|

|

|

|

30000 Units Heavy Duty Shelf Racks Industrial Machinery Steel Storage Racks Offering Support and Warehouse Organization

| Module: | 1.0 | Accuracy: | DIN 6 |

|---|---|---|---|

| Length: | 1000mm | Surface Treatment: | Black Oxide |

| Shape: | Rack Gear | Ability: | 30000 Units |

| Tooth Profile: | Straight | Color: | Nature |

Product Description:

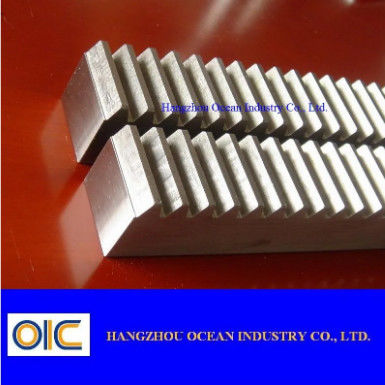

Gear Racks are essential components widely used in various mechanical systems, particularly in sliding gate motors, to facilitate smooth and efficient linear motion. These racks play a critical role in converting rotational motion into linear movement, which is fundamental for the operation of sliding gates. Manufactured with precision and designed to meet high-performance standards, our Gear Racks ensure durability, reliability, and high efficiency in every application.

One of the standout features of our Gear Racks is their impressive production capacity, with an ability to produce up to 30,000 units. This large-scale manufacturing capability guarantees a steady supply for industrial and commercial needs, making them a dependable choice for both small and large projects. Whether you are outfitting a new sliding gate system or replacing existing components, these racks provide consistent quality and longevity.

Specifically engineered for sliding gate motor usage, these Gear Racks offer exceptional compatibility and performance. Sliding gates require robust and precise components to operate smoothly and safely, and our Gear Racks meet these stringent requirements. The racks are designed to withstand the stresses and strains typical of gate operation, ensuring that gates open and close effortlessly and reliably over long periods.

In terms of dimensions, each Gear Rack measures 1000mm in length and 20mm in width, a size that balances strength with ease of installation. This length is ideal for a wide range of sliding gate sizes, providing ample coverage and support for smooth gate movement. The 20mm width contributes to the rack’s structural integrity, allowing it to endure significant operational loads without deformation or wear.

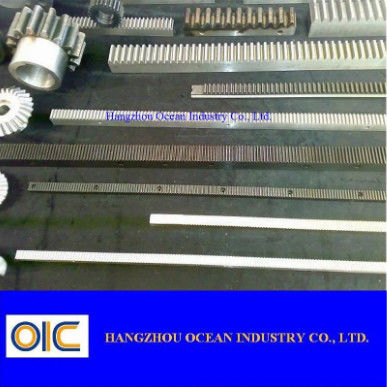

Our Gear Racks come in various types, often referred to as “Kinds OF” to emphasize the diversity available to meet different application needs. This means you can select the specific type of rack that best suits your gate motor system, whether it requires a particular tooth profile, material composition, or mounting style. This versatility makes our product line adaptable to a broad spectrum of mechanical setups and customer preferences.

Euro Racks, a popular variant within our Gear Rack offerings, are particularly notable for their precision and quality. These Euro Racks are manufactured using advanced Gear Mold technology, which ensures uniform tooth geometry and excellent surface finish. The use of specialized Gear Mold processes results in racks that engage smoothly with pinions, reducing noise and mechanical wear. Euro Racks are favored in many European and international markets for their reliability and performance.

The Gear Mold technology employed in producing these racks is a key factor that sets them apart from ordinary gear components. By utilizing high-precision molds, the racks achieve consistent tooth profiles and enhanced durability. This manufacturing method not only improves the operational efficiency of sliding gate motors but also extends the lifespan of the gear racks, minimizing maintenance and replacement costs.

In summary, our Gear Racks represent a high-quality, reliable solution for sliding gate motor applications. With a large production capacity of 30,000 units, dimensions tailored for optimal performance (1000mm length and 20mm width), and a variety of types available, these racks are engineered to meet diverse operational demands. The inclusion of Euro Racks, crafted through advanced Gear Mold technology, further underscores our commitment to providing superior products that enhance the functionality and longevity of sliding gate systems. Whether for new installations or replacements, our Gear Racks deliver the precision, durability, and efficiency necessary for smooth, dependable gate operation.

Features:

- Product Name: Gear Racks

- Width: 20mm

- Tooth Profile: Straight for precise and efficient power transmission

- Accuracy: DIN 6 ensuring high dimensional accuracy and quality

- Processing Method: Hobbing for superior tooth surface finish

- Usage: Ideal for Sliding Gate Motor applications

- Heavy Duty Racking designed to withstand demanding operational conditions

- Available in both Straight and Helical Gear Racks to suit various mechanical needs

Technical Parameters:

| Processing | Hobbing |

| Module | 1M |

| Application | Industrial Machinery |

| Shape | Rack Gear |

| Accuracy | DIN 6 |

| Tooth Profile | Straight |

| Condition | New |

| Usage | Sliding Gate Motor |

| Ability | 30000 Units |

| Width | 20mm |

Applications:

The MW Gear Racks, model M4, originating from China, are precision-engineered components designed to meet the demands of various industrial and commercial applications. Manufactured through advanced hobbing processing, these gear racks feature a straight tooth profile that ensures reliable and smooth engagement with pinions, providing optimal performance in mechanical power transmission systems. With a length of 1000mm, the MW Gear Racks are versatile and suitable for a broad range of heavy-duty applications.

One of the key application occasions for the MW Gear Racks is in the construction of Heavy Duty Racking systems. These racks require components that can withstand substantial loads and continuous use without compromising structural integrity. The robust design and high manufacturing standards of the MW M4 gear racks make them ideal for integration into heavy-duty racking solutions used in warehouses, manufacturing plants, and distribution centers. Their ability to handle high torque and stress ensures that the racks remain stable and secure while supporting heavy loads.

In addition to Heavy Duty Racking, the MW Gear Racks are perfectly suited for use in Heavy Bag Rack systems. These systems often involve the handling of heavy materials stored in bags or sacks, necessitating racks that can endure significant weight and frequent movement. The gear racks’ precise tooth profile and durable construction contribute to smooth operation and long-lasting reliability in these environments, reducing maintenance needs and downtime.

The MW Heavy Duty Rack solutions leverage the strength and precision of the M4 Gear Racks to offer outstanding performance in various machinery and equipment designs. Whether it is for automation systems, material handling equipment, or custom heavy-duty machinery, these gear racks provide the necessary rigidity and accuracy. With an impressive production capacity of 30,000 units, MW ensures consistent availability for large-scale projects and industrial demands.

Overall, the MW Gear Racks model M4 are essential components in scenarios where heavy-duty mechanical strength and durability are paramount. Their combination of high-quality hobbing processing, straight tooth profile, and suitability for heavy load-bearing applications like Heavy Duty Racking, Heavy Bag Rack, and Heavy Duty Rack systems make them a dependable choice for engineers and designers worldwide.

Customization:

MW presents the M4 model Gear Racks, expertly crafted in CHINA to deliver exceptional performance and durability. These Heavy Duty Steel Racks are designed with precision using advanced Gear Mold technology, ensuring superior strength and reliability for various industrial applications. With a module size of 1M and a length of 1000mm, the M4 Gear Racks offer versatile sizing to fit different configurations and requirements. As a new product, the M4 model supports a wide range of types, making it suitable for multiple uses including as a Heavy Bag Rack in storage and transport systems. MW guarantees an impressive production ability of 30,000 units, ensuring availability and consistent quality for all your heavy-duty gearing needs.

Support and Services:

Our Gear Racks product is designed to provide reliable and efficient performance in various mechanical applications. For technical support, please ensure that you have the product model number and specifications ready when seeking assistance.

We offer comprehensive services including installation guidance, maintenance tips, troubleshooting, and replacement parts availability to ensure optimal operation of your Gear Racks.

For installation, follow the detailed instructions provided in the user manual to ensure proper alignment and secure mounting. Regular lubrication and inspection are recommended to maintain smooth operation and extend the lifespan of the gear racks.

If you experience any issues such as unusual noise, wear, or misalignment, consult the troubleshooting section of the manual or contact our technical support team for expert assistance.

We are committed to providing high-quality support and services to help you maximize the performance of your Gear Racks product.

Packing and Shipping:

Our Gear Racks are carefully packaged to ensure maximum protection during transit. Each rack is securely wrapped with protective materials to prevent scratches and damage. The packaging includes sturdy cardboard boxes and foam inserts to keep the product stable and safe.

For shipping, we use reliable carriers with tracking options to provide timely delivery. We offer various shipping methods to accommodate your needs, including standard, expedited, and international shipping. Each order is inspected before dispatch to guarantee the highest quality and customer satisfaction.

FAQ:

Q1: What is the brand name of the Gear Racks?

A1: The Gear Racks are manufactured under the brand name MW.

Q2: What is the model number of this Gear Rack?

A2: The model number for this Gear Rack is M4.

Q3: Where are MW Gear Racks manufactured?

A3: MW Gear Racks are made in China.

Q4: What materials are used to make the MW M4 Gear Rack?

A4: The MW M4 Gear Rack is typically made from high-quality steel for durability and strength.

Q5: What applications are suitable for the MW M4 Gear Rack?

A5: The MW M4 Gear Rack is suitable for various mechanical and industrial applications requiring precise linear motion and power transmission.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378