|

|

|

|

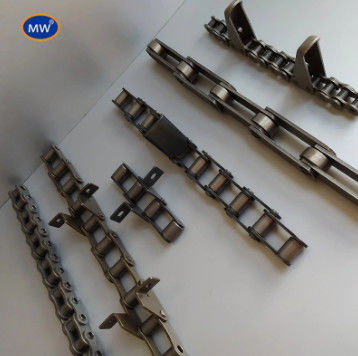

Low Maintenance Conveyor Chains 10 Feet Length ISO Standard Corrosion Resistant Conveyor Chain for Harsh Environments

| Width: | 2 Inches | Load Capacity: | 5000 Lbs |

|---|---|---|---|

| Curing Oven: | Gas/electricity/diesel | Pretreatment: | PVC/PP/SUS Material |

| Maintenance: | Low | Type: | Conveyor Chain |

| Corrosion Resistance: | High | Booth: | PP/PVC |

Product Description:

Our Conveyor Chains are engineered to deliver exceptional performance and reliability in a wide range of industrial applications. Designed as a critical component of Chain Conveyor Systems, these chains ensure smooth and efficient material handling, making them an indispensable asset for manufacturing and processing operations. With a robust load capacity of 5000 lbs, our Conveyor Chains can handle heavy-duty tasks with ease, supporting substantial weights without compromising on durability or performance.

One of the standout features of our Conveyor Chains is their low maintenance requirement. Manufactured with high-quality materials and precision engineering, these chains minimize downtime and reduce maintenance costs, allowing businesses to focus on productivity rather than frequent repairs. This low maintenance attribute is particularly beneficial in environments where continuous operation is critical, ensuring that the Chain Conveyor System remains operational with minimal interruptions.

Speed is another crucial factor in conveyor performance, and our Conveyor Chains excel in this regard. Capable of operating at speeds up to 50 feet per minute, they provide consistent and reliable movement of materials through the conveyor system. This speed efficiency helps increase throughput and optimize production cycles, making them ideal for industries where timing and precision are essential.

For applications involving powder materials, our Conveyor Chains offer an impressive powder recovery rate of 99.4%. This high recovery rate ensures minimal material loss during transport, enhancing overall process efficiency and reducing waste. Such performance is especially valuable in industries like pharmaceuticals, chemicals, and food processing, where material conservation and cleanliness are paramount.

Our Conveyor Chains are compatible with various curing ovens, including gas, electricity, and diesel-powered options. This versatility enables seamless integration into different production lines and curing processes, providing flexibility to meet the specific needs of each operation. Whether used in a gas-fired curing oven or an electric or diesel variant, these conveyor chains maintain their integrity and performance under varying temperature conditions, ensuring reliable operation throughout the curing cycle.

Additionally, our Bucket Elevator Conveyor Chain models are designed to facilitate the vertical lifting and movement of bulk materials efficiently. These chains combine strength and durability with smooth operation, supporting the elevation of heavy loads while minimizing wear and tear. The Bucket Elevator Conveyor Chain is an excellent choice for industries requiring vertical conveying solutions, further expanding the versatility of our chain conveyor offerings.

In summary, our Conveyor Chains provide a comprehensive solution for material handling needs within Chain Conveyor Systems. With a high load capacity of 5000 lbs, operational speeds of 50 feet per minute, and an outstanding powder recovery rate of 99.4%, these chains offer a blend of strength, efficiency, and precision. Their low maintenance requirements and compatibility with various curing oven types—including gas, electricity, and diesel-powered ovens—make them a cost-effective and reliable choice for diverse industrial applications. Whether integrated into a standard Chain Conveyor System or employed as a Bucket Elevator Conveyor Chain, these chains are designed to enhance productivity and ensure long-lasting performance.

Applications:

The MW Conveyor Chains, originating from China, are engineered to meet the demanding requirements of modern automated conveyor systems. With a robust design and a width of 2 inches, these chains are perfectly suited for various industrial applications where reliability and efficiency are paramount. The high corrosion resistance of the MW Conveyor Chains ensures long-lasting performance even in harsh environments, making them ideal for industries that handle abrasive or corrosive materials.

One common application of the MW Conveyor Chains is in conveyor sorting systems, where precise and consistent movement is crucial. The chains operate at a speed of 50 feet per minute, providing smooth and controlled material handling that enhances the overall productivity of sorting operations. This speed is optimal for maintaining a steady flow without compromising the accuracy required in sorting processes.

Additionally, the MW Conveyor Chains feature a booth made of PP/PVC, which contributes to their excellent durability and resistance to wear. The material choice also supports a powder recovery rate of 99.4%, which is particularly beneficial in applications involving fine powders or particulate matter. This high recovery rate minimizes waste and improves environmental sustainability within conveyor system operations.

These conveyor chains are widely used in automated conveyor systems across various industries such as manufacturing, packaging, food processing, and pharmaceuticals. Their ability to withstand corrosive conditions while maintaining high performance makes them a preferred choice for businesses looking to optimize their material handling processes. The MW Conveyor Chains not only improve operational efficiency but also reduce maintenance costs due to their durability and corrosion resistance.

In summary, the MW Conveyor Chains are an essential component in conveyor systems where reliability, speed, and material handling precision are critical. Whether integrated into conveyor sorting systems or broader automated conveyor systems, these chains deliver consistent performance, high powder recovery rates, and exceptional corrosion resistance, making them a valuable asset for any industrial application.

Customization:

MW brand Conveyor Chains are designed with high-quality materials and customizable options to meet your specific needs. Although there is no fixed model number, these conveyor chains originate from CHINA and are available with various pretreatment options including PVC, PP, and SUS materials to ensure durability and performance.

The conveyor chains feature booths made from PP or PVC, providing flexibility in application and compatibility with different conveyor systems. With a speed capacity of 50 feet per minute and a width of 2 inches, these conveyor chains are ideal for efficient material handling.

Our customization services extend to the Conveyor Chain Sprocket and other conveyor components, allowing you to tailor the conveyor chain sprocket and related parts to fit your operational requirements perfectly. Whether you need specific sizes, materials, or configurations, MW offers expert customization to optimize your conveyor system's performance.

Support and Services:

Our Conveyor Chains are designed to provide reliable and efficient performance in various industrial applications. To ensure optimal operation and longevity of your conveyor chains, we offer comprehensive technical support and services.

Our technical support team is available to assist with installation guidance, maintenance procedures, and troubleshooting to help you maximize the lifespan and efficiency of your conveyor chains. We provide detailed documentation, including installation manuals, maintenance schedules, and material specifications to support your operational needs.

We also offer custom engineering services to tailor conveyor chain solutions specific to your application requirements. Whether you need chains with special materials, coatings, or custom dimensions, our experts can work with you to develop the ideal product.

Regular maintenance is crucial for conveyor chains to prevent unexpected downtime. We provide inspection services and training programs to help your team identify wear and potential issues early. Replacement parts and upgrades are readily available to keep your conveyor systems running smoothly.

For any technical inquiries or support requests, our specialists are ready to provide prompt and professional assistance to ensure your conveyor chain systems operate at peak performance.

Contact Person: Mrs. Lily Mao

Tel: 008613588811830

Fax: 86-571-88844378

-

short pitch / long pitch roller Conveyor chain with High precision

-

Hollow Pin Chain , type C2042HP C2052HP C2062HP C2082HP C2042H-HP C2052H-HP C2062H-HP C2082H-HP

-

Hollow pin chain , type 08BP , 40HP , 50HPSS , 60HP

-

Stainless Steel Straight Run Flat-Top Chain, type LF820-K325 LF820-K350 LF820-K400

-

Stainless Steel Sideflex Flat-top Chain, type 882TAB-K750 , 882TAB-K1000 , 882TAB-K1200

-

Stainless Steel Sideflex Flat-top Chain, type 880TAB-K325 880TAB-K325 882TAB-K500 882TAB-K600