|

|

|

|

Flexible Agricultural Quick Couplings ISO 9001 Certified Offering Long Service Life and Operation in Agricultural Settings

| Max Torque: | 500 Nm | Installation Method: | Bolt-on |

|---|---|---|---|

| Misalignment Capacity: | ±3° | Max Speed: | 10,000 RPM |

| Torsional Stiffness: | High | Material: | Stainless Steel |

| Connection Type: | Flange | Application: | Industrial Machinery |

Product Description:

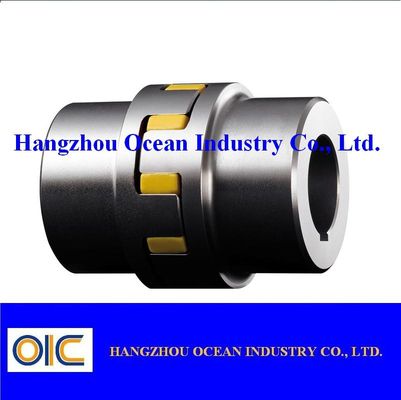

The Flexible Couplings product is an advanced mechanical component designed to provide efficient and reliable connection between rotating shafts in various industrial applications. Engineered to accommodate a wide range of operational demands, this coupling type excels in performance and durability, making it an ideal choice for systems requiring high precision and flexibility.

One of the standout features of this Flexible Couplings product is its impressive maximum speed capability of up to 10,000 RPM. This high-speed capacity ensures that the coupling can perform effectively in high-speed machinery and equipment without compromising stability or safety. Whether utilized in manufacturing, automotive, or heavy-duty industrial settings, these couplings maintain consistent functionality even under demanding rotational speeds.

Flexibility is a key attribute of this coupling, providing a misalignment capacity of ±3°. This allows the coupling to compensate for minor angular, parallel, and axial misalignments between connected shafts, reducing stress on the machinery and preventing premature wear or failure. The ability to accommodate such misalignment is crucial in maintaining smooth operation and extending the service life of both the coupling and the connected components.

As a type of flexible coupling, this product is designed to absorb shocks and vibrations that occur during operation. Its high torsional stiffness plays a pivotal role in transmitting torque efficiently while minimizing backlash and torsional vibrations. This characteristic is essential in applications where precise torque transmission and minimal angular displacement are required, such as in robotics, pumps, and conveyor systems.

The Flexible Couplings product is manufactured to meet stringent quality standards, holding certifications such as ISO 9001 and CE. These certifications attest to the product’s compliance with international quality management systems and safety regulations, providing assurance of reliability and consistent performance. Customers can trust that the coupling adheres to rigorous manufacturing protocols, ensuring longevity and operational excellence.

In addition to its core mechanical properties, this coupling product is compatible with a variety of hydraulic systems. It is particularly suitable for use with Hydraulic Hose Couplings and Hydraulic Coupling assemblies, where flexibility and durability are paramount. The coupling’s design facilitates easy integration with hydraulic components, improving system responsiveness and reducing maintenance requirements.

Moreover, the product’s versatility extends to applications involving Ball Joint Coupling mechanisms. The flexible nature of the coupling complements the ball joint’s ability to allow angular movement, making it an excellent pairing for dynamic systems requiring multi-directional flexibility. This synergy enhances overall system adaptability and performance in complex mechanical configurations.

In summary, the Flexible Couplings product offers a robust solution for connecting rotating shafts in environments that demand high-speed operation, misalignment tolerance, and torsional stiffness. Its compatibility with Hydraulic Hose Couplings, Hydraulic Coupling assemblies, and Ball Joint Coupling systems makes it a versatile addition to a wide range of industrial applications. Backed by ISO 9001 and CE certifications, this coupling guarantees quality, safety, and reliability, making it an indispensable component for modern mechanical and hydraulic systems.

Features:

- Product Name: Flexible Couplings

- Material: Stainless Steel

- Color: Silver

- Type: Flexible

- High Torsional Stiffness for optimal performance

- Maximum Torque Capacity: 500 Nm

- Ideal for Automotive Coupling applications

- Compatible with Hydraulic Quick Coupling systems

- Includes GR Coupling features for enhanced durability

Technical Parameters:

| Type | Flexible |

| Size | Various Sizes Available |

| Color | Silver |

| Torsional Stiffness | High |

| Vibration Damping | Yes |

| Connection Type | Flange |

| Application | Industrial Machinery (including Automotive Coupling, Agricultural Quick Couplings, Grid Spring Coupling) |

| Installation Method | Bolt-on |

| Temperature Range | Up To 200°C |

| Max Speed | 10,000 RPM |

Applications:

The MW Flexible Couplings, proudly manufactured in China, are engineered to meet the demanding needs of various industrial applications. Known for their durability and high performance, these couplings are ideal for scenarios where vibration damping and flexibility are crucial. The MW coupling series includes GR Coupling, Flexible Element Coupling, and Flexible Gear Coupling varieties, each designed to accommodate different mechanical requirements and operating conditions.

In manufacturing plants, MW Flexible Couplings excel in connecting rotating shafts while compensating for misalignment and reducing vibration. This capability is essential in heavy machinery such as pumps, compressors, and conveyors, where maintaining smooth operation at speeds up to 10,000 RPM is vital. The stainless steel construction ensures robustness and resistance to wear, corrosion, and extreme environmental factors, making them suitable for harsh industrial environments.

The temperature tolerance of up to 200°C allows MW Flexible Couplings to be used in high-temperature applications such as automotive exhaust systems, power generation equipment, and chemical processing plants. Their ability to perform under thermal stress ensures longevity and consistent performance, reducing downtime and maintenance costs.

These couplings are also widely used in the aerospace and defense sectors, where precision and reliability are paramount. The flexible gear coupling variant is particularly effective in transmitting high torque while allowing for angular and axial misalignment, which is common in aircraft engines and defense machinery.

With various sizes available, MW Flexible Couplings can be tailored to fit a broad range of equipment, from small precision instruments to large industrial machinery. The Flexible Element Coupling provides excellent shock absorption and noise reduction, making it suitable for applications requiring smooth and quiet operation, such as HVAC systems and automation equipment.

Overall, the MW brand’s Flexible Couplings offer a comprehensive solution for mechanical power transmission across multiple industries. Their combination of vibration damping, high-speed capability, temperature resistance, and durable stainless steel materials ensures reliable performance in diverse application occasions and scenarios.

Customization:

MW offers professional product customization services for our Flexible Couplings, designed to meet diverse industrial needs. Manufactured in CHINA, our flexible couplings accommodate a misalignment capacity of ±3°, ensuring reliable performance in various applications. With a temperature range of up to 200°C, these couplings are suitable for demanding environments. Available in various sizes, our bolt-on installation method allows for easy and secure fitting. Whether you require Drum Gear Coupling, Flexible Rubber Coupling, or Hydraulic Coupling, MW provides tailored solutions to match your specific requirements and optimize operational efficiency.

Support and Services:

Our Flexible Couplings are designed to provide reliable performance and ease of maintenance in a variety of industrial applications. For technical support, our team of experts is available to assist with installation guidance, troubleshooting, and product selection to ensure optimal operation.

We offer comprehensive services including custom engineering solutions, on-site inspections, and preventative maintenance programs tailored to extend the life of your flexible couplings. Replacement parts and upgrades are readily available to enhance compatibility and performance.

To maximize the efficiency and durability of your flexible couplings, we recommend following the provided installation instructions and adhering to the maintenance schedule. Our support resources include detailed manuals, FAQs, and instructional videos accessible through our online portal.

Whether you require assistance during the initial setup or ongoing operational support, our dedicated technical service team is committed to providing timely and effective solutions to meet your needs.

Packing and Shipping:

Our Flexible Couplings are carefully packaged to ensure maximum protection during transit. Each coupling is wrapped in protective material and placed in a sturdy, corrugated cardboard box designed to prevent damage from impacts and vibrations.

For bulk orders, couplings are securely packed in reinforced cartons with appropriate cushioning to avoid movement and abrasion. All packages are clearly labeled with product details, handling instructions, and shipping information to facilitate smooth delivery.

We offer multiple shipping options to meet your needs, including standard, expedited, and freight services. Each shipment is tracked from our warehouse to your specified destination to ensure timely and safe arrival.

Our packaging and shipping processes comply with international standards to guarantee that our Flexible Couplings reach you in perfect condition, ready for immediate use.

FAQ:

Q1: What is a flexible coupling?

A1: A flexible coupling is a mechanical device used to connect two shafts together at their ends for the purpose of transmitting power. It accommodates slight misalignments and reduces shock loads between connected equipment.

Q2: What brand manufactures this flexible coupling?

A2: This flexible coupling is manufactured by the brand MW.

Q3: Where is the MW flexible coupling made?

A3: The MW flexible coupling is made in China.

Q4: Does the MW flexible coupling support shaft misalignment?

A4: Yes, the flexible design of the MW coupling allows it to accommodate slight angular, parallel, and axial misalignments between connected shafts.

Q5: Is there a specific model number for this MW flexible coupling?

A5: No, this MW flexible coupling does not have a specific model number.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

Flange Coupling, type 224 , 250 , 280 , 315 , 355 , 400 , 450 , 560 , 630

-

Double cardanic type DKM Coupling , Size 38 , 42 , 48 MM

-

Chain Coupling, type 5018 , 6018 , 6020 , 6022 , 8018 , 8020

-

Cast Material Rotex Coupling ,Size 19 , 24 , 28 , 38 , 42 MM

-

Nylon Sleeve Flexible Coupling NL1 / NL2 / NL3 / NL4 / NL5 / NL6 / NL7 / NL8 / NL9 / NL10

-

Flange Coupling, type 90 , 100 , 112 , 125 , 140 , 160 , 180 , 200