|

|

|

|

High Corrosion Resistance Chain Mesh Conveyor Belt Including 1 Years Guarantee Perfect for Robust and Material Handling

| Speed: | 50 Feet Per Minute | Load Capacity: | 5000 Lbs |

|---|---|---|---|

| Powder Recovery Rate: | 99.4% | Corrosion Resistance: | High |

| Standard: | ISO | Maintenance: | Low |

| Ganrantee: | 1years | Booth: | PP/PVC |

Product Description:

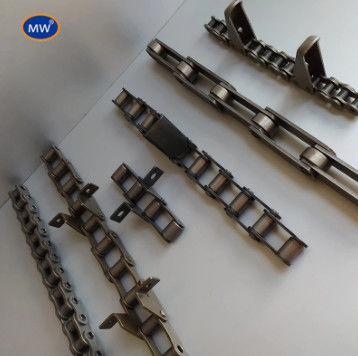

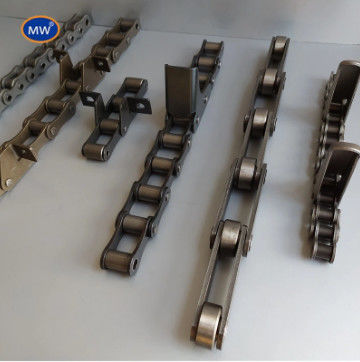

The Conveyor Chains are an essential component designed to enhance the efficiency and reliability of material handling systems across various industries. Manufactured to meet the stringent ISO standards, these conveyor chains are engineered to deliver exceptional performance, durability, and load-bearing capacity. Specifically tailored for use in Grain Chain Conveyor systems, these chains ensure smooth and consistent operation, playing a vital role in the transportation of bulk materials such as grains, powders, and other granular products.

One of the standout features of these conveyor chains is their impressive load capacity of up to 5000 lbs, making them suitable for heavy-duty applications. This high load capacity ensures that the chains can handle substantial weights without compromising on speed or reliability, which is crucial for industries that require continuous and efficient material flow. Whether it is in agricultural settings, food processing plants, or industrial manufacturing lines, these conveyor chains offer dependable performance that withstands the rigors of demanding environments.

The versatility of these conveyor chains is further highlighted by their compatibility with various curing ovens, including gas, electricity, and diesel-powered ovens. This adaptability ensures that the conveyor chains can be integrated seamlessly into different production setups, allowing for optimal curing processes that improve the overall quality of the products being handled. By supporting multiple curing oven types, these conveyor chains provide manufacturers with the flexibility to select the most suitable curing method for their specific requirements.

The pretreatment of the conveyor chains is executed using high-quality materials such as PVC, PP, and SUS, which contribute significantly to their durability and resistance to corrosion. PVC (Polyvinyl Chloride) and PP (Polypropylene) provide excellent chemical resistance and mechanical strength, making the chains ideal for environments where exposure to moisture, chemicals, or abrasive substances is common. SUS (Stainless Steel) treatment further enhances the chains’ resilience, ensuring longevity even under harsh operating conditions. This combination of materials guarantees that the conveyor chains maintain their integrity and performance over extended periods of use.

In addition to the conveyor chains themselves, the product line includes compatible Conveyor Chain Sprockets, which are crucial for the smooth transmission of motion and force within the conveyor system. These sprockets are precisely engineered to mesh perfectly with the conveyor chains, reducing wear and tear while ensuring efficient power transfer. The synergy between the conveyor chains and sprockets minimizes downtime and maintenance costs, thereby increasing overall productivity.

Moreover, Conveyor Chain Sprockets are available in various sizes and configurations to accommodate different conveyor system designs, allowing for customization to meet specific operational needs. This flexibility ensures that industries can optimize their conveyor setups for maximum efficiency and reliability. When paired with the robust conveyor chains, these sprockets form a comprehensive solution that supports continuous and trouble-free material handling operations.

In summary, these Conveyor Chains are a high-quality, ISO-standardized solution designed for heavy-duty material handling applications. With a load capacity of 5000 lbs, compatibility with multiple curing oven types, and pretreatment using durable materials like PVC, PP, and SUS, they offer unmatched strength and longevity. The inclusion of Conveyor Chain Sprockets further enhances the system’s efficiency, making these products ideal for Grain Chain Conveyor applications and beyond. Investing in these conveyor chains ensures a reliable, efficient, and long-lasting conveyor system capable of meeting the rigorous demands of modern industrial processes.

Features:

- Product Name: Conveyor Chains

- High corrosion resistance suitable for industrial environments

- Operating speed of 50 feet per minute for efficient material handling

- Chain width of 2 inches, ideal for various conveyor feeder systems

- Length of 10 feet to accommodate diverse industrial chain conveyor setups

- 1-year guarantee ensuring product reliability and performance

- Designed for use in Industrial Chain Conveyor and Conveyor Feeder Systems

Technical Parameters:

| Type | Conveyor Chain |

| Length | 10 Feet |

| Load Capacity | 5000 Lbs |

| Noise Level | Low |

| Corrosion Resistance | High |

| Powder Recovery Rate | 99.4% |

| Standard | ISO |

| Maintenance | Low |

| Booth | PP/PVC |

| Curing Oven | Gas/electricity/diesel |

Applications:

The MW Conveyor Chains, proudly manufactured in China, are essential components designed to enhance the efficiency and reliability of various conveyor systems. With a width of 2 inches and a length of 10 feet, these chains are engineered to provide optimal performance in diverse industrial applications. Their high corrosion resistance makes them particularly suitable for environments where exposure to moisture, chemicals, or other corrosive elements is common, ensuring longevity and durability even under demanding conditions.

These conveyor chains serve as a vital conveyor accessory, seamlessly integrating into conveyor sorting systems to facilitate smooth and precise material handling. They are ideal for use in industries such as manufacturing, packaging, food processing, and logistics, where efficient sorting and transportation of goods are critical. Whether you are operating a gas, electricity, or diesel curing oven, the MW Conveyor Chains can withstand the operational stresses and maintain consistent performance, supporting continuous production workflows.

The versatility of MW Conveyor Chains allows them to be employed in various application occasions including assembly lines, distribution centers, and automated sorting facilities. Their robust construction ensures they can handle heavy loads and frequent usage without compromising the conveyor system's functionality. Additionally, the product comes with a one-year guarantee, reflecting MW’s commitment to quality and customer satisfaction.

In conveyor sorting systems, precise movement and alignment are crucial. MW Conveyor Chains provide the reliability needed to maintain these standards, reducing downtime and maintenance costs. Their design not only promotes smooth conveyor belt operation but also contributes to overall system efficiency, making them indispensable for businesses aiming to optimize their material handling processes.

In summary, the MW Conveyor Chains are an outstanding conveyor accessory designed to meet the rigorous demands of modern conveyor systems. Their high corrosion resistance, appropriate dimensions, and compatibility with various curing ovens make them a preferred choice for industries seeking durable and efficient conveyor solutions. By integrating these chains into your conveyor sorting systems, you can ensure enhanced productivity and long-term operational success.

Customization:

MW offers customized Conveyor Chains designed to meet the specific needs of your Chain Conveyor Systems. Manufactured in China, our Conveyor Components are made using high-quality PVC, PP, or SUS materials through advanced pretreatment processes to ensure durability and performance. With a standard width of 2 inches and capable of operating at speeds up to 50 feet per minute, these Cylinder Conveyor Chains are ideal for efficient material handling. Our curing ovens utilize gas, electricity, or diesel to guarantee consistent quality. All products adhere to ISO standards, ensuring reliability and excellence in every chain conveyor solution.

Support and Services:

Our Conveyor Chains product is supported by a dedicated technical support team committed to ensuring optimal performance and longevity of your conveyor systems. We offer comprehensive services including installation guidance, maintenance tips, troubleshooting assistance, and replacement part recommendations. Our experts are available to help you select the right chain type and configuration to meet your specific application requirements. Additionally, we provide detailed product documentation and technical resources to assist with proper chain handling, lubrication, and inspection procedures. Rely on our support services to maximize efficiency and minimize downtime in your material handling operations.

Packing and Shipping:

Our Conveyor Chains are carefully packaged to ensure maximum protection during transit. Each chain is wrapped in rust-preventive paper and securely placed in sturdy wooden crates or heavy-duty cardboard boxes, depending on the size and quantity of the order. The packaging is designed to prevent any damage from moisture, dust, or impact.

For shipping, we offer multiple options including sea freight, air freight, and land transportation to meet your delivery requirements. All shipments are thoroughly inspected before dispatch to guarantee the highest quality standards. Tracking information will be provided to keep you updated on the status of your order until it reaches your destination safely.

FAQ:

Q: What is the brand name of the conveyor chains?

A: The conveyor chains are branded as MW.

Q: Where are MW conveyor chains manufactured?

A: MW conveyor chains are made in China.

Q: Are there specific model numbers for MW conveyor chains?

A: No, MW conveyor chains do not have specific model numbers.

Q: What types of conveyor chains does MW offer?

A: MW offers a variety of conveyor chains suitable for different industrial applications, including steel chains, plastic chains, and custom chains.

Q: Can MW conveyor chains be used in heavy-duty applications?

A: Yes, MW conveyor chains are designed to handle heavy-duty applications and are built for durability and long service life.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

short pitch / long pitch roller Conveyor chain with High precision

-

Hollow Pin Chain , type C2042HP C2052HP C2062HP C2082HP C2042H-HP C2052H-HP C2062H-HP C2082H-HP

-

Hollow pin chain , type 08BP , 40HP , 50HPSS , 60HP

-

Stainless Steel Straight Run Flat-Top Chain, type LF820-K325 LF820-K350 LF820-K400

-

Stainless Steel Sideflex Flat-top Chain, type 882TAB-K750 , 882TAB-K1000 , 882TAB-K1200

-

Stainless Steel Sideflex Flat-top Chain, type 880TAB-K325 880TAB-K325 882TAB-K500 882TAB-K600