use. Whether opting for the flexible element coupling, aluminum flexible coupling, or flexible gear coupling, users can expect enhanced performance, reduced maintenance, and improved operational efficiency across a wide range of mechanical systems.

Features:

- Product Name: Flexible Couplings

- High torsional stiffness for optimal performance

- Operates efficiently within a temperature range up to 200°C

- Capable of handling misalignment capacity of ±3°

- Maximum torque rating of 500 Nm

- Effective vibration damping to reduce mechanical stress

- Compatible with Hydraulic Coupling systems

- Suitable for use with Fire Hose Couplings

- Designed to work seamlessly with Drum Gear Coupling applications

Technical Parameters:

| Max Speed | 10,000 RPM |

| Size | Various Sizes Available |

| Certifications | ISO 9001, CE |

| Type | Flexible |

| Misalignment Capacity | ±3° |

| Installation Method | Bolt-on |

| Temperature Range | Up To 200°C |

| Torsional Stiffness | High |

| Corrosion Resistance | High |

| Max Torque | 500 Nm |

Applications:

The MW Flexible Couplings, manufactured in China, are designed to meet a wide range of industrial and mechanical application needs. Known for their high torsional stiffness and robust construction from premium stainless steel, these couplings ensure reliable and durable performance in demanding environments. The silver-colored, bolt-on installation method and flange connection type make the MW Flexible Couplings versatile and easy to integrate into various machinery setups.

One of the primary application occasions for MW Flexible Couplings is in hydraulic systems where Hydraulic Coupling components are essential. Their high torsional stiffness allows for efficient transmission of torque while minimizing vibration and misalignment issues, which is critical in hydraulic hose couplings that must maintain a secure and leak-free connection under high pressure. These couplings are ideal for connecting hydraulic hoses to pumps, valves, and other hydraulic components in mobile machinery, industrial equipment, and agricultural machinery.

Additionally, the MW Flexible Couplings serve excellently in scenarios involving Aluminum Flexible Coupling alternatives where stainless steel strength and corrosion resistance are required. Their flange-type connection provides a sturdy and stable interface suitable for heavy-duty applications such as mining equipment, construction machinery, and manufacturing conveyors. The bolt-on installation method simplifies maintenance and replacement, reducing downtime in critical operations.

In industrial automation and robotics, MW Flexible Couplings are used to connect motor shafts and gearboxes, ensuring precise torque transmission and accommodating slight misalignments without compromising system integrity. Their stainless steel material makes them suitable for food processing and pharmaceutical equipment where hygiene and corrosion resistance are paramount.

Moreover, MW Flexible Couplings are utilized in marine and offshore applications where exposure to harsh environments demands materials with high corrosion resistance and mechanical strength. The stainless steel construction and flange connection type provide durability against seawater corrosion and mechanical stress, making them a reliable choice for hydraulic hose couplings in marine hydraulic systems.

Overall, the flexibility, strength, and ease of installation of MW Flexible Couplings make them indispensable in a variety of applications ranging from hydraulic systems, industrial machinery, to specialized environments requiring Aluminum Flexible Coupling alternatives. Their design ensures optimal performance and longevity, supporting a wide array of mechanical and hydraulic coupling needs.

Customization:

MW offers customized Flexible Couplings designed to meet your specific industrial needs. Manufactured in CHINA from high-quality stainless steel, our couplings provide excellent corrosion resistance and can operate at a maximum speed of 10,000 RPM. With a misalignment capacity of ±3°, these flexible rubber couplings ensure reliable performance even under challenging conditions. The flange connection type guarantees secure and easy installation. Whether you require Hydraulic Hose Couplings or Aluminum Flexible Coupling options, MW’s flexible couplings deliver durability and flexibility tailored to your applications.

Support and Services:

Our Flexible Couplings are designed to provide reliable and efficient performance in a variety of industrial applications. To ensure optimal operation and longevity of your flexible couplings, we offer comprehensive technical support and services.

Our technical support team is available to assist with product selection, installation guidance, troubleshooting, and maintenance recommendations. We provide detailed product documentation, including installation manuals, performance data, and maintenance instructions to help you get the most out of your flexible couplings.

In addition, we offer customized solutions tailored to your specific application requirements, including special sizes, materials, and configurations. Our engineering experts are ready to collaborate with you to optimize coupling performance and address any unique challenges.

We also provide repair and refurbishment services to extend the life of your flexible couplings, ensuring minimal downtime and cost savings. Regular inspection and preventive maintenance programs are available to help you maintain peak equipment performance.

For further assistance, please refer to our online resources, including FAQs, technical articles, and instructional videos. Our commitment is to support your operational success through high-quality flexible couplings and responsive technical service.

Packing and Shipping:

Our Flexible Couplings are carefully packaged to ensure maximum protection during transit. Each coupling is wrapped in protective material and placed in a sturdy, corrugated cardboard box to prevent damage from impacts and vibrations. For bulk orders, couplings are securely arranged in custom pallets with additional cushioning to maintain product integrity.

We offer multiple shipping options to accommodate your needs, including standard ground, expedited, and international shipping. All shipments are tracked, and customers receive a tracking number upon dispatch to monitor delivery status. Our logistics partners are chosen for their reliability and efficiency to ensure your Flexible Couplings arrive on time and in excellent condition.

FAQ:

Q1: What is the brand name of the flexible couplings?

A1: The brand name of the flexible couplings is MW.

Q2: Where are the MW flexible couplings manufactured?

A2: The MW flexible couplings are made in China.

Q3: Do the MW flexible couplings have a specific model number?

A3: No, the MW flexible couplings do not have a specific model number.

Q4: What materials are used to make MW flexible couplings?

A4: MW flexible couplings are typically made from high-quality, durable materials such as steel or aluminum to ensure flexibility and strength.

Q5: What applications are suitable for MW flexible couplings?

A5: MW flexible couplings are suitable for various mechanical and industrial applications where torque transmission between shafts with slight misalignment is required.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200