|

|

|

|

Rack Gear Heavy Duty Steel Racks Featuring 20mm Width Ideal for Warehouse Storage and Heavy Load Industrial Applications

| Module: | 1.0 | Mod: | 1M |

|---|---|---|---|

| Tooth Profile: | Straight | Usage: | Sliding Gate Motor |

| Type: | Kinds OF | Application: | Industrial Machinery |

| Surface Treatment: | Black Oxide | Length: | 1000mm |

Product Description:

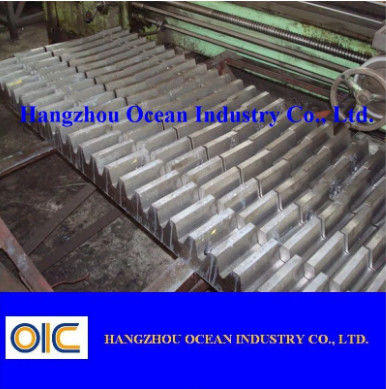

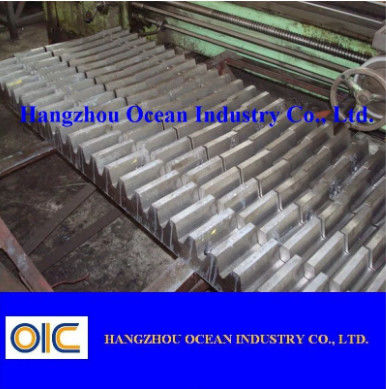

Gear racks are essential components widely utilized in industrial machinery to convert rotational motion into linear motion with precision and reliability. Among the various types available, CC Racks stand out for their robust construction and exceptional performance in demanding applications. These racks are designed to meet the rigorous requirements of heavy-duty operations, making them an indispensable choice for industries requiring durable and efficient motion transmission solutions.

One of the key features of these gear racks is their natural color, which reflects the high-quality raw materials used in their manufacture. The natural finish not only provides an aesthetic appeal but also ensures resistance to corrosion and wear, thereby extending the service life of the racks even in harsh industrial environments. This characteristic makes them suitable for use in a wide range of machinery, from heavy bag racks to complex automated systems.

The gear racks come in various kinds, catering to different industrial needs. Their versatility allows them to be employed in applications ranging from light-duty equipment to heavy-duty racking systems. This adaptability is largely due to the precise processing method used – hobbing. Hobbing is a specialized gear manufacturing technique that produces highly accurate and smooth-toothed racks, ensuring seamless meshing with pinions and minimizing operational noise and vibration. The precision achieved through hobbing enhances the overall efficiency and reliability of the mechanical systems in which these gear racks are installed.

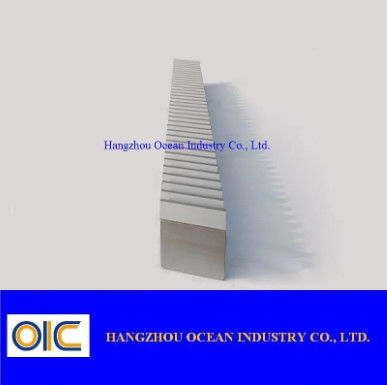

With a standard width of 20mm, these gear racks provide a balanced combination of strength and compactness. The 20mm width is optimal for a variety of industrial machinery setups, offering sufficient surface area for load distribution while maintaining a manageable size for integration into existing systems. This dimension supports the heavy-duty nature of the racks, allowing them to withstand substantial forces without compromising structural integrity.

In heavy bag rack applications, these gear racks prove invaluable due to their ability to handle significant loads and repetitive motion cycles with minimal wear. Their heavy-duty racking capabilities ensure that the machinery operates smoothly and efficiently, reducing downtime and maintenance costs. The robustness of the gear racks also contributes to enhanced safety in industrial operations, as they maintain consistent performance under strenuous conditions.

Furthermore, the CC Racks are engineered to provide long-term durability and performance stability. Their design and manufacturing process emphasize quality and precision, making them suitable for integration into various industrial machinery types. Whether used in conveyor systems, automated assembly lines, or material handling equipment, these gear racks deliver reliable linear motion control, which is critical for maintaining productivity and operational accuracy.

In conclusion, gear racks with a 20mm width, natural color, and processed through hobbing represent a superior choice for industrial machinery applications. Their availability in different kinds allows customization according to specific operational needs, while their heavy-duty racking capabilities ensure resilience and longevity. The inclusion of CC Racks and heavy bag rack options further highlights the product's versatility and suitability for demanding industrial environments. By choosing these gear racks, industries can achieve enhanced mechanical efficiency, reduced maintenance efforts, and improved overall system performance.

Features:

- Product Name: Gear Racks

- Color: Nature

- Condition: New

- Surface Treatment: Black Oxide

- Processing Method: Hobbing

- Shape: Rack Gear

- High precision CNC Gear Rack for reliable performance

- Ideal for heavy duty racking applications

- Durable equipment component designed for long-lasting use

Technical Parameters:

| Module | 1.0 |

| Condition | New |

| Shape | Rack Gear |

| Accuracy | DIN 6 |

| Surface Treatment | Black Oxide |

| Application | Industrial Machinery |

| Usage | Sliding Gate Motor |

| Type | Kinds OF |

| Width | 20mm |

| Color | Nature |

| Keywords | Heavy Bag Rack, CNC Gear Rack, Euro Racks |

Applications:

The MW Gear Racks, model number M4, originating from China, are essential components designed primarily for use in sliding gate motor systems. With a length of 1000mm and a natural color finish, these gear racks are crafted to deliver exceptional performance and durability in various industrial and commercial applications. As new and high-quality gear spare parts, they ensure smooth and reliable operation of sliding gate motors, making them indispensable for both maintenance and new installations.

One of the most common application occasions for the MW Gear Racks is in the automation of sliding gates, where precise and consistent movement is critical. These gear racks are engineered to mesh perfectly with pinion gears, facilitating efficient motion transfer and minimizing wear and tear. Their robust construction allows them to withstand the stresses encountered in heavy-duty operations, making them suitable for both residential and commercial sliding gate systems.

Beyond sliding gates, these gear racks find extensive use in various industrial environments, especially where heavy duty shelf racks and heavy duty racking systems are involved. In warehouses and manufacturing facilities, gear racks like the MW M4 model play a crucial role in automated storage and retrieval systems. Their strength and reliability make them ideal for supporting the movement of heavy loads on racking systems, enhancing operational efficiency and safety.

The versatility of the MW Gear Racks extends to other machinery and equipment that require precise linear motion control. Whether used in conveyor systems, material handling equipment, or custom-built automation solutions, these gear spare parts provide dependable service. Their natural color and standard length facilitate easy integration into existing systems, while their new condition guarantees long service life and minimal maintenance needs.

In summary, the MW M4 Gear Racks are perfect for a variety of application scenarios, ranging from sliding gate motors to heavy duty shelf racks and heavy duty racking setups. Their durability, precision, and compatibility make them a preferred choice for industries seeking reliable mechanical components. Whether upgrading current systems or designing new ones, these gear racks offer a cost-effective and efficient solution to meet demanding operational requirements.

Customization:

MW Gear Racks, model number M4, are precision-engineered heavy duty shelf racks designed to enhance your equipment setup. Manufactured in China, these gear racks feature a length of 1000mm and an accuracy rating of DIN 6, ensuring reliable and smooth operation. With a module size of 1M and a natural color finish, these racks are ideal for supporting heavy bag rack applications and other industrial uses. MW offers an impressive production ability of 30,000 units, guaranteeing availability for large scale projects.

Support and Services:

Our Gear Racks are designed to deliver high precision and durability for various industrial applications. For technical support, please ensure that you have the product specifications and application details ready to facilitate a swift resolution.

We offer comprehensive services including installation guidance, maintenance tips, and troubleshooting advice to maximize the performance and lifespan of your Gear Racks. Our technical team is equipped to assist with customization requests and compatibility assessments to meet your specific needs.

For optimal performance, regularly inspect the Gear Racks for wear and lubrication requirements. Follow the recommended maintenance schedule provided in the product manual to prevent unexpected downtime.

Should you encounter any issues or require further assistance, our support resources include detailed documentation and FAQs available on our website. We are committed to providing timely and effective solutions to ensure your complete satisfaction with our Gear Racks.

Packing and Shipping:

Our Gear Racks are carefully packaged to ensure they arrive in perfect condition. Each rack is securely wrapped with protective materials to prevent scratches and damage during transit. The product is then placed in a sturdy, appropriately sized box with cushioning to absorb any shocks or impacts.

For shipping, we partner with reliable carriers to provide timely and safe delivery. Tracking information will be provided once your order has been dispatched, allowing you to monitor the shipment until it reaches your doorstep. We also offer various shipping options to accommodate your needs, including expedited and standard delivery services.

FAQ:

Q1: What brand manufactures the Gear Racks model M4?

A1: The Gear Racks model M4 is manufactured by the brand MW.

Q2: Where are the MW Gear Racks M4 produced?

A2: The MW Gear Racks model M4 are made in China.

Q3: What applications are suitable for the MW Gear Racks M4?

A3: The MW Gear Racks M4 are suitable for various mechanical and industrial applications requiring precise linear motion and power transmission.

Q4: What materials are used in the construction of the MW Gear Racks M4?

A4: The MW Gear Racks M4 are typically made from high-quality steel to ensure durability and strength.

Q5: Can the MW Gear Racks M4 be customized to specific lengths or specifications?

A5: Yes, MW offers customization options for the Gear Racks M4 to meet specific length or design requirements. Please contact the supplier for more details.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378